Detergent feeding device and clothes washing machine

A detergent dispensing and rib technology, applied in the field of washing machines, can solve the problems of cracking of welding seams, affecting the normal operation of the washing machine, and burying hidden dangers for the safety of users, so as to avoid water leakage, improve safety and reliability, and reduce cracking. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

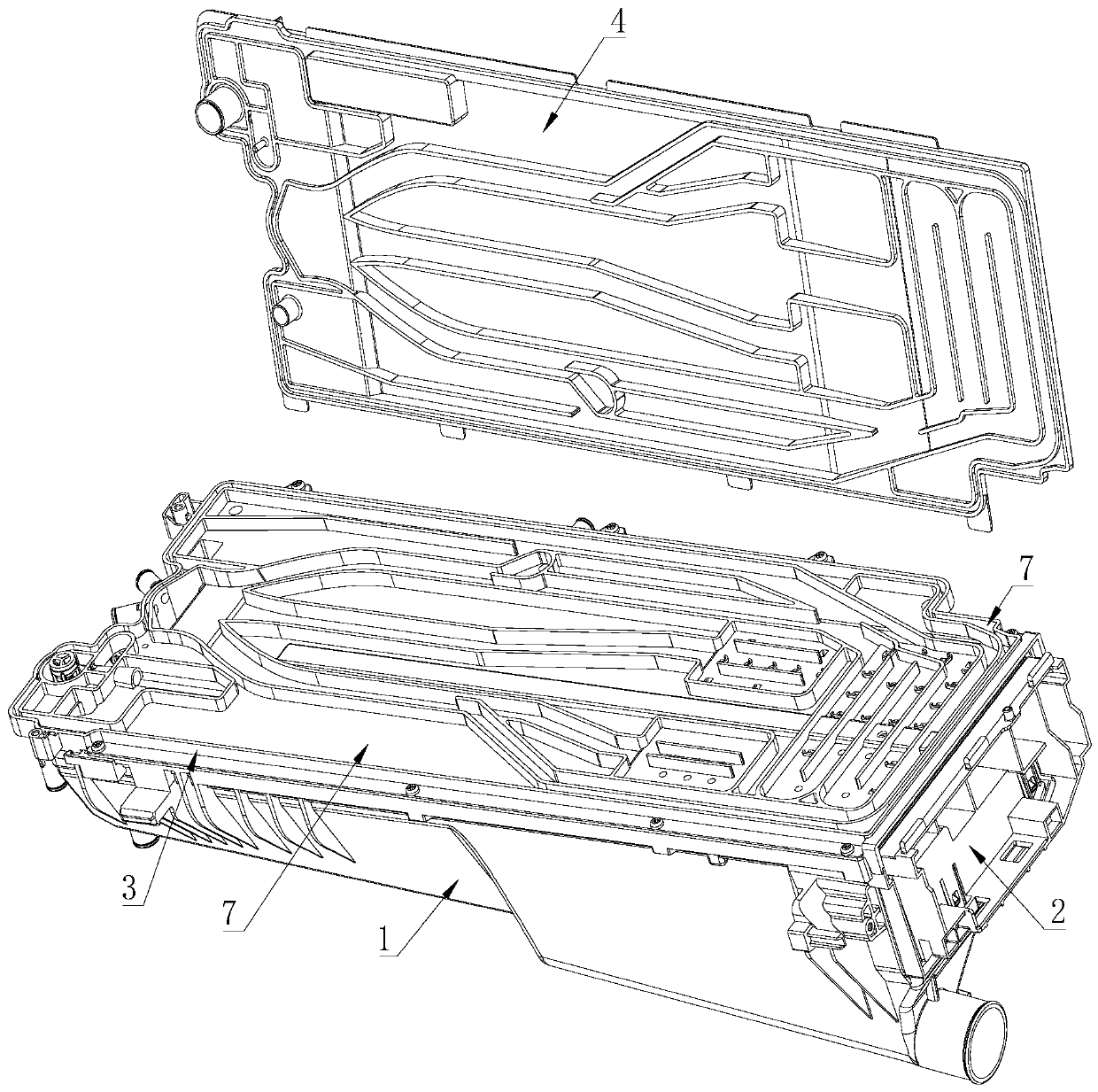

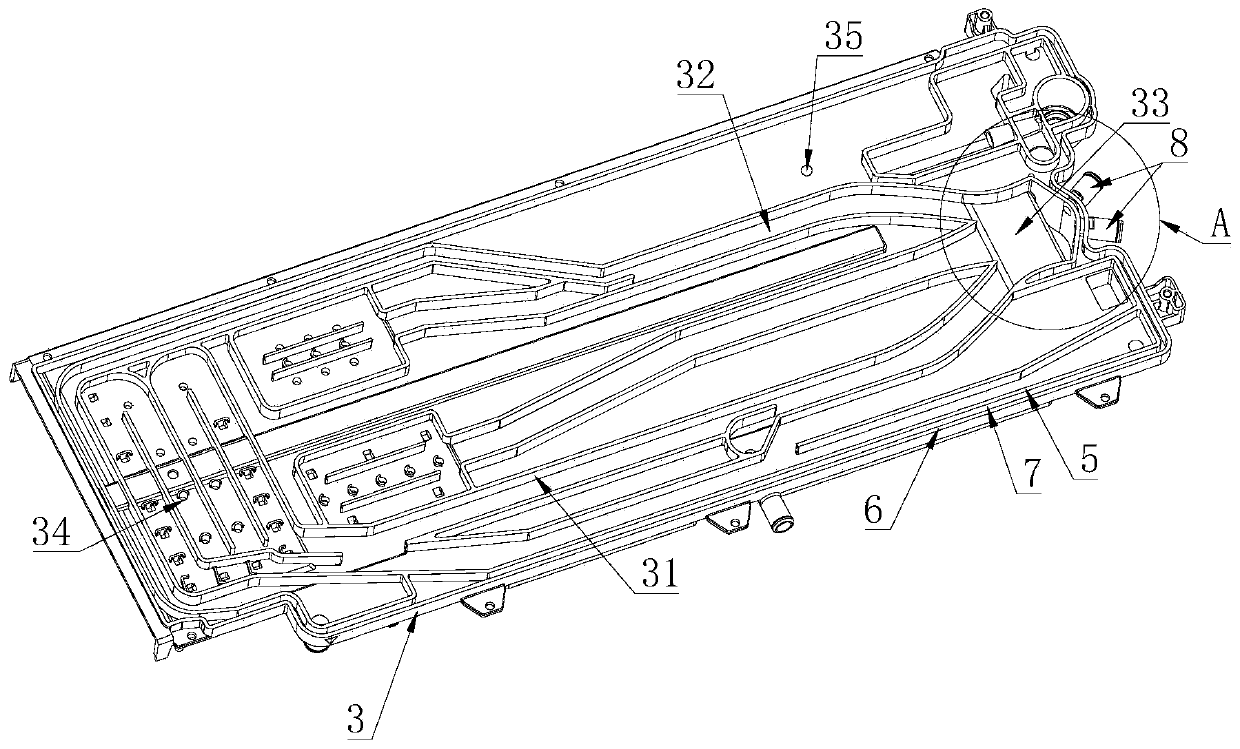

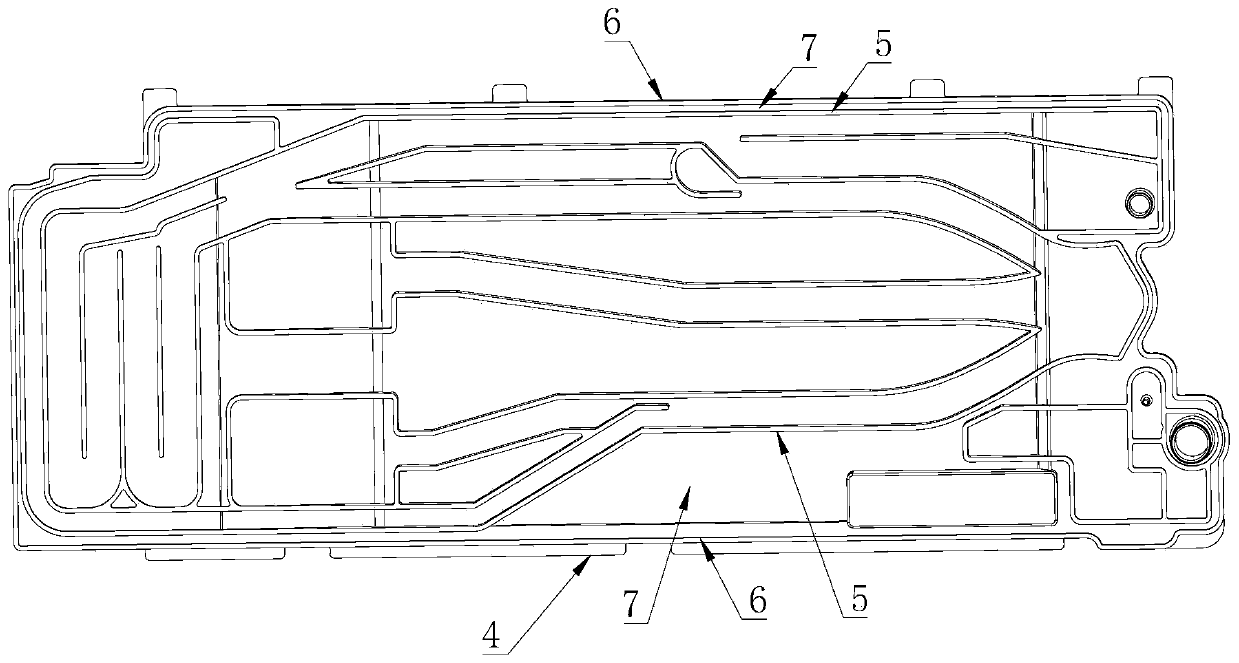

[0031] Such as Figure 1 to Figure 3 As shown, a detergent dispensing device described in the embodiment of the present invention includes a water box 1 and a liquid storage box 2 installed inside the water box 1. The top of the water box 1 is composed of a cover plate, and the inside of the cover plate The hollow chamber is provided with a water inlet flow channel 32 for injecting water into the liquid storage box 2. A circle of inner ribs 5 is arranged on the periphery of the water inlet flow channel 32, and a circle of outer ribs 6 is arranged on the outer periphery of the cover plate. The inner ribs 5 Set apart from the outer rib plate 6 to form a circle of airtight chambers extending along the outer periphery of the cover plate, the entire airtight chamber runs through, the inside of the airtight chamber is provided with a through hole 35, and the airtight chamber communicates with the outside of the cover plate through the through hole 35 .

[0032] In the embodiment of...

Embodiment 2

[0035] Such as Figure 1 to Figure 4 As shown, a detergent dispensing device described in the embodiment of the present invention is installed on a washing machine and automatically dispenses detergent solution into the washing machine. The detergent dispensing device includes a liquid storage box 2 for holding detergent and a The cover plate for water injection in the liquid storage box 2, the cover plate is provided with a water inlet flow channel 32, and the periphery of the water inlet flow channel 32 is provided with an inner rib plate 5 and an outer rib plate 6 arranged at intervals, and the inner rib plate 5 and the outer rib plate 6 forms a circle of continuous airtight chambers, and the ribs on both sides of the airtight chamber separate the water inlet channel 32 from the outside.

[0036] In this embodiment, the cover plate includes a lower cover 3 and an upper cover 4 that are fastened to each other. The upper cover 4 and the lower cover 3 are welded and fixed. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com