Patents

Literature

33results about How to "Light weight per unit volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant polysaccharide sponge body and its preparation method

InactiveCN1410452AExtensive sources of raw materialsLow cost of preparationPlasticizerMaterials science

A phytopolyose sponge is prepared from phytopolyose through adding filler, plasticizer, softening agent, foaming agent, water-proofing agent and antiseptic, high-temp. fusing-plasticizing and puffingin an extruder ,and shaping by die extruding.

Owner:姜发堂

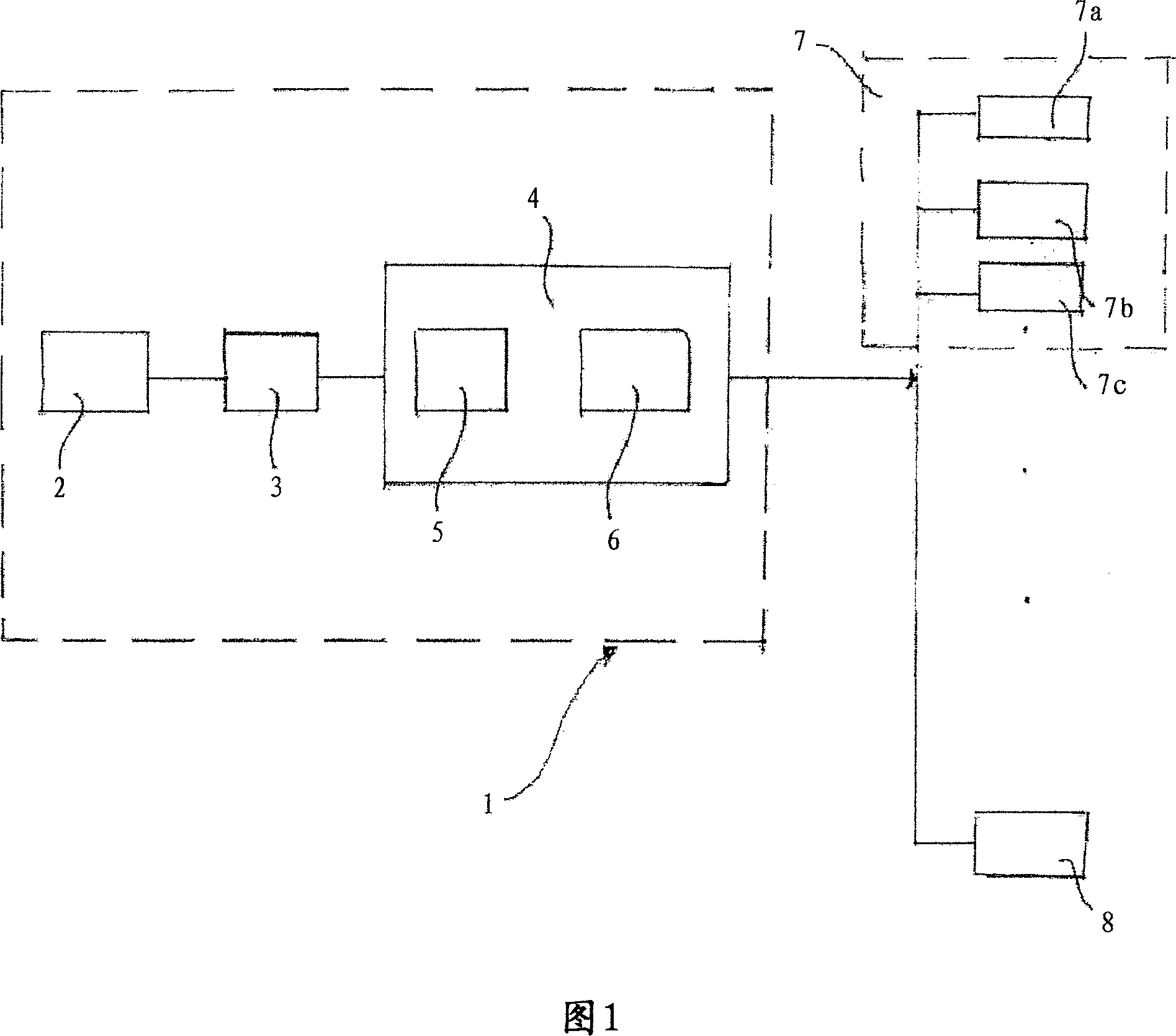

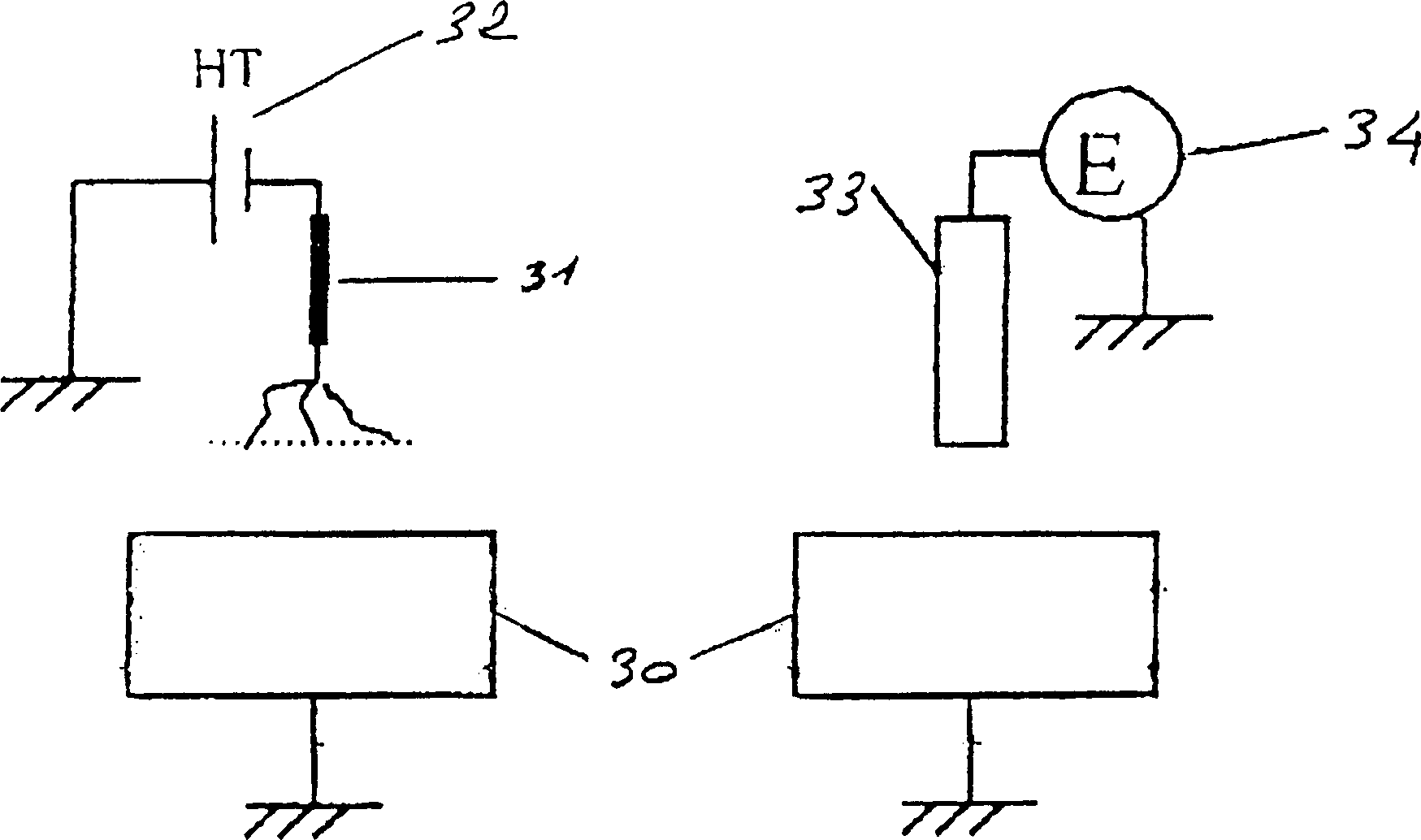

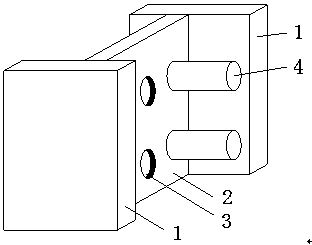

Compressed-air generating system

InactiveCN101014760AReduce weightThe principle is simplePower installationsEfficient propulsion technologiesSuperheated steamGas turbines

A system comprises an H2 / O2 steam generator (2) for generating superheated steam which is either fed directly to a gas turbine (8) to bring it to a rotary speed that is sufficient to result in a compressed-air ratio in the gas turbine that allows operation of the gas turbine with a fuel, or which superheated steam is fed to a compressed-air generator (4) for generating compressed-air, wherein the generated compressed-air is fed to a compressed-air system (7), for example of an aircraft, or is used for starting a gas turbine or for other compressed-air systems.

Owner:AIRBUS OPERATIONS GMBH

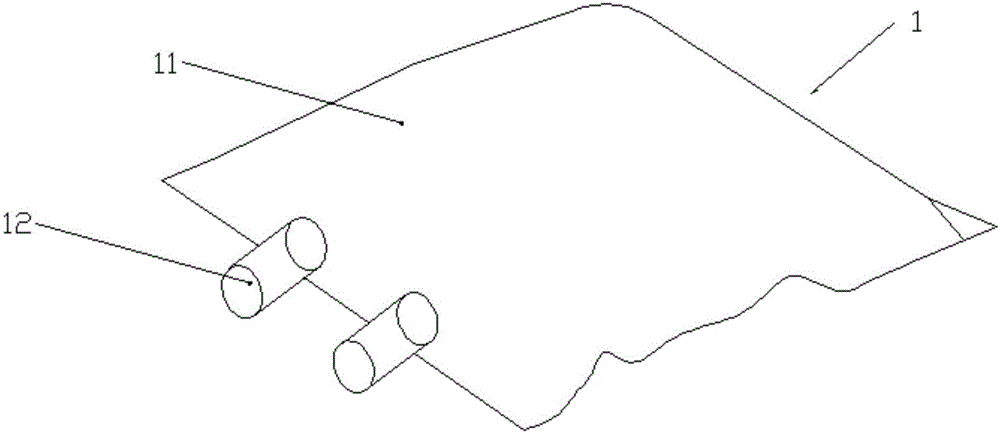

Grouting bag and application method

InactiveCN107524166AReduce construction costsAvoid local stress concentration problemsArtificial islandsUnderwater structuresShear forceStress concentration

The invention discloses a grouting bag and an application method. The grouting bag comprises an integrally-sealed bag body. The bag body is provided with at least one grouting port, and the bag body is made of elastic materials. When slurry capable of being cured is injected into the bag body, the bag body can be automatically expanded along with inflow of slurry. After grouting of the grouting bag, the space around the position where the grouting bag is located can be fully filled, the grouting bag is closely attached to the part between two steel shear keys through deformation of the grouting bag, and after the slurry is solidified, an anti-shear structure achieving shear force transmission through a cushion layer is formed between the two steel shear keys, good adaptability and high practicability are achieved in an immersed tunnel irregular anti-shear support system, and the problem of local stress concentration caused by other connecting manners can be effectively avoided; and meanwhile, the grouting bag can be used in the place with the narrow operation space, and due to the construction convenience of the grouting bag, the construction cost can be effectively reduced.

Owner:CCCC FOURTH HARBOR ENG CO LTD +3

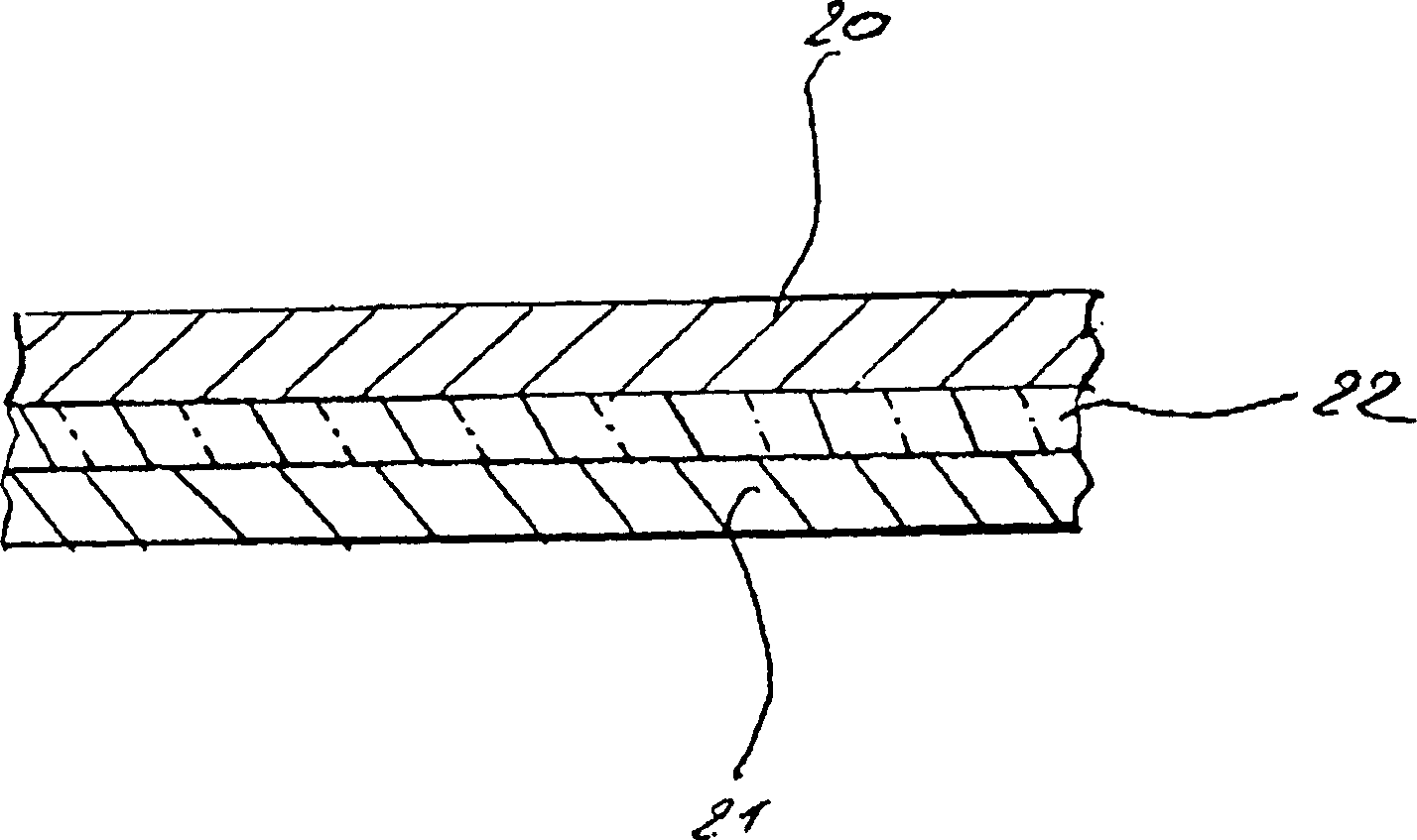

Non-woven fibric containing filament batt, manufacturing method and used as cleaning cloth

InactiveCN1396328AEasy to captureLight weight per unit volumeCarpet cleanersLayered productsEngineeringFilament yarn

Nonwoven which comprises at least one hydroentangled web of thermoplastic discontinuous fibres, hydroentangled with an unstretched batt of independent, inelastic, continuous filaments oriented at random.

Owner:赖特卜福叶特公司

Light ceramic materials and preparation process and use thereof

The invention relates to a lightweight ceramic material, which is prepared from magnesium soil and pore former through the steps of proportioning, ball grinding, squeezing, forming, drying and sintering. The material has the advantages of light weight, quench resistance, high intensity, strong corrosion stability, non-deformation, good heat-insulating property, and sound insulation performance.

Owner:萍乡市新安工业有限责任公司

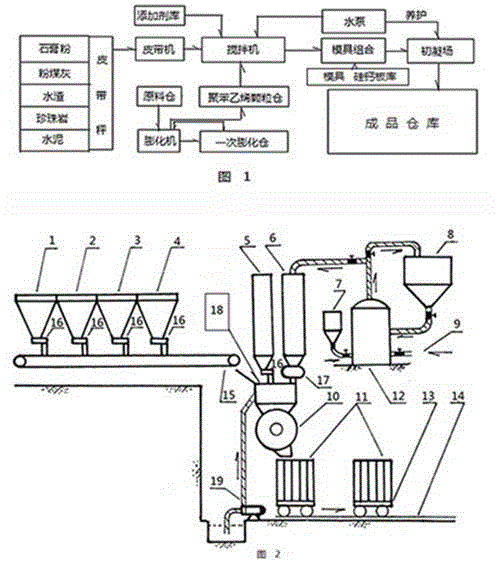

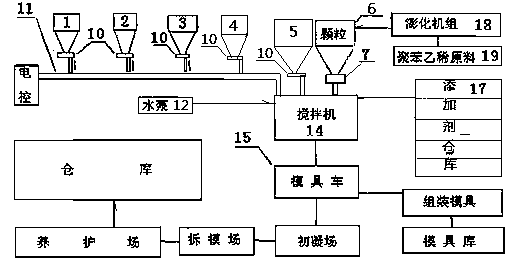

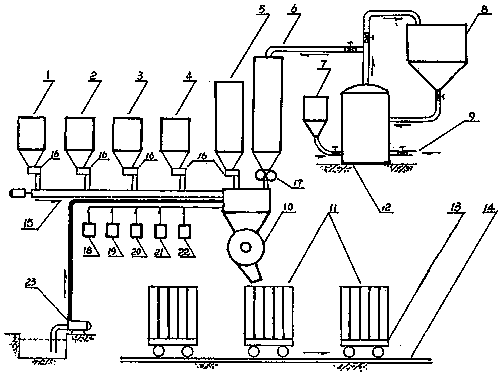

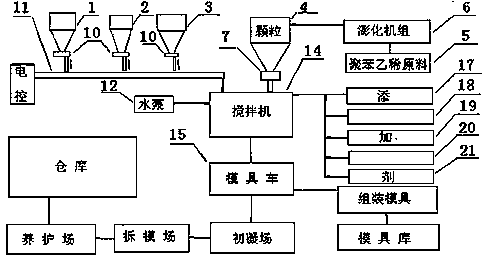

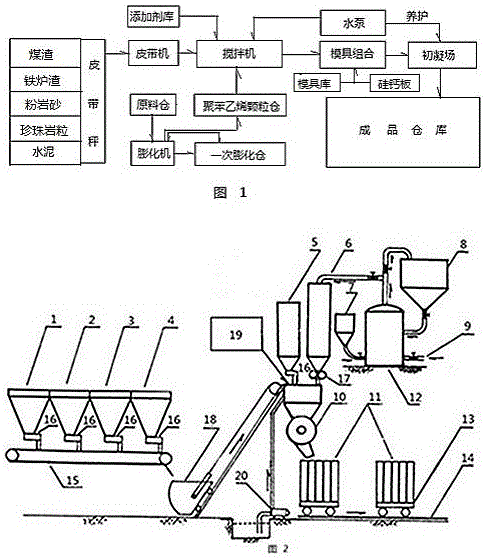

Coal cinder wallboard production method

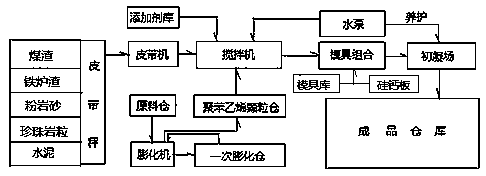

The invention discloses a coal cinder wallboard production method. Raw materials, such as gypsum powder, coal ash, water granulated slag, perlite and cement, are prepared into a dry mixture; each tonnage of the dry mixture is added with polystyrene particles, water and additives. A production system consists of hoppers, a cement stock bin, a polystyrene particle bin, a raw material bin, a one-time swelled feed bin, a steam pipe, a stirring machine, a die combination, a particle swelling machine, a die trolley, a light rail, a belt machine, belt weighers, a volume meter, an additive base and a water pump. The coal cinder wallboard production method is characterized in that a forklift loads materials into the hoppers; the belt weighers controlled by a computer and the stirring machine butted with a belt conveyer for realizing feeding are arranged at the outlets of the hoppers and the outlet of the cement stock bin; a polystyrene raw material enters the polystyrene particle bin after being subjected to secondary swelling and then is conveyed into the stirring machine through the volume meter; water is added into the water pump for stirring, and a water mixture is poured into a die for forming; the die trolley transports products into an initial setting and purifying area for artificial demolding after the setting period; the products are taken down from the die trolley for stacking and subjected to watering maintenance everyday; after the final setting period, the products are delivered and installed; the whole production process is conducted under normal temperature; the products are purely natural, green, healthy, ecological and environment-friendly wall materials.

Owner:LIXIAN FANGSHIPING TOWN YANGPU MINING MACHINERY FACTORY

Processing method of high-strength wood

ActiveCN108312271AHigh mechanical strengthSimple methodWood compressionWood treatment detailsWood machiningHigh intensity

The invention belongs to the technical field of material manufacture and particularly relates to a processing method of high-strength wood. The processing method comprises the following three main steps: firstly fixing 100-150 parts of dried wood in a reaction kettle, and treating by using a chemical method; then placing the wood in a hot-pressing machine, controlling the temperature to be 110-130DEG C and the pressure to be 6-9MPa and carrying out hot pressing for 12-18 hours; finally, after processing the wood into a needed shape, and carrying out preservative treatment. Compared with the prior art, the processing method of the high-strength wood has the advantages that the method is simple and is easy in implementation, the manufactured wood has very-high mechanical strength, is low indensity and light in mass per unit volume, and has very-good application prospect in all the fields such as aerospace.

Owner:婺源县新辉实业有限公司

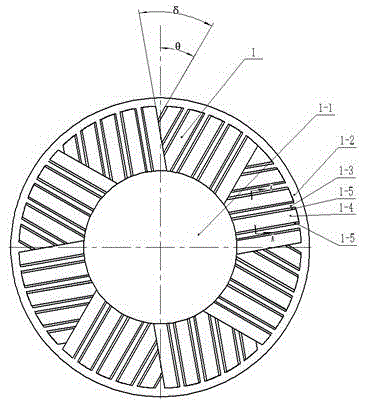

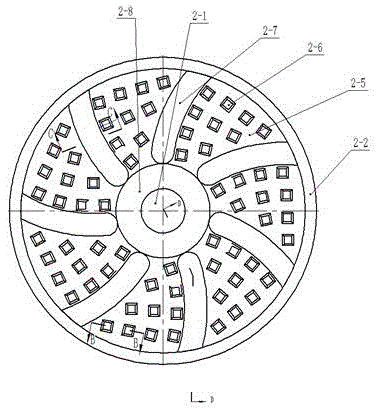

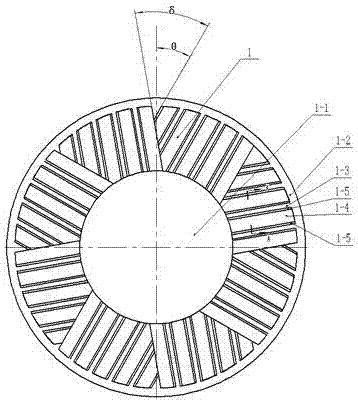

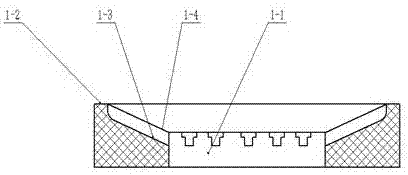

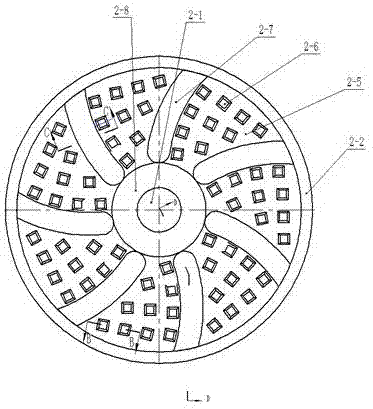

Ceramic grinding disc for food grinding processing

ActiveCN105536929ASolve the strength problemSolve wear resistanceCocoaGrain treatmentsUltimate tensile strengthGRINDING TOOTH

A ceramic grinding disc for food grinding processing solves the problems that for an existing grinding disc, foodstuff distribution is nonuniform, the diversion speed is low, discharging is difficult, feeding blocking is prone to be caused, and the grinding efficiency is low. The ceramic grinding disc is characterized in that the internally-concave conical surface of a fixed grinding disc body is provided with symmetrical step-shaped oblique teeth, and the internally-concave plane of a movable grinding disc body is provided with material guide grooves and trapezoid teeth; according to the movable grinding disc body, multiple trapezoid teeth which are independent and are mutually staggered form a grinding tooth array, and according to the fixed grinding disc body, multiple independent symmetrical step-shaped oblique teeth form the internally-concave conical grinding surface. The ceramic grinding disc for food grinding processing has the advantages that foodstuffs conduct dynamic collision with the movable grinding disc body and the fixed grinding disc body in an internally-concave conical grinding cavity between the movable grinding disc body and the fixed grinding disc body, the flowing velocity of the foodstuffs is increased under the synergistic action of extruding, breaking, shearing and grinding, secondary grinding is conducted through the two peripheral grinding surfaces of the movable grinding disc body and the fixed grinding disc body, the ground foodstuffs are filtered and flow out of grinding and screening gaps, the grinding efficiency and the grinding effect are improved, and the grinding disc is high in strength, good in wear-resisting property, long in service life and suitable for industrialized continuous production.

Owner:LIAONING YINGGUAN HIGH TECH CERAMIC CO LTD

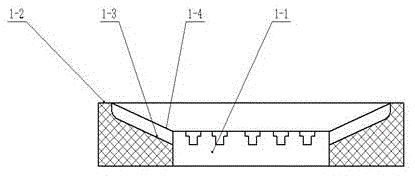

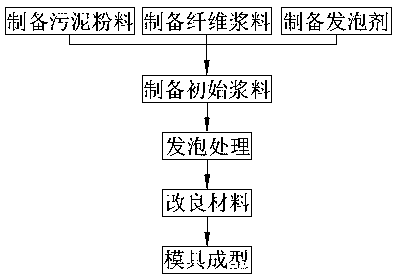

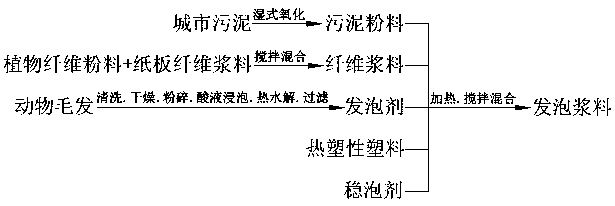

Composite packaging material prepared by utilizing municipal sludge and preparation method thereof

The invention relates to the field of environmental protection treatment of sludge, and in particular to a composite packaging material prepared by utilizing municipal sludge and a preparation methodthereof. The composite packaging material contains foamed slurry obtained by mixing and stirring sludge powder, fiber slurry and a foaming agent, wherein the sludge powder is obtained by carrying outphysicochemical treatment for decomposing organic matters on the municipal sludge; and the content of the organic matters in the sludge powder is less than 10%. By fully utilizing cellulose, silicon oxide and various metal oxides in the municipal sludge subjected to the physicochemical treatment for decomposing the organic matters, the obtained composite packaging material has better fire and insect bite preventing properties relative to an ordinary packaging paperboard; microorganisms and the organic matters in the material are decomposed and bacterial virus is eliminated to ensure that the material is not easily affected by external acid and alkali environments and is stable in performance and wide in application range; and the foaming agent is added and the number of bubbles in the obtained material is increased to ensure that the material has better heat insulation effect, high and low temperature resistance and moisture resistance and is wider in the application range.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

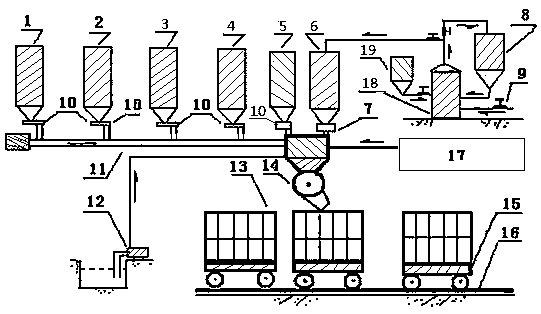

Production technology for partition bricks

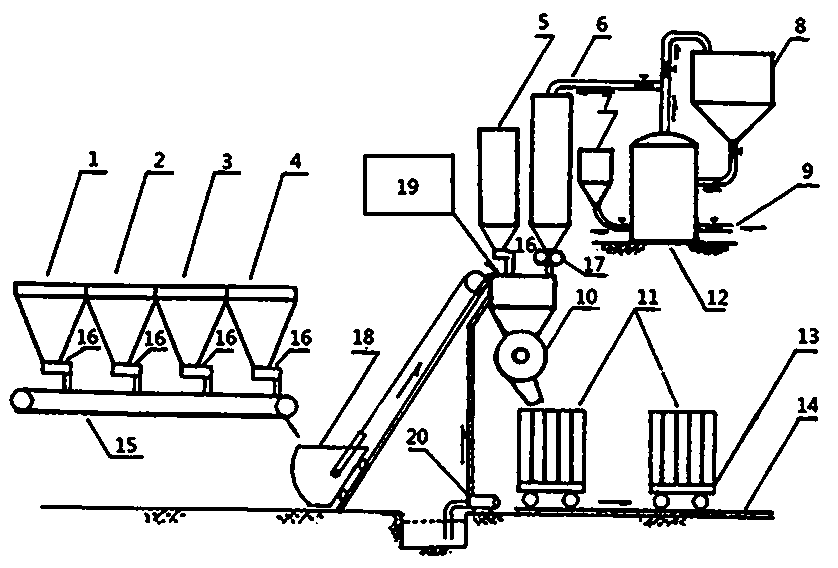

According to a production technology for partition bricks, various raw material bins, a polystyrene particle bin, a polystyrene raw material bin, a bulking machine, a volume measuring device, a primary bulking bin, electronic balances, a screw conveyor, a water pump, a mold combination, a stirring machine, a mold vehicle and an additive warehouse are included. The technology is characterized in that the electronic balances are mounted at outlets of the various raw material bins to be butt-jointed with the screw conveyor, and an outlet of the screw conveyor is connected with the stirring machine; addition of polystyrene particles is controlled by the volume measuring device, water is added, various additives are added manually, stirring is performed, and the water mixture is poured into themold combination to be molded; solidification is started after the water mixture is poured into the mold combination and left to stand; a formula is as follows: lime residues, boiling slag, lime powder, fine sand and cement form a dry mixture; each ton of the dry mixture is mixed with the polystyrene particles, the water and the additives to form a wet mixture; the lime residues and the boiling slag are used as aggregate, and the aggregate has the certain strength after being solidified; manual demolding is performed after bricks are transported by the mold vehicle after mold filling to the standing field for 24 h, the bricks are stacked, water is applied for maintenance, the bricks are stored after the final setting period, and the bricks are purely nature, green, healthy, ecological andenvironment-friendly wall materials.

Owner:杨朴

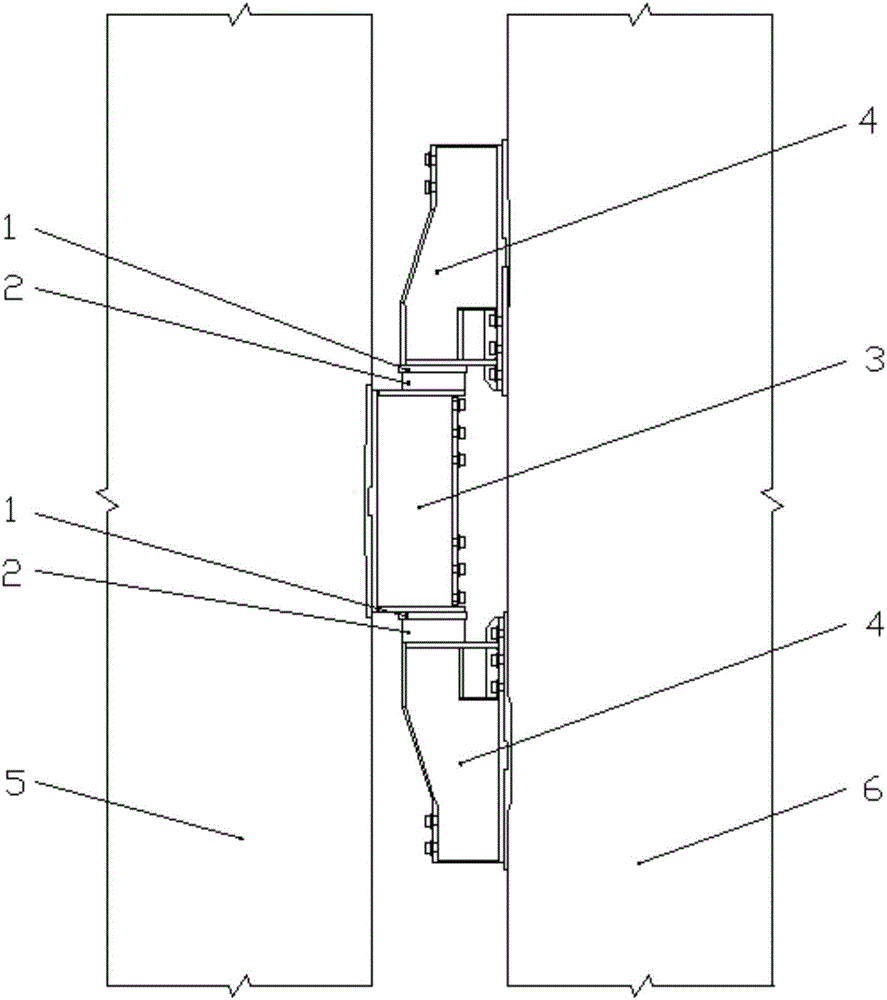

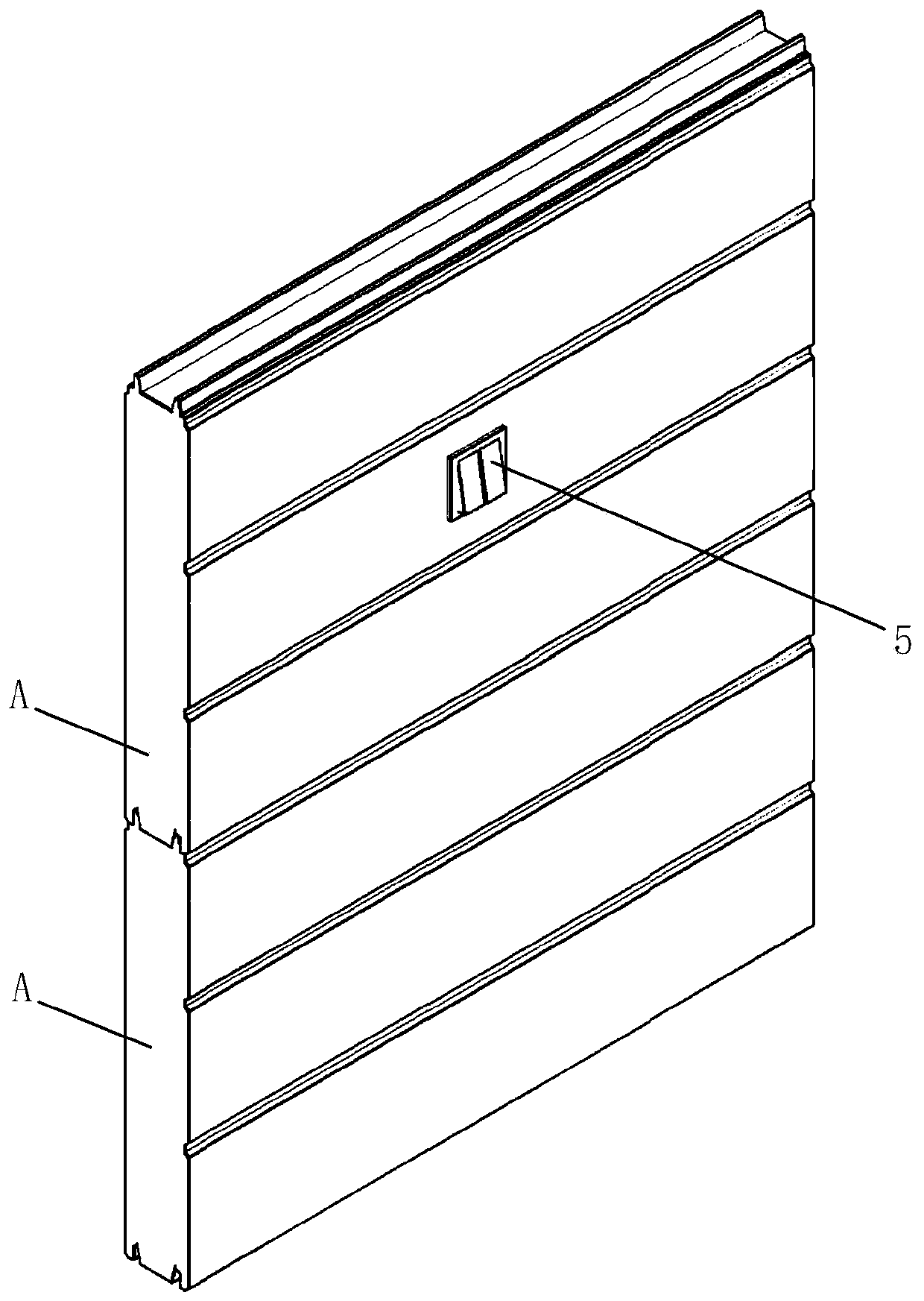

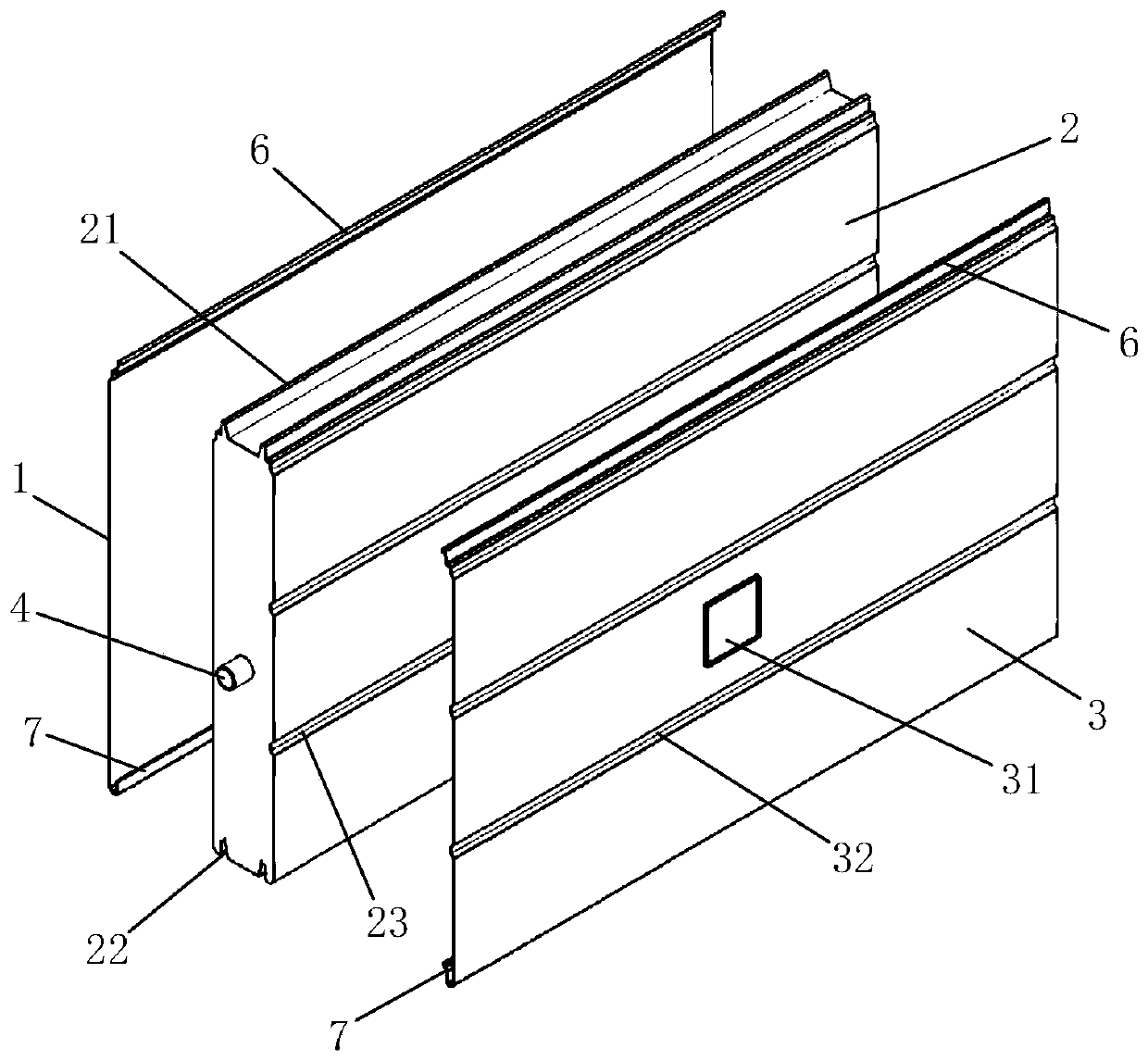

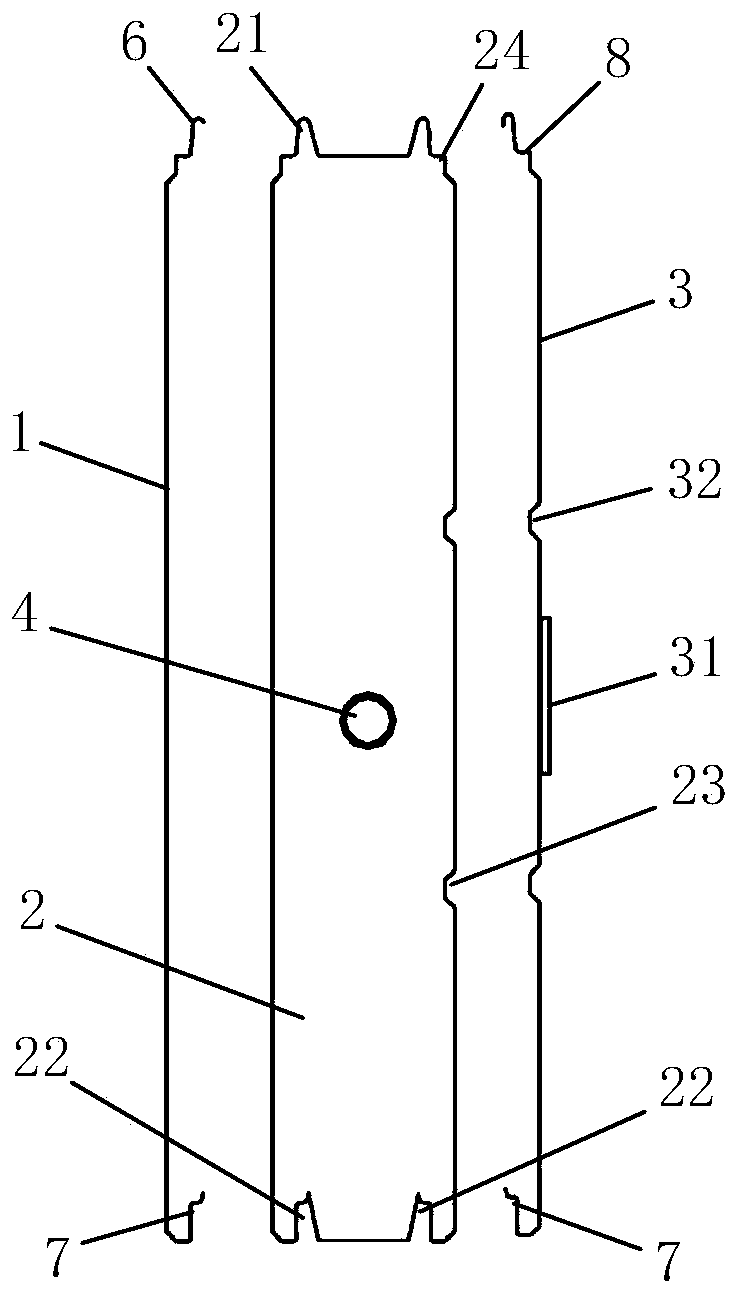

Modularized wallboard structure

PendingCN109826361ABeautiful appearanceSimple production processBuilding componentsElectrical wiringAluminium alloy

The invention discloses a modularized wallboard structure. The modularized wallboard structure is formed by a plurality of wallboard unit modules which are in inserted connection in sequence; each wallboard unit module includes a polyurethane and ceramsite mixed foaming body, a first contour plate and a second contour plate, and the first contour plate and the second contour plate are fastened tothe surfaces of the two sides of the polyurethane and ceramsite mixed foaming body; a switch / socket box is at least arranged inside the second contour plate, and water-electricity mounting pipes are pre-arranged in the polyurethane and ceramsite mixed foaming body. The modularized wallboard structure is formed by combining the polyurethane and ceramsite mixed foaming body and the aluminium alloy contour plates, the appearance is attractive, and the production technology is simple; a concave-convex structure is adopted to conduct butt jointing, so that the modularized wallboard structure is convenient to mount; water-electricity wires and pipes and strong and weak electricity wires are pre-embedded in a wall body, and thus construction in a later period is convenient; a product has the advantages of being low in cost, long in service life, high in strength, good in heat and sound insulation effect, low in bulk density and the like; the modules are in direct inserted connection with oneanother, joints are tightly connected, and thus seamless butt jointing is achieved.

Owner:曹友国

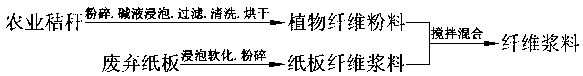

Application method of plant fibers in mesh gypsum board

InactiveCN110357554AImproves Strength and ToughnessLight weight per unit volumeSolid waste managementCeramicwareGypsumContinuous production

An application method of plant fibers in a mesh gypsum board belongs to the field of waste resource utilization. The method comprises the following steps: 1, removing impurities from plant wastes, andcrushing the plant wastes; 2, desugaring and deacidifying the crushed plant wastes; 3, mixing and stirring the treated plant wastes obtained in step 2 and a gypsum slurry; 4, adding the mixed and stirred gypsum slurry into a slurry stirring device in a continuous production line for the gypsum board; 5, lacing a mesh fabric coil on a paper roll mounting device of the continuous production line for the gypsum board; 6, turning on the continuous production line for the gypsum board; and 7, cutting the gypsum board with a continuous length according to use requirements. The method has the characteristics of improvement of the performances of the gypsum board, comprehensiveness in utilization of wastes, and reduction of environmental pollution.

Owner:ZHENGZHOU SUNDY BUILDING TECH

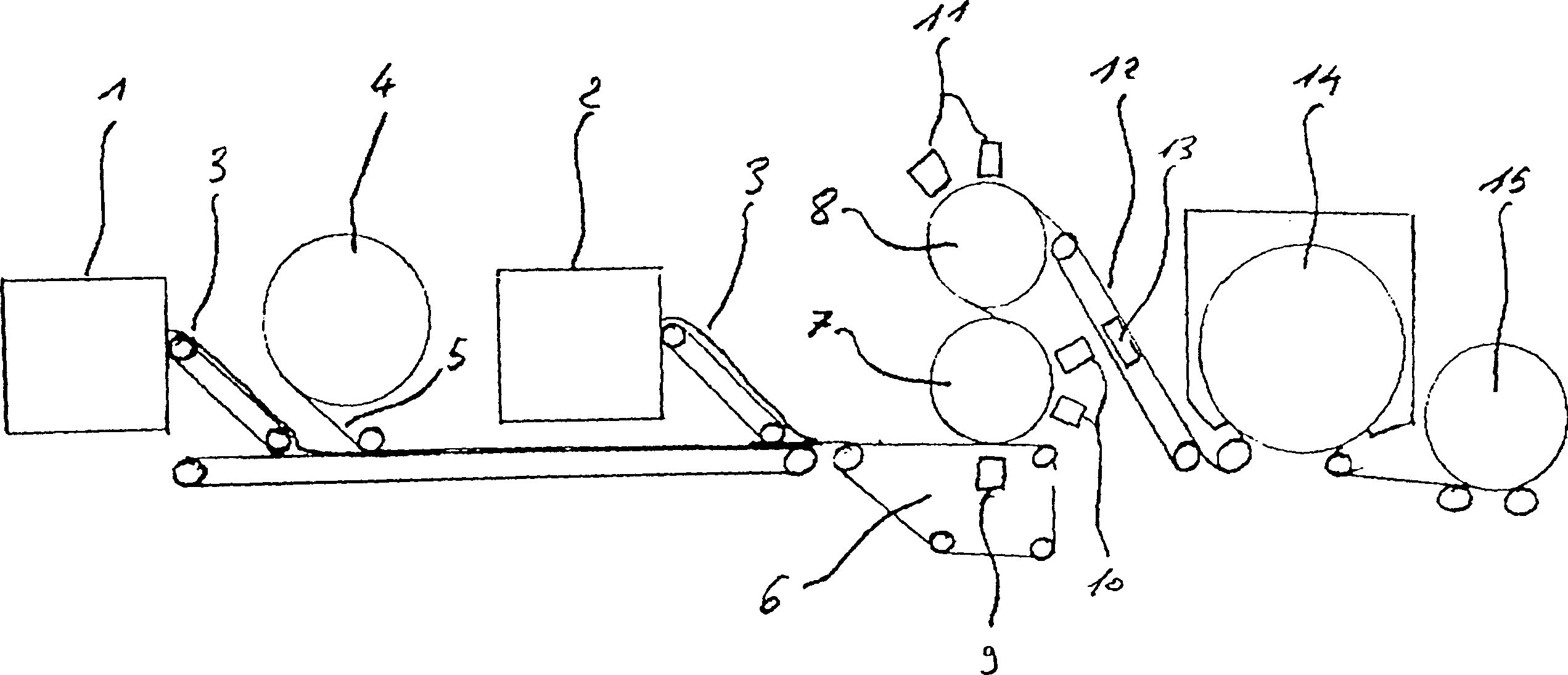

Wallboard production method

InactiveCN107891518ALight weight per unit volumeImprove water resistanceCeramic shaping plantsFeeding arrangmentsSlagButt joint

A wallboard production system comprises stone coal cinder, fly ash, grain slag, yellow sand, a cement bin, a polystyrene particle bin, an expansion bin, a stirring machine, mold sets, an expansion machine, a mold trolley, a light rail, an auger, an electronic scale, a light material counter, additives and a water pump. The wallboard production method is characterized in that outlets of the bins are provided with the electronic scale in butt joint with the auger; the auger is connected with the feeding end of the stirring machine; the stirring machine is connected with the polystyrene particlebin and a water pipe; the mold trolley is arranged on the light rail; and the 30 mold sets are arranged on the mold trolley and are in butt joint with an outlet of the stirring machine. According to the formula, dry blend is formed by the stone coal cinder, the fly ash, the grain slag, the yellow sand and cement, polystyrene particles, water and the additives are added into per ton of dry blend, the grain slag and the stone coal cinder are crushed into aggregate, stirred for 10 min and put into molds to be molded, solidification is conducted through a standby field, water is applied every day,and wallboards are put into storage 30 days later. An interval production mode is adopted, and the products are non-toxic, odorless and free of radioactive contamination and are natural, green, healthy and ecologically-friendly wall materials.

Owner:杨朴

Light brick production method

InactiveCN107891519AEasy to buryImprove machinabilityCeramic shaping plantsBrickEcological environment

The invention discloses a light brick production method. The light brick production method adopts a stone coal cinder bin, a furnace slag bin, a cement bin, a polystyrene particle bin, a raw materialbin, a bulking machine, a volume meter, a primary bulking bin, electronic scales, a packing auger, a water pump, a mould assembly, a stirrer, a mould car and an additive bin, wherein the outlet of each bin is equipped with the electronic scale, is in butt joint with the packing auger, and is connected with the stirrer; the volume meter controls adding of polystyrene particles and water, and various additives are manually added and stirred for 10 minutes; a water mixture is injected into the mould assembly to form; and solidification is started after cast pouring and standing; a formula comprises stone coal cinders, furnace clinker and cement which form dry blend; each ton of dry blend is added with the polystyrene particles, the water and the additives to form wet blend; the stone coal cinders and the furnace slag are taken as aggregates, and are solidified to form certain strength; and the mould car subjected to cast pouring is manually de-molded 24 hours after being transported to aninitial setting and standing area, is stacked, is applied with water to maintain, and leaves a factory after a final setting period. The light brick is a pure natural, green, healthy and ecological environment-friendly wall material.

Owner:杨朴

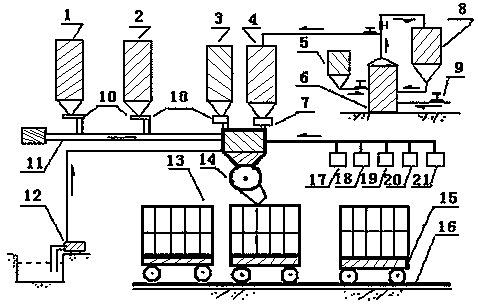

Production method of cinder sandwich type wall panel

InactiveCN105922448ASmall footprintIncrease the usable areaDischarging apparatusFeeding arrangmentsCinderPerlite

The invention provides a production method of a cinder sandwich type wall panel. Materials comprise cinder ash, iron-ore slag, siltstone sand, perlite particles and cement which constitute a dry blend; polystyrene particles, water and various additives are added into the dry blend, and the additives comprise methylcellulose, latex powder, an early strength agent, a water reducer and an air entraining agent; a production system comprises a cinder hopper, an iron-ore slag hopper, a siltstone sand hopper, a perlite particles hopper, a cement bin, a polystyrene particles bin, a raw material bin, a primary expansion bin, a steam pipe, a blender, assembling dies, an expansion unit, die cars, a light rail, a belt conveyor, an electronic scale, a counter, a skip, an additive library and a water pump. The production method is characterized in that a computer controls the electronic scale to weigh the materials of all the hoppers according to the quantities required by 30 plates, fed to the belt conveyor, added to the lifting skip and conveyed to the blender; the polystyrene raw material is subjected to twice expansion, then enters the polystyrene particles bin, and is added into the blender by the volume counter; water and the additives are added, and then stirring is fully performed; the water blend is poured into the prepared assembling dies for molding; and the production method can change waste into treasure, and the cinder sandwich type wall panel produced by the production method is a purely natural, green, healthy, ecological and environment-friendly wall material.

Owner:LIXIAN FANGSHIPING TOWN YANGPU MINING MACHINERY FACTORY

Light ceramic material and its manufacturing method and use

InactiveCN1182076CEasy to manufactureLight weight per unit volumeCeramicwareAdhesiveFilling materials

The formula of light ceramic material used in chemically filling material, catalyst carrier, filtering equipment, heat-insulating equipment, sound-insulating equipment and radiation equipment includes magnesium clay, piaozhu, pearlite powder, pore-forming agent and adhesive, and its preparation process includes the steps of mixing, materials ball-grinding, press-drying, forming stove-drying and sintering to obtain the invented product which can be substituted for ceramic, wood, metal and plastic products.

Owner:李金山

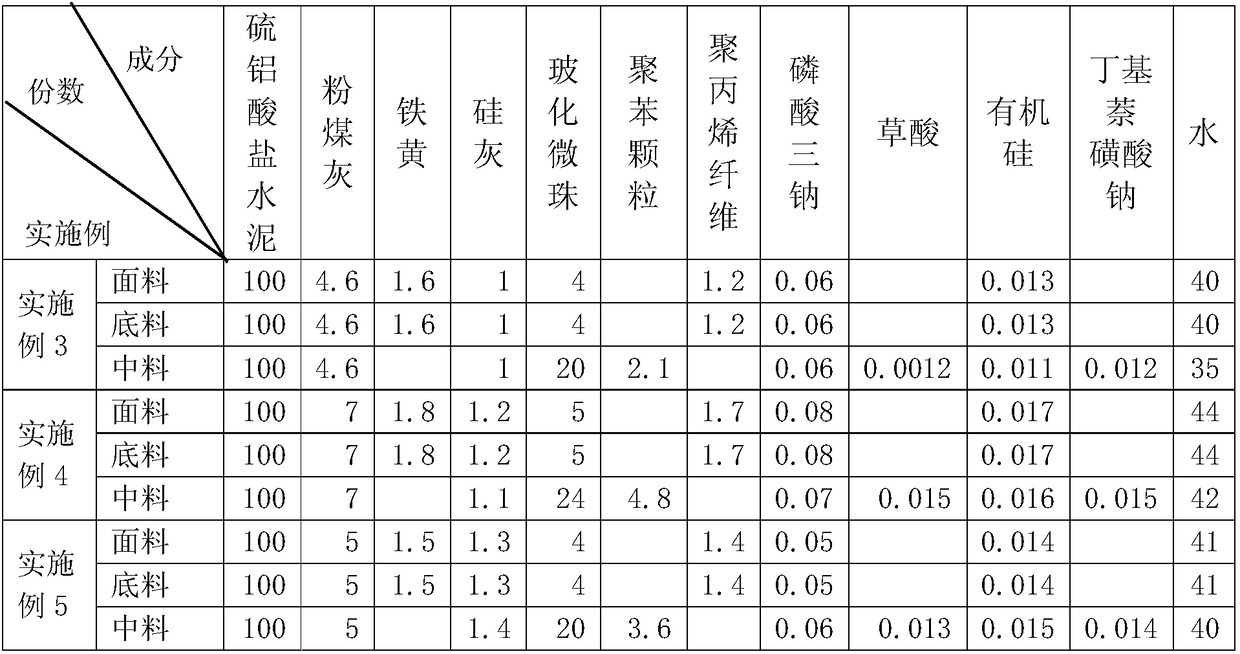

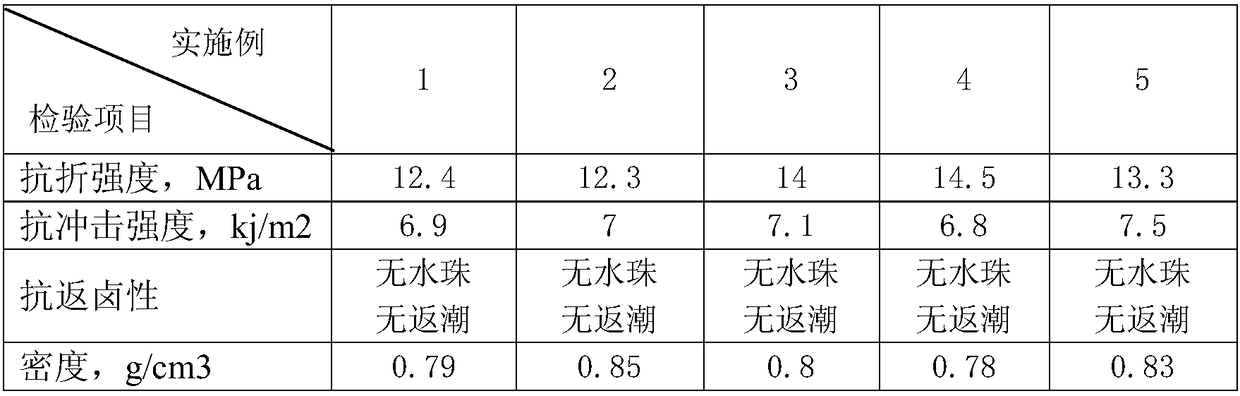

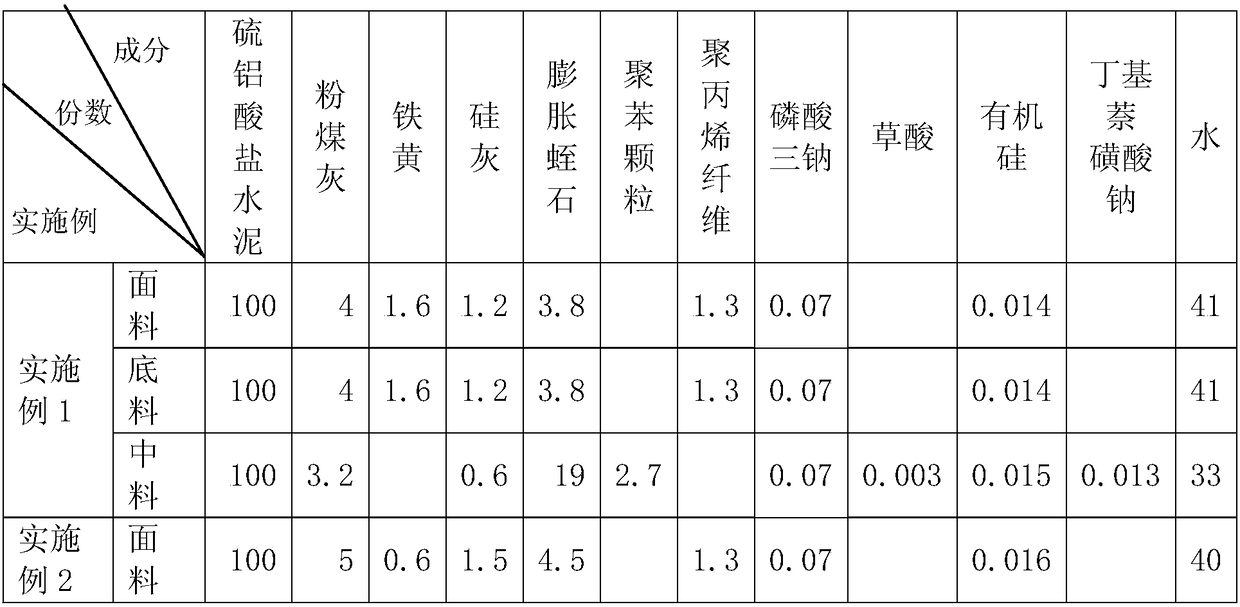

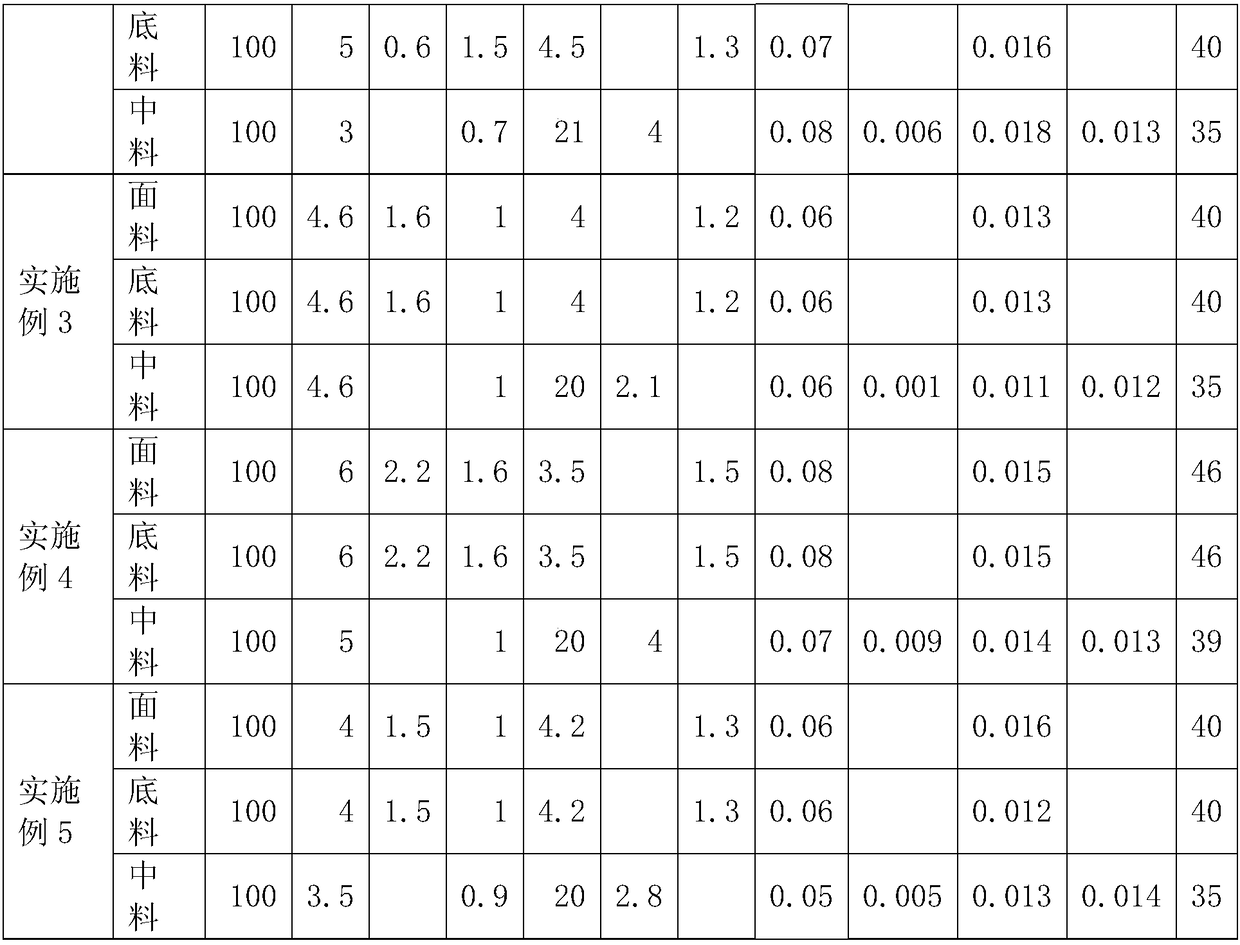

A vitreous microbead lightweight thermal insulation wall block

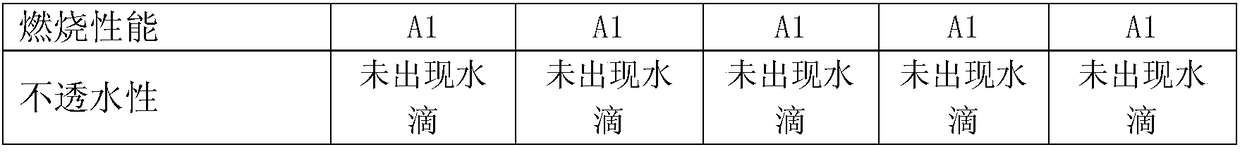

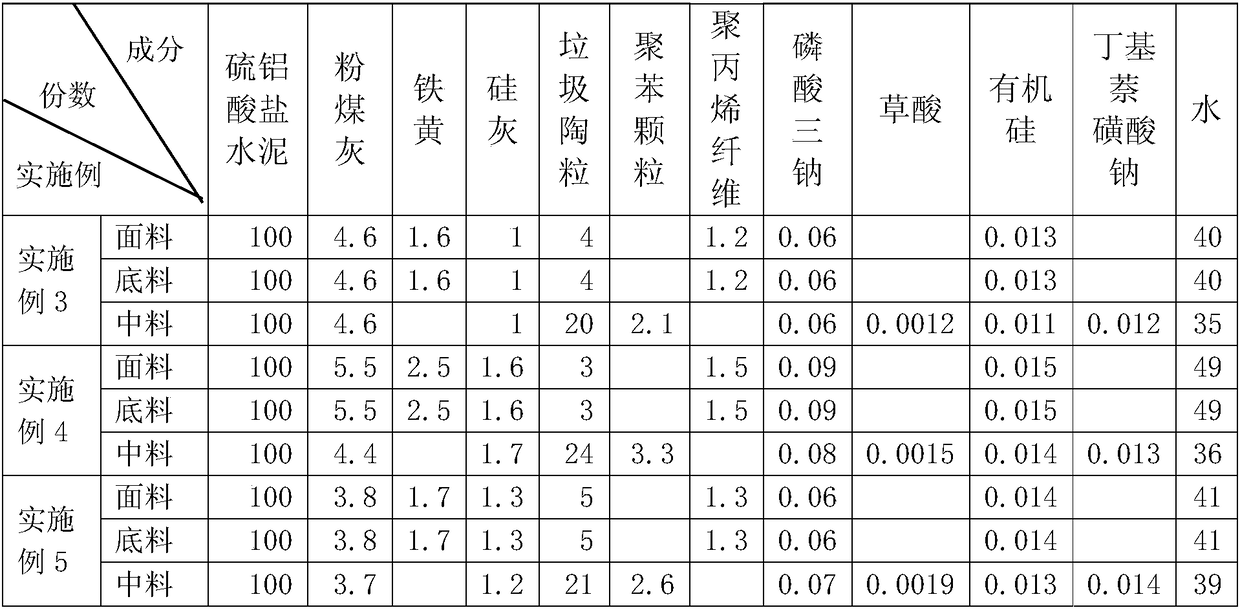

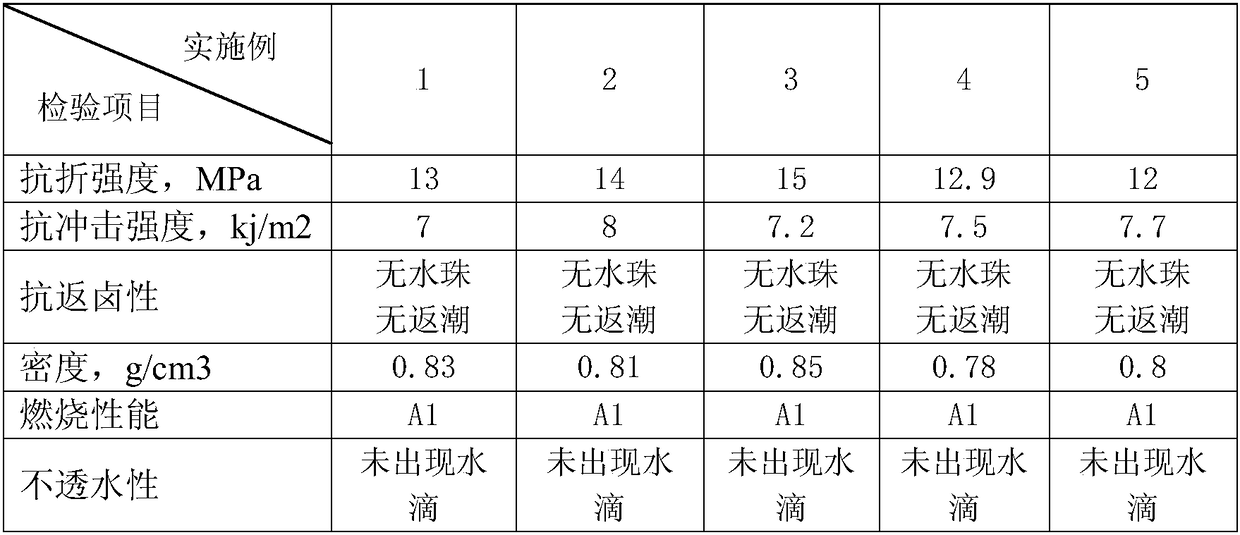

The invention provides a vitreous microbead lightweight thermal insulation wall block. The vitreous microbead lightweight insulation wall block includes bed material, medium material, surface materialand a gridding cloth, the fabric and the bed material are composed of the following components, by weight: 100 parts of sulphoaluminate cement, 2-8 parts of fly ash, 0.5-3 parts of iron oxide yellow,0.5-2 parts of silica fume, 2-6 parts of a vitreous microbead, 1-2 parts of mekralon, 0.05-0.1 part of trisodium phosphate, 0.01-0.02 part of organosilicon, and 35-50 parts of water; the medium material is composed of the following components, by weight: 100 parts of the sulphoaluminate cement, 2-8 parts of the fly ash, 0.5-2 parts of the silica fume, 15-25 parts of the vitreous microbead, 1-5 parts of a polystyrene granule, 0.05-0.1 part of the trisodium phosphate, 0.001-0.01 part of oxalic acid, 0.01-0.02 part of organosilicon, 0.01-0.015 part of sodium butylnaphthalenesulfonate, and 30-40parts of the water. The wall block has the advantages of low cost, high strength, long service life, excellent insulation and sound insulation effect, and light weight.

Owner:卓达新材料科技集团潍坊有限公司

A garbage ceramsite lightweight thermal insulation wall block

PendingCN108821707ALow costHigh strengthBuilding componentsThermal insulationExpanded clay aggregate

A provided garbage ceramsite lightweight thermal insulation wall block includes bed material, medium material, surface material and a grid cloth, the fabric and the bed material are prepared from thefollowing components, by weight: 100 parts of sulphoaluminate cement, 2-8 parts of fly ash, 0.5-3 parts of iron oxide yellow, 0.5-2 parts of silica fume, 2-6 parts of garbage ceramsite, 1-2 parts of mekralon, 0.05-0.1 part of trisodium phosphate, 0.01-0.02 part of organosilicon and 35-50 parts of water; the medium material is prepared from the following components, by weight: 100 parts of the sulphoaluminate cement, 2-8 parts of the fly ash, 0.5-2 parts of the silica fume, 15-25 parts of the garbage ceramsite, 1-5 parts of a polystyrene granule, 0.05-0.1 part of the trisodium phosphate, 0.001-0.01 part of oxalic acid, 0.01-0.02 part of the organosilicon, 0.01-0.015 part of sodium butylnaphthalenesulfonate, and 30-40 parts of the water. The wall block has the advantages of low cost, high strength, long service life, excellent insulation and sound insulation effect, and light weight.

Owner:卓达新材料科技集团潍坊有限公司

A kind of processing method of high-strength wood

ActiveCN108312271BHigh mechanical strengthSimple methodWood compressionWood treatment detailsIndustrial engineeringWood processing

The invention belongs to the technical field of material manufacture and particularly relates to a processing method of high-strength wood. The processing method comprises the following three main steps: firstly fixing 100-150 parts of dried wood in a reaction kettle, and treating by using a chemical method; then placing the wood in a hot-pressing machine, controlling the temperature to be 110-130DEG C and the pressure to be 6-9MPa and carrying out hot pressing for 12-18 hours; finally, after processing the wood into a needed shape, and carrying out preservative treatment. Compared with the prior art, the processing method of the high-strength wood has the advantages that the method is simple and is easy in implementation, the manufactured wood has very-high mechanical strength, is low indensity and light in mass per unit volume, and has very-good application prospect in all the fields such as aerospace.

Owner:婺源县新辉实业有限公司

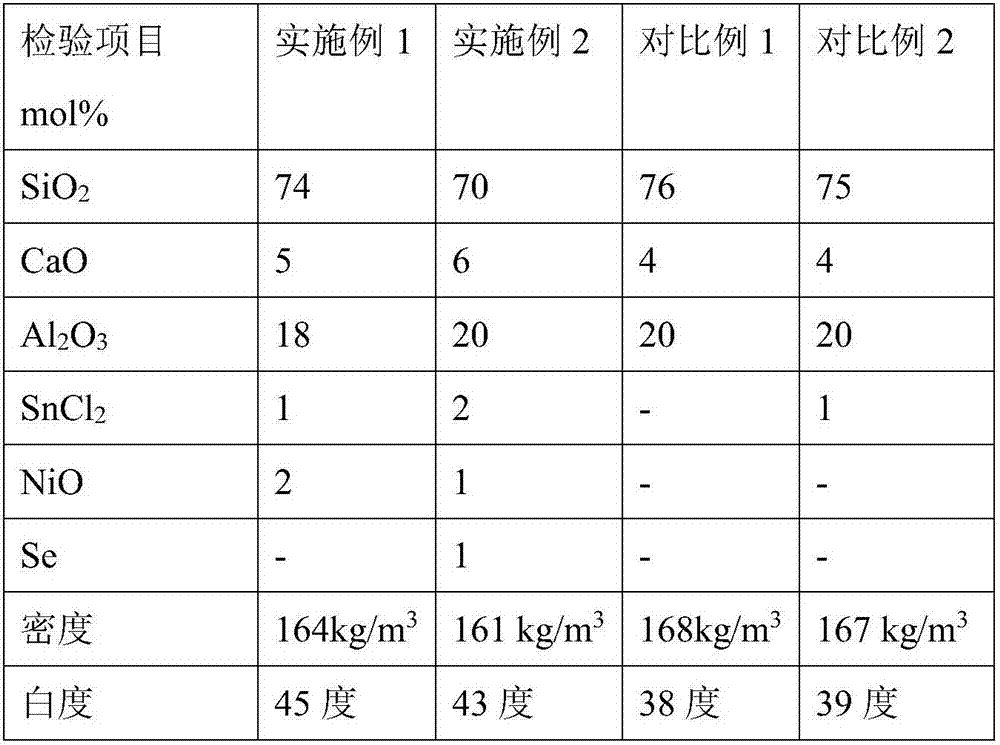

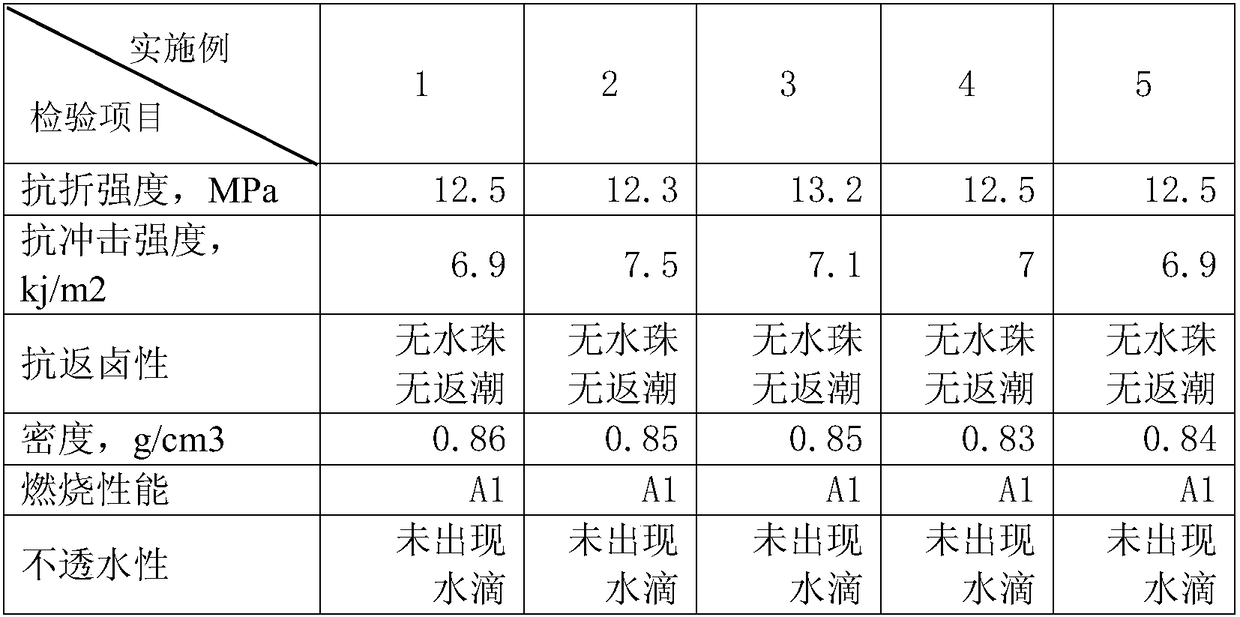

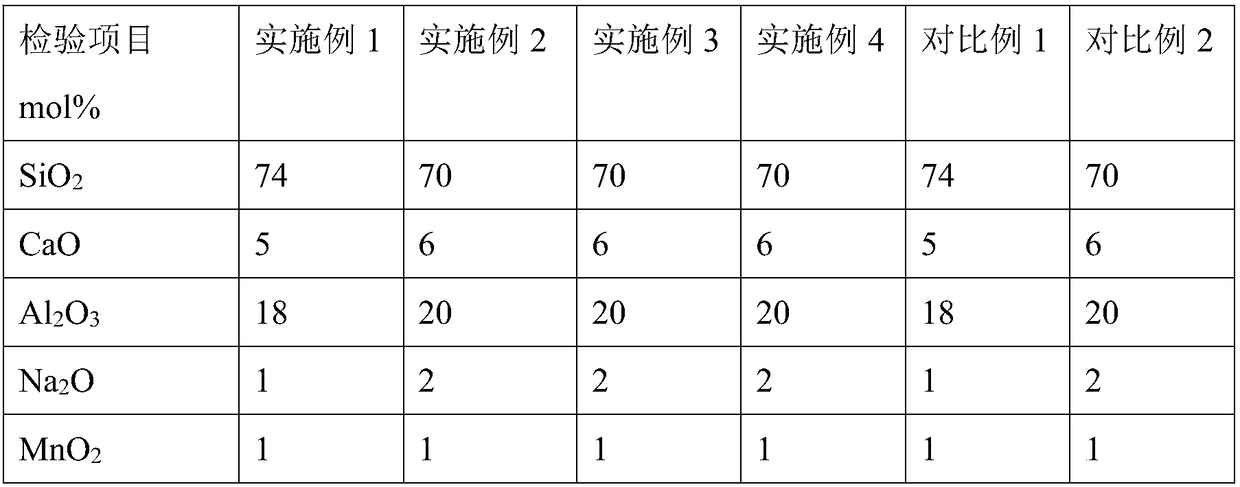

White foam glass

InactiveCN107382076AHigh whitenessLow densityGlass shaping apparatusThermal insulationPipe insulation

The invention relates to white foam glass. The glass comprises essential components and at least one decoloring component, wherein the essential components comprise about 70-76 mol% of SiO2, about 5-9 mol% of CaO, 18 mol% to about 22 mol% of Al2O3, and about 1-2 mol% of SnCl2, and the at least one decoloring component comprises (a) NiO which is greater than 0 mol% to about 5 mol%, and / or (b) Se which is greater than 0 mol% to about 4 mol%. The white foam glass has the characteristics of being high-whiteness in appearance, low in building cost, long in service life, good in effects of heat insulation and sound insulation, light in bulk unit weight and the like, and the density is 165 kg / m<3> or below.

Owner:HEBEI ZHUODA BUILDING MATERIALS RES INST CO LTD

An expanded vermiculite lightweight thermal insulation wall block

PendingCN108821706AGood heat insulationImprove fire performanceBuilding componentsThermal insulationPolystyrene

A provided expanded vermiculite lightweight thermal insulation wall block includes bed material, medium material, surface material and a grid cloth, the fabric and the bed material are prepared from the following components, by weight: 100 parts of sulphoaluminate cement, 2-8 parts of fly ash, 0.5-3 parts of iron oxide yellow, 0.5-2 parts of silica fume, 2-6 parts of expanded vermiculite, 1-2 parts of mekralon, 0.05-0.1 part of trisodium phosphate, 0.01-0.02 part of organosilicon and 35-50 parts of water; the medium material is prepared from the following components, by weight: 100 parts of the sulphoaluminate cement, 2-8 parts of the fly ash, 0.5-2 parts of the silica fume, 15-25 parts of the expanded vermiculite, 1-5 parts of a polystyrene granule, 0.05-0.1 part of the trisodium phosphate, 0.001-0.01 part of oxalic acid, 0.01-0.02 part of the organosilicon, 0.01-0.015 part of sodium butylnaphthalenesulfonate, and 30-40 parts of the water. The wall block has the advantages of low cost, high strength, long service life, excellent insulation and sound insulation effect, and light weight.

Owner:卓达新材料科技集团潍坊有限公司

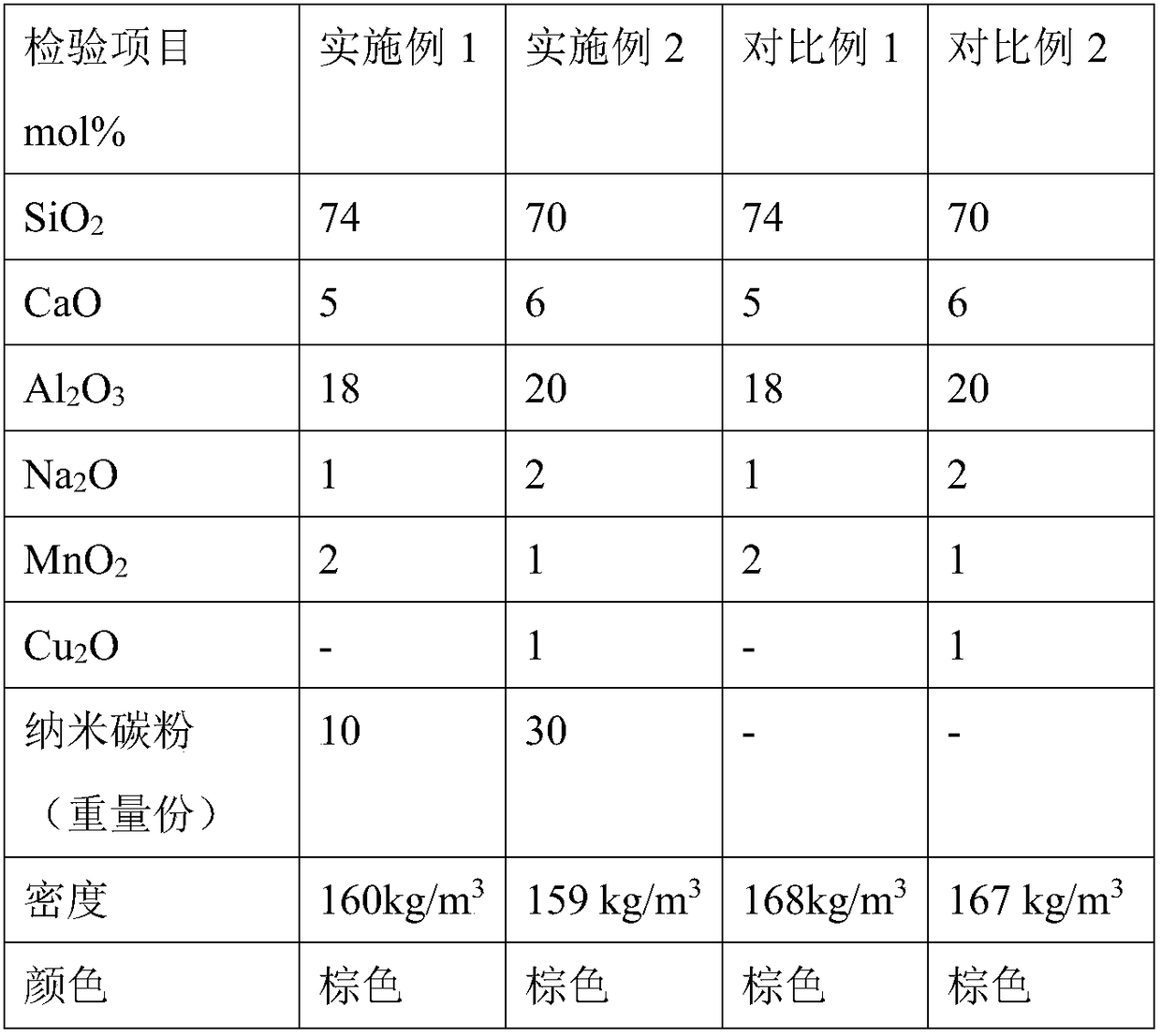

