A kind of spherical dielectric material and its production method and Lunberg lens

A technology of dielectric materials and production methods, applied in circuits, electrical components, antennas, etc., can solve problems such as easy separation of foamed materials and conductive fibers, low structural strength of dielectric materials, easy deformation of foamed materials, etc. The effect of light weight, low production cost, and accurate control of dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

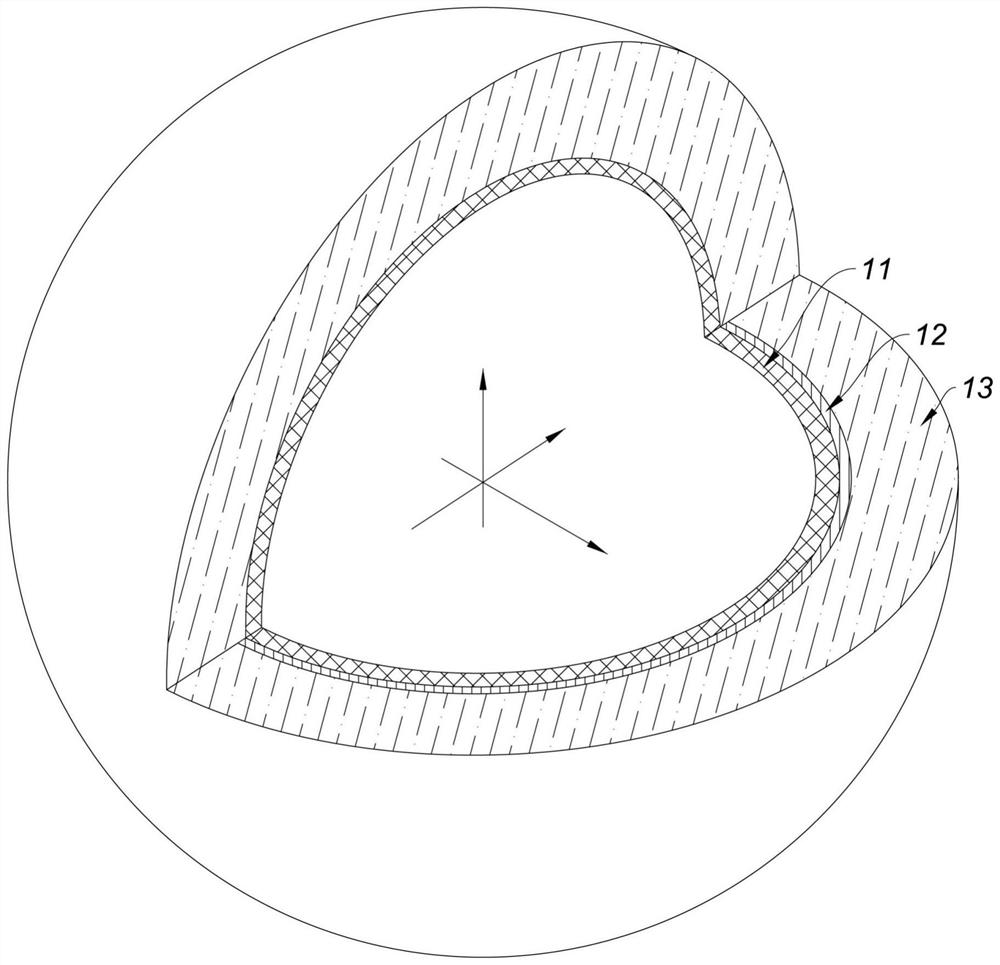

[0034] Such as figure 1 As shown, the present embodiment is a spherical dielectric material, which is a spherical structure, and the spherical structure includes an inner core 11, a conductive layer 12 and a foam material layer 13; the inner core 11 is made into a spherical shape, and the inner core The outer diameter of 11 is in the range of 3-6 mm, and the inner core 11 is made of non-metallic material; the conductive layer 12 is arranged on the surface of the inner core 11, and the area covered by the conductive layer 12 is equal to the inner core 11. Half of the outer surface area of the core 11, the thickness of the conductive layer 12 is in the range of 0.01 to 0.5 mm; the outer surface of the foam material layer 13 is a spherical structure, and the inner surface of the foam material layer 13 wraps the conductive layer. The outer surface of the layer 12 and the part on the surface of the inner core 11 not covered by the conductive layer 12, the thickness of the foam ma...

Embodiment 2

[0038] This embodiment is a production method of a spherical dielectric material, which is characterized in that it includes the following production steps:

[0039] 1) Use non-metallic materials to produce a spherical inner core. The inner core in step 1) is made into a hollow structure. The inner core is specifically made of plastic or glass, and the outer diameter of the inner core is between 3 and Within the range of 6mm;

[0040]2) Spray conductive material on the outer surface of the inner core by a spraying device to form a conductive layer on the inner core. The area covered by the conductive layer on the outer surface of the inner core is equal to half of the outer surface area of the inner core. The conductive layer in this step It is made into a hemispherical shape and the thickness of the conductive layer is in the range of 0.01-0.5mm; during production, the inner core is placed in the groove on the assembly line, and when the inner core on the assembly line walk...

Embodiment 3

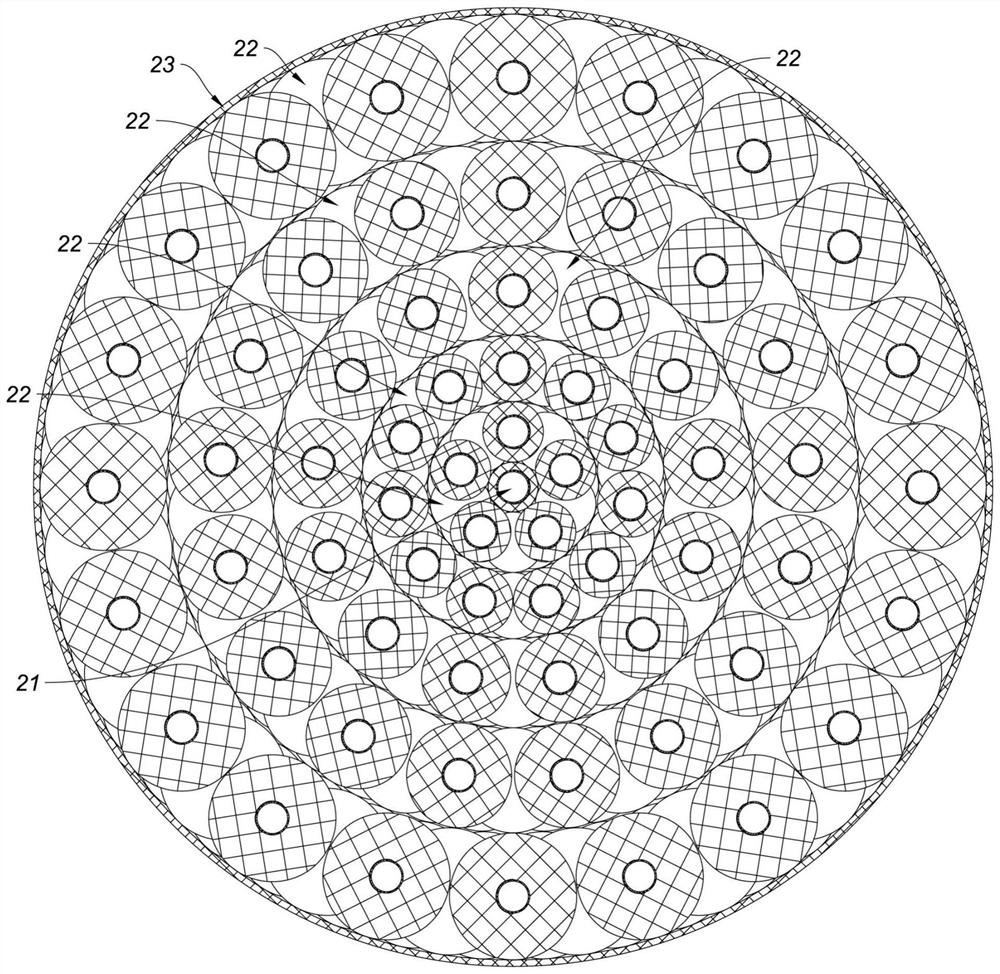

[0047] Such as figure 2 , image 3 As shown, the present embodiment is a Lunberg lens, comprising an inner core 21 and several dielectric layers 22 wrapping the inner core 21 layer by layer. In actual implementation, this Lunberg lens also includes a shell 23, an inner core 21 and a dielectric layer 22 It is in the shell 23; the inner core 21 is the spherical dielectric material described in Embodiment 1; each dielectric layer 22 is composed of several particle units respectively, and the particle units in each dielectric layer 22 are spherical dielectric materials described in Embodiment 1. Electrical material; the inner core 21 is connected with the dielectric layer 22 closest to the inner core 21 by glue, and the adjacent two dielectric layers 22 are also connected by glue; the inner core of the inner core 21 and each medium The inner core of the particle unit of layer 22 is identical, and the conductive layer of inner core 21 is identical with the conductive layer of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com