Prefabricated building sound insulation wall body module and construction method thereof

A prefabricated and architectural technology, applied in the direction of sound insulation, construction, building components, etc., can solve problems such as the inability to transmit sound waves conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

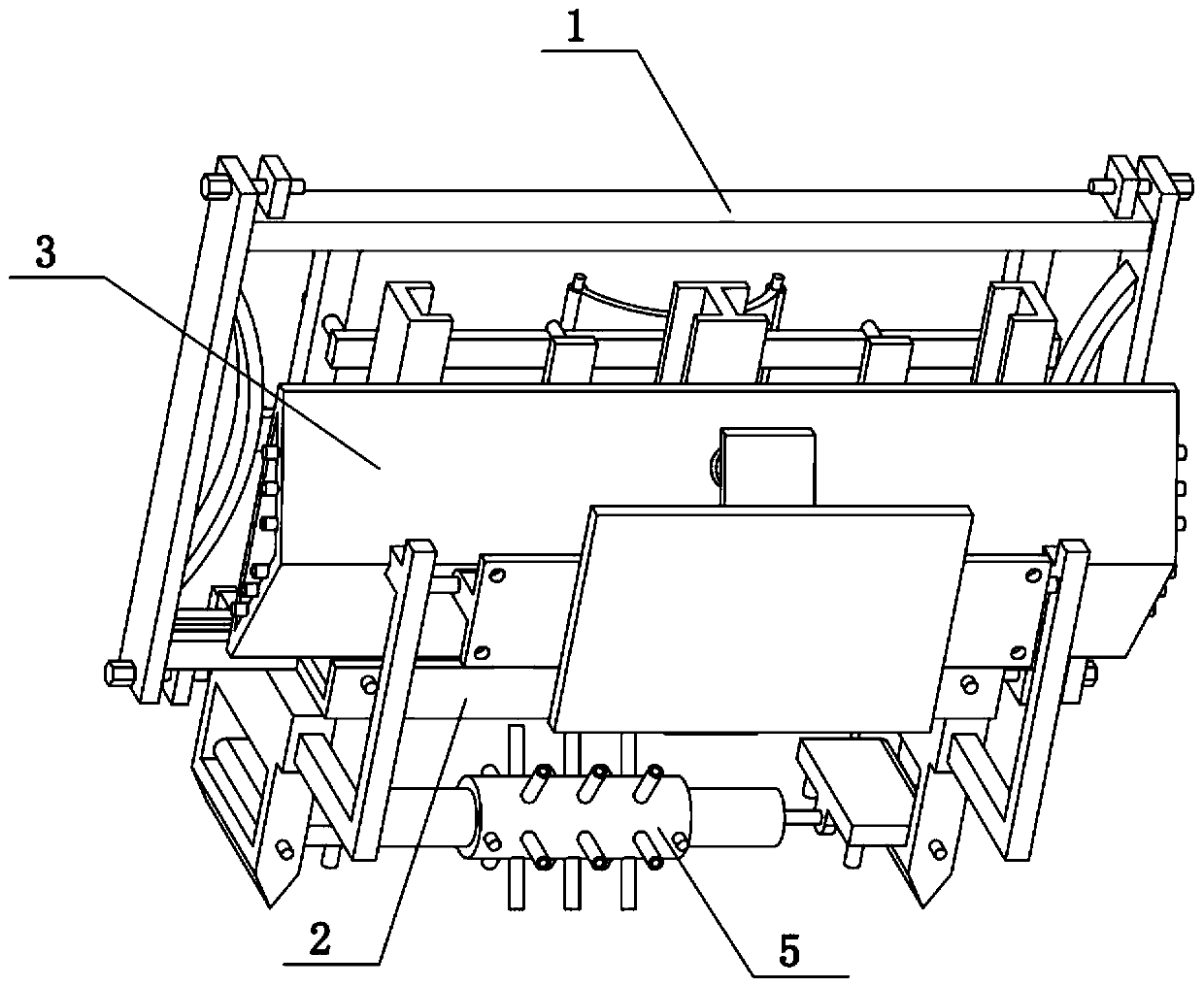

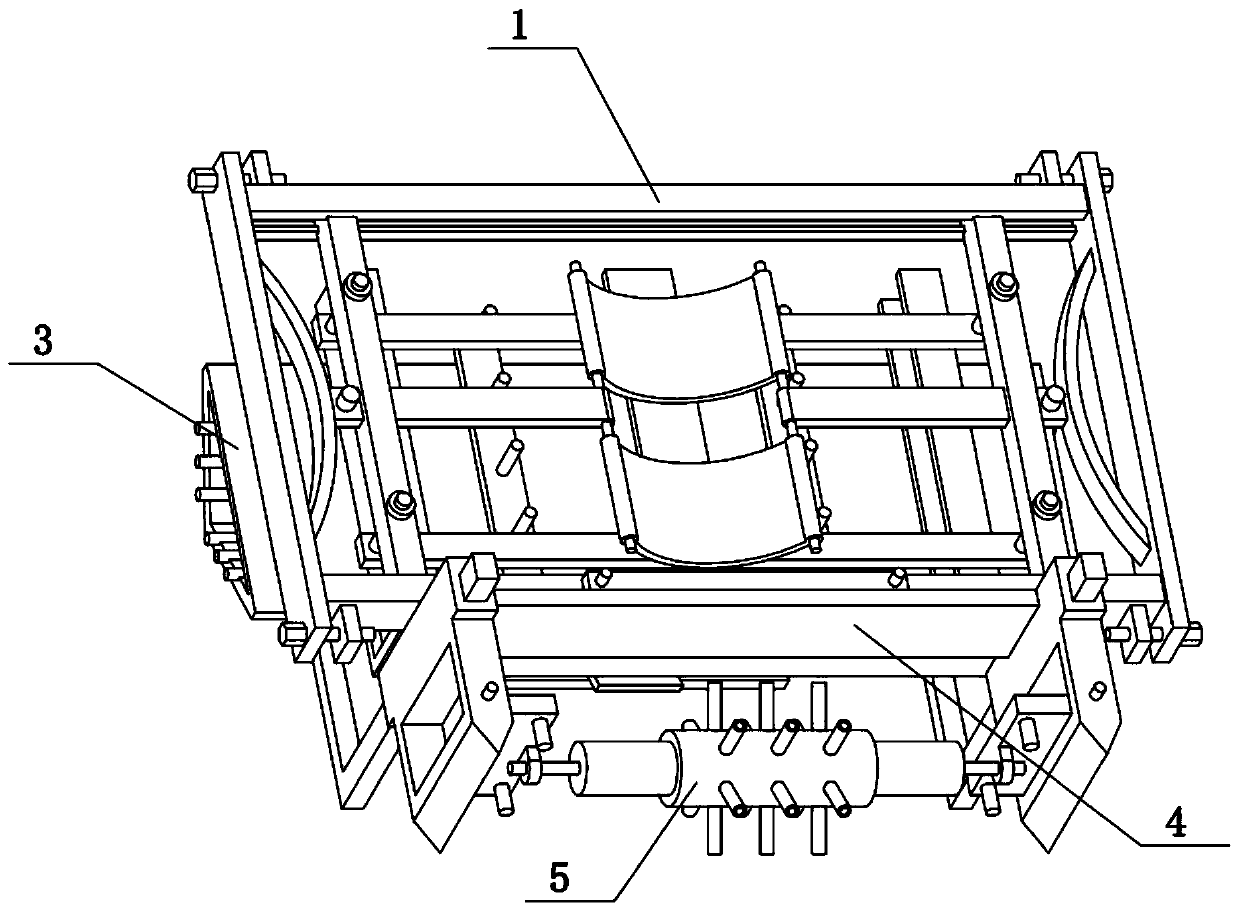

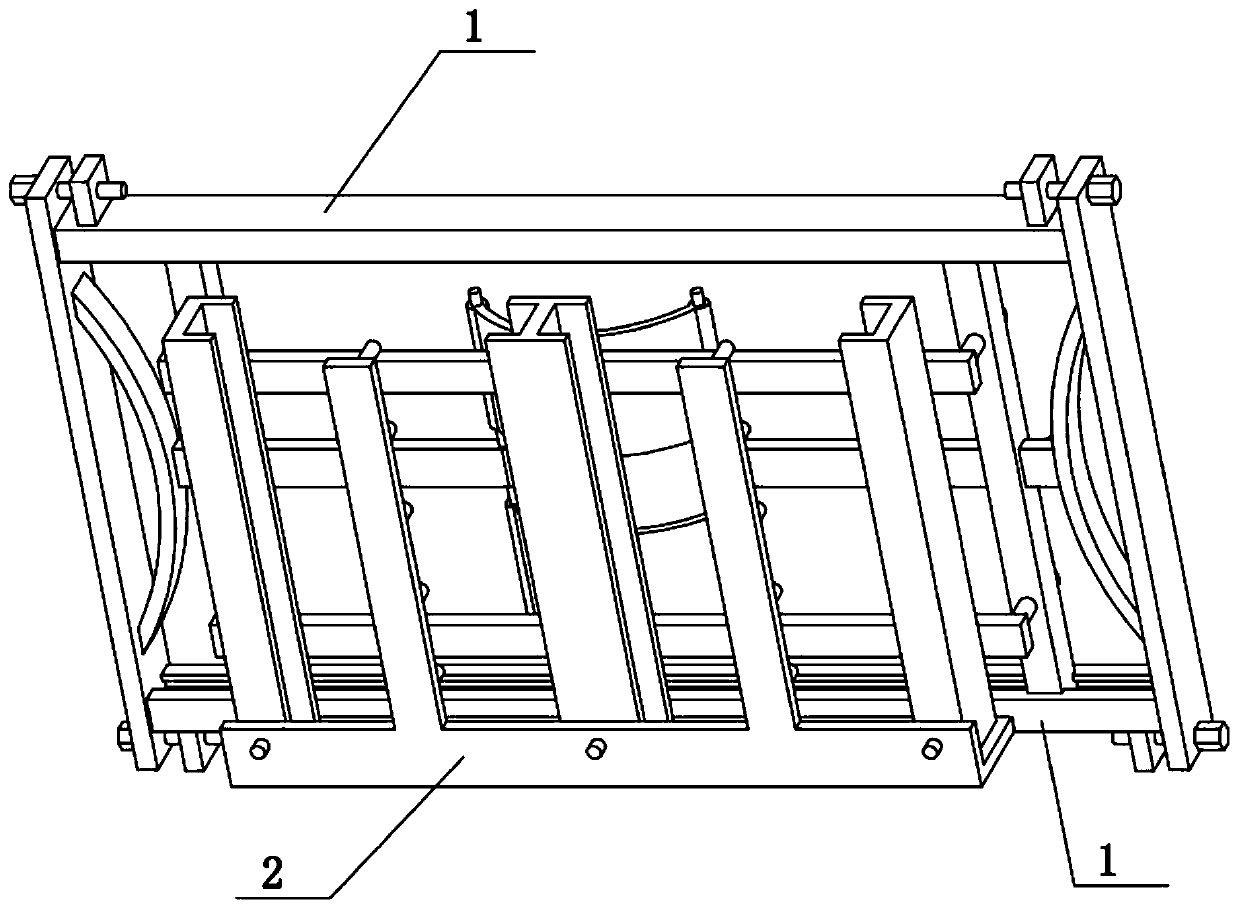

[0034] Combine below Figure 1-10 To illustrate this embodiment, the present invention relates to the field of prefabricated buildings, more specifically, the sound insulation wall modules of prefabricated buildings, including angle steel 2, side groove rods 201, upper fins 202, insertion rods 203 and middle groove rods 204. The invention can facilitate the transmission of sound waves to the sound insulation felt for reduction.

[0035] The upper middle part of the angle steel 2 is fixedly connected with a middle groove bar 204 by screws, and the left and right ends of the upper side of the angle steel 2 are fixedly connected with a side groove rod 201 by screws, and the two side groove rods 201 are all provided