Thin-wall hollow pier pouring connecting structure and construction method thereof

A thin-walled hollow pier and connecting structure technology, which is used in construction, bridge parts, erection/assembly of bridges, etc., to achieve the effect of facilitating overall hoisting construction, easy disassembly, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

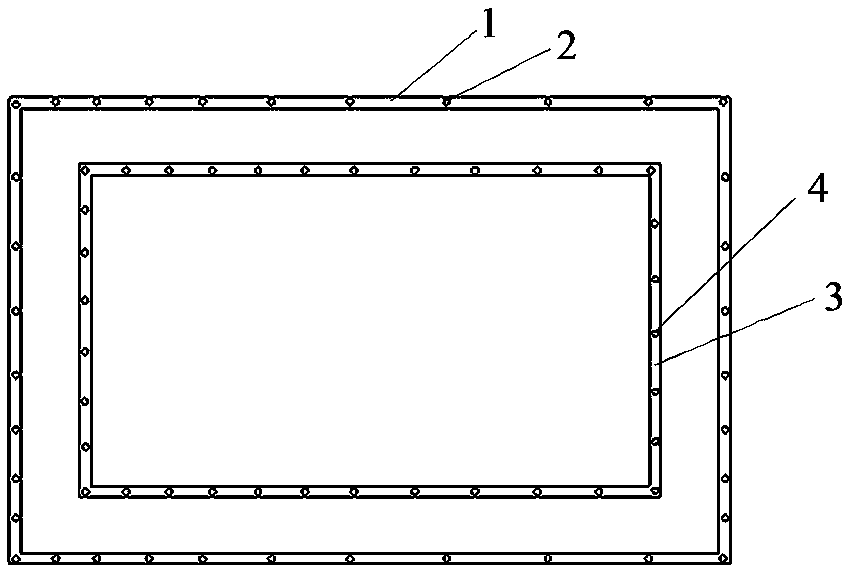

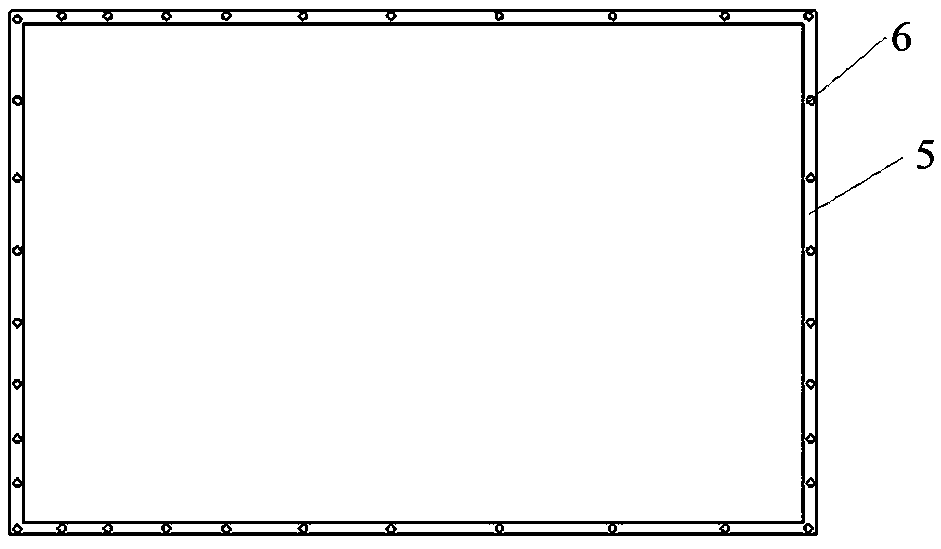

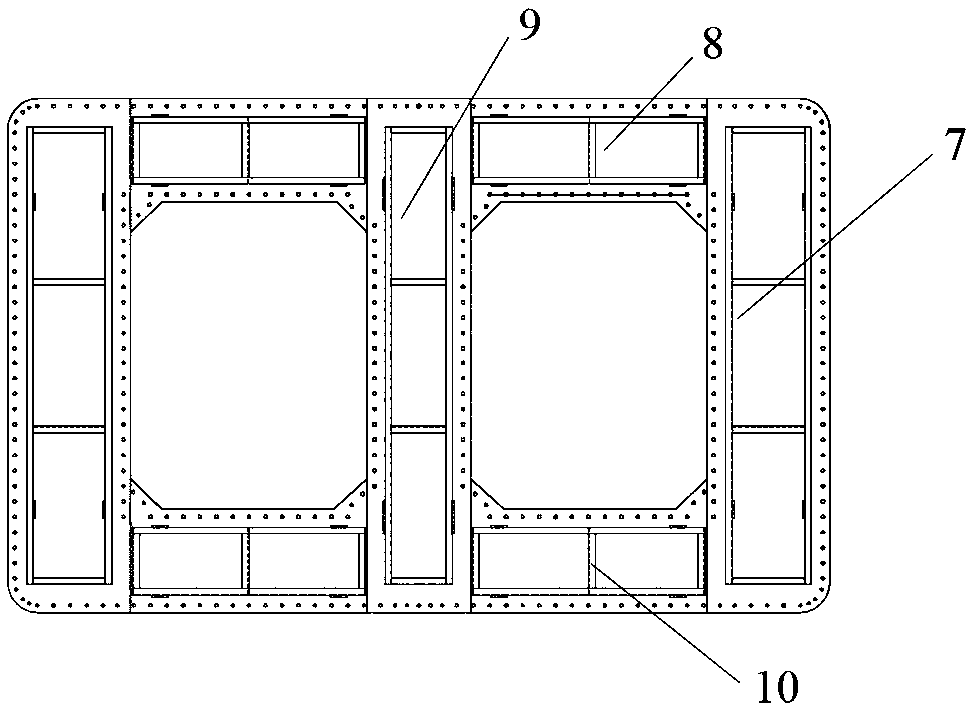

[0038] Taking a pouring structure of a thin-walled hollow pier with double holes as an example, the double holes are rectangular holes of the same size and the four corners are arc-shaped holes arranged horizontally side by side. Hollow thin-walled hollow pier is divided into at least two sections within its height range for segmental installation. The applied thin-walled hollow pier pouring connection structure includes pier steel bars connected by segments, a lower frame body 5 connected to the lower part of the pier steel bars, an upper frame body connected to the upper part of the pier steel bars, a set of formwork connected to the middle part of the pier steel bars, and The formwork attached to the outside of the reinforcement after binding the reinforcement.

[0039] like figure 1 and figure 2 As shown, the lower frame body 5 is a rectangular steel frame made of thick steel plate or angle steel, and the lower frame body 5 is provided with a lower frame fixed hole 6 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com