Online and offline integrated detection machine and detection method

A technology of offline detection and detection machine, applied in the field of detection, can solve the problems of limited to online detection, limited to offline detection, etc., achieve strong economic value, save the cost of detection equipment, and have the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

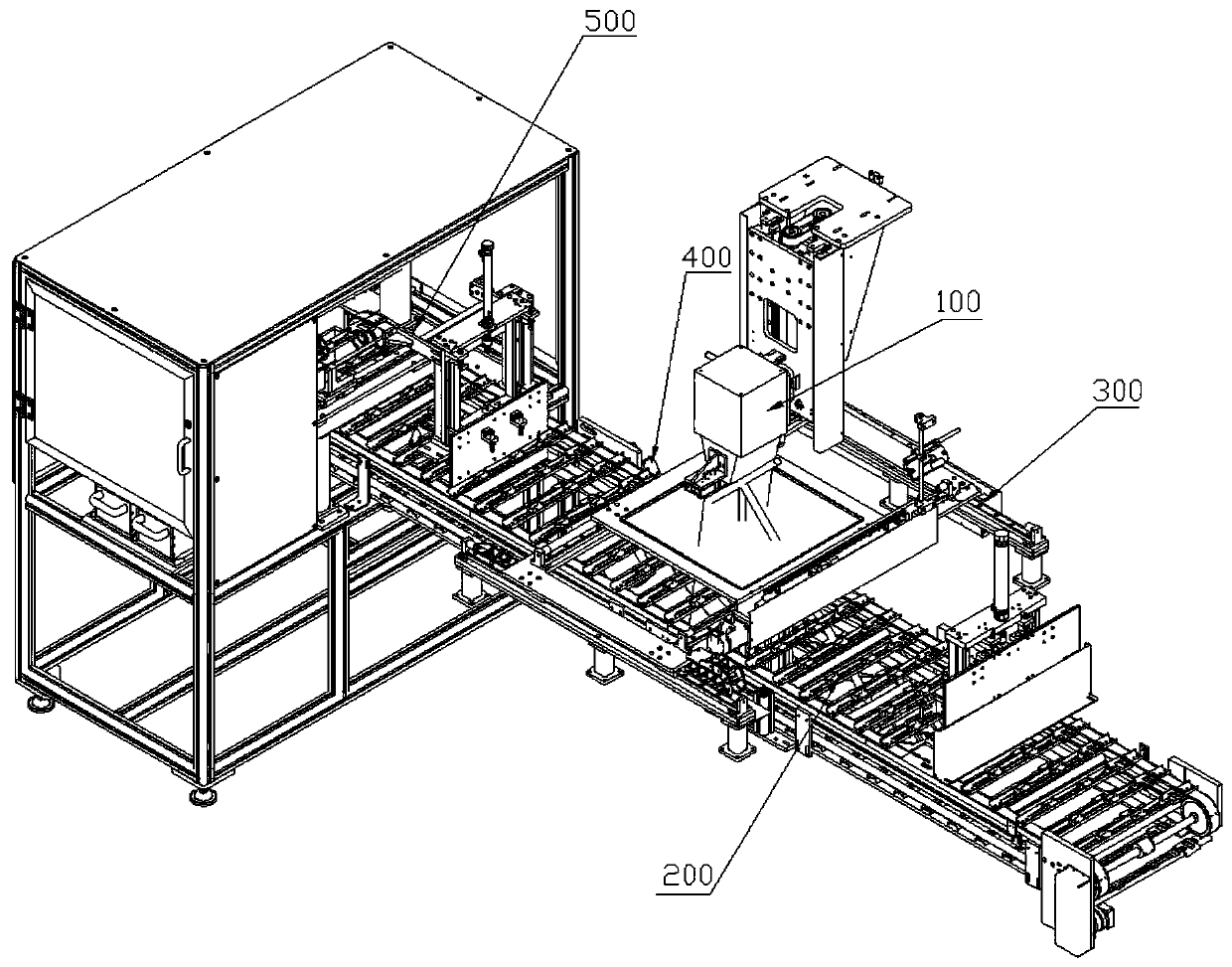

[0064] see figure 1 and Figure 4 As shown, this embodiment provides an online and offline integrated testing machine, which can be used for both online and offline testing of products. On-line inspection means that when products need to be inspected in batches, the products to be inspected are transmitted on the production line. Off-line inspection means that when a small amount of products need to be inspected, the products to be inspected only need to be put into the inspection station (manually or automatically by manipulator) for inspection.

[0065] Specifically, the online and offline integrated detection machine includes:

[0066]The light source device 100 is used to provide the illumination required for detection and irradiate the product to be inspected;

[0067] The online conveying device 200, located below the light source device 100, is used to convey the products to be inspected, and convey the products to be inspected in the previous process to the inspecti...

Embodiment 2

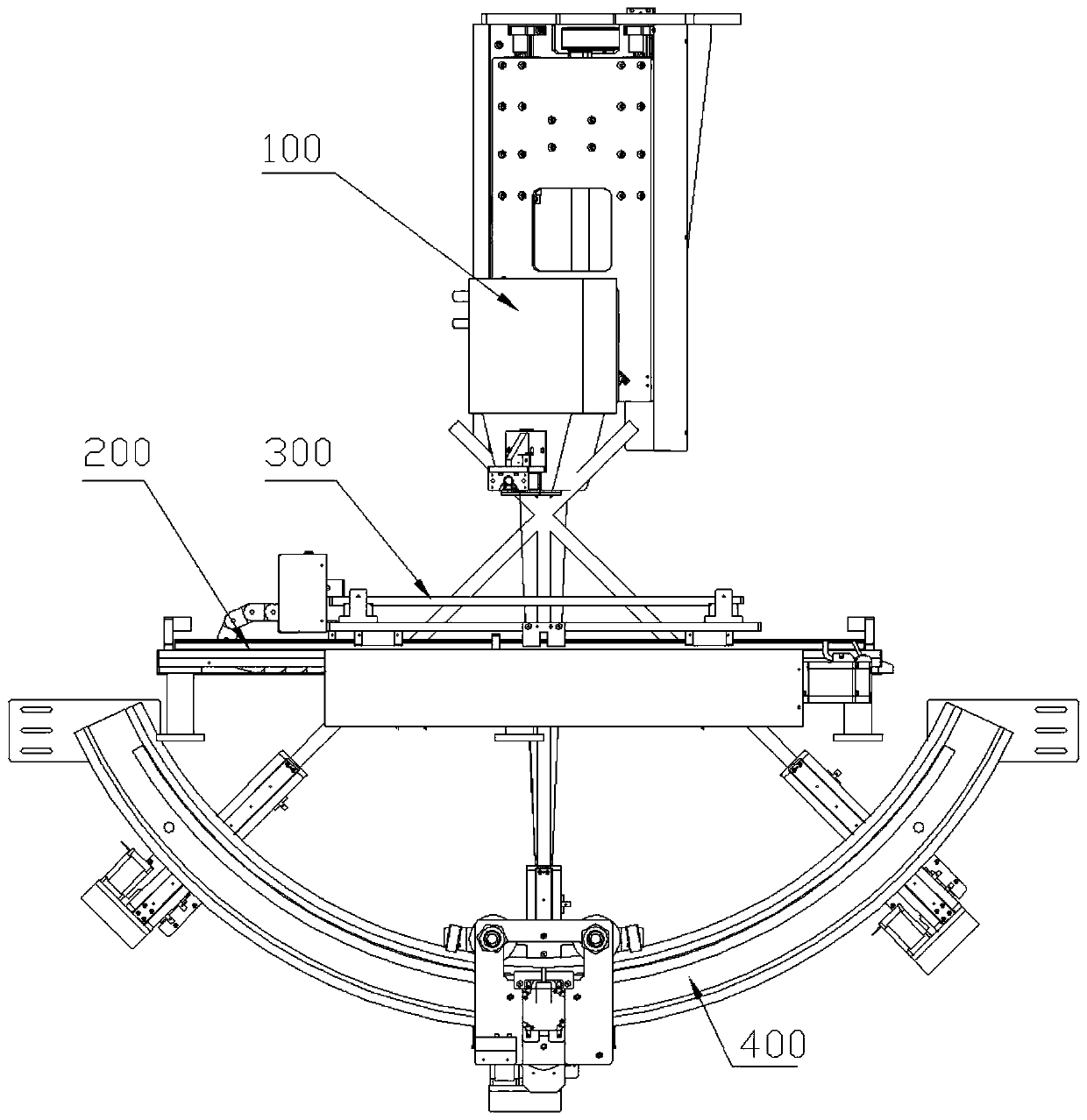

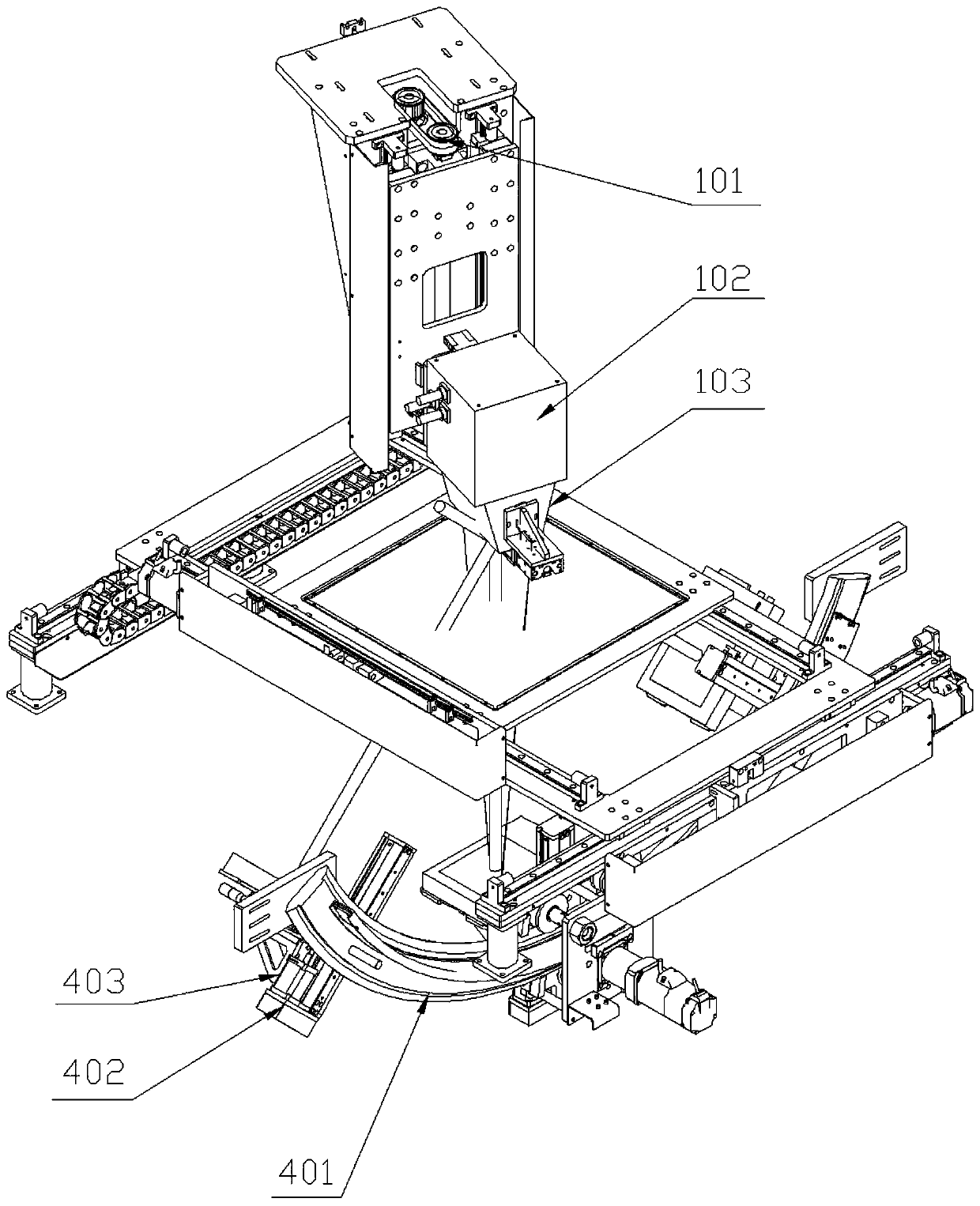

[0081] On the basis of Example 1, please refer to figure 2 and image 3 As shown, the online and offline integrated inspection machine provided in this embodiment can inspect products from multiple angles and realize rapid inspection and re-inspection functions.

[0082] Specifically, the detection device 400 includes:

[0083] Arc track assembly 401;

[0084] The first mounting base 402, the arc track assembly 401 is drivingly connected to the first mounting base 402, and is used to drive the first mounting base 402 to slide in an arc shape;

[0085] The first lifting drive assembly 403, the first lifting drive assembly 403 is installed on the first mounting base 402;

[0086] For the detector, the first lifting drive assembly 403 is connected to drive the detector, and is used to drive the detector to approach and move away from the product to be inspected.

[0087] Therefore, the detector is driven by the first lift driving assembly 403 to adjust the distance between t...

Embodiment 3

[0111] On the basis of Embodiment 1 and Embodiment 2, please refer to Figure 5 and Figure 6 As shown, this embodiment provides a detection method for an online and offline integrated detection machine, including the following steps:

[0112] S1. Select an online or offline mode, specifically dismantling or installing the installation frame 304;

[0113] S2. When it is in the online mode, the online transfer device 200 transfers the product to be inspected to the inspection station;

[0114] S3. When it is in the offline mode, put the product to be inspected into the offline inspection platform 300;

[0115] S4. The light source device 100 illuminates the product to be inspected;

[0116] S5. The detecting device 400 detects the product to be inspected;

[0117] S6. Judging whether the product to be inspected is qualified.

[0118] In the detection method provided in this embodiment, the detection mode can be selected as offline or online according to user needs. Specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com