with one-sided Vertical grooves, the left and right sides of the middle groove rod 204 are provided with vertical grooves, and sound insulation felts are inserted between the two side groove rods 201 and the middle groove rod 204, and two upper convex pieces 202 are sy...

specific Embodiment approach 2

[0037] Combine below Figure 1-10 To illustrate this embodiment, the prefabricated building sound insulation wall module also includes a cross bar 101, a sliding round bar 102, an arc-shaped shrapnel 105, a vertical column 106, a horizontal sliding bar 107, a vertical shaft 108, a limit ring 110 and a stop pin 111, two vertical columns 106 are arranged on the left and right sides, and the middle parts of the two vertical columns 106 are horizontally slidably connected with a horizontal sliding bar 107, and the outer ends of the two horizontal sliding bars 107 are fixedly connected with a retaining pin 111, and the two horizontal sliding bars The inner ends of 107 are all fixedly connected with the vertical shaft 108 that is arranged vertically, and the upper end of two vertical shafts 108 is provided with arc shrapnel 105, and the lower end of two vertical shafts 108 is provided with arc shrapnel 105, and cross bar 101 is provided with two up and down, and the left and right e...

specific Embodiment approach 3

[0039] Combine below Figure 1-10 To illustrate this embodiment, the prefabricated building sound insulation wall module also includes a horizontal bar 1, an arc-shaped elastic bar 103, a horizontal chute 104 and a vertical bar 109. There are two horizontal bars 1 up and down, and the vertical bar 109 is left and right There are two, two horizontal rods 1 and two vertical rods 109 are fixedly connected to form a rectangular frame, and the two horizontal rods 1 are provided with horizontal chute 104, and the inner sides of the two vertical rods 109 are fixedly connected with arcs. Shaped elastic bar 103, the upper ends of two vertical posts 106 are all slidably connected on the horizontal chute 104 that is positioned at the upper end, and the lower ends of two vertical posts 106 are all slidably connected on the horizontal chute 104 that is positioned at the lower end, two horizontal slide bars The outer ends of 107 abut on the two arc elastic bars 103 respectively. The two cr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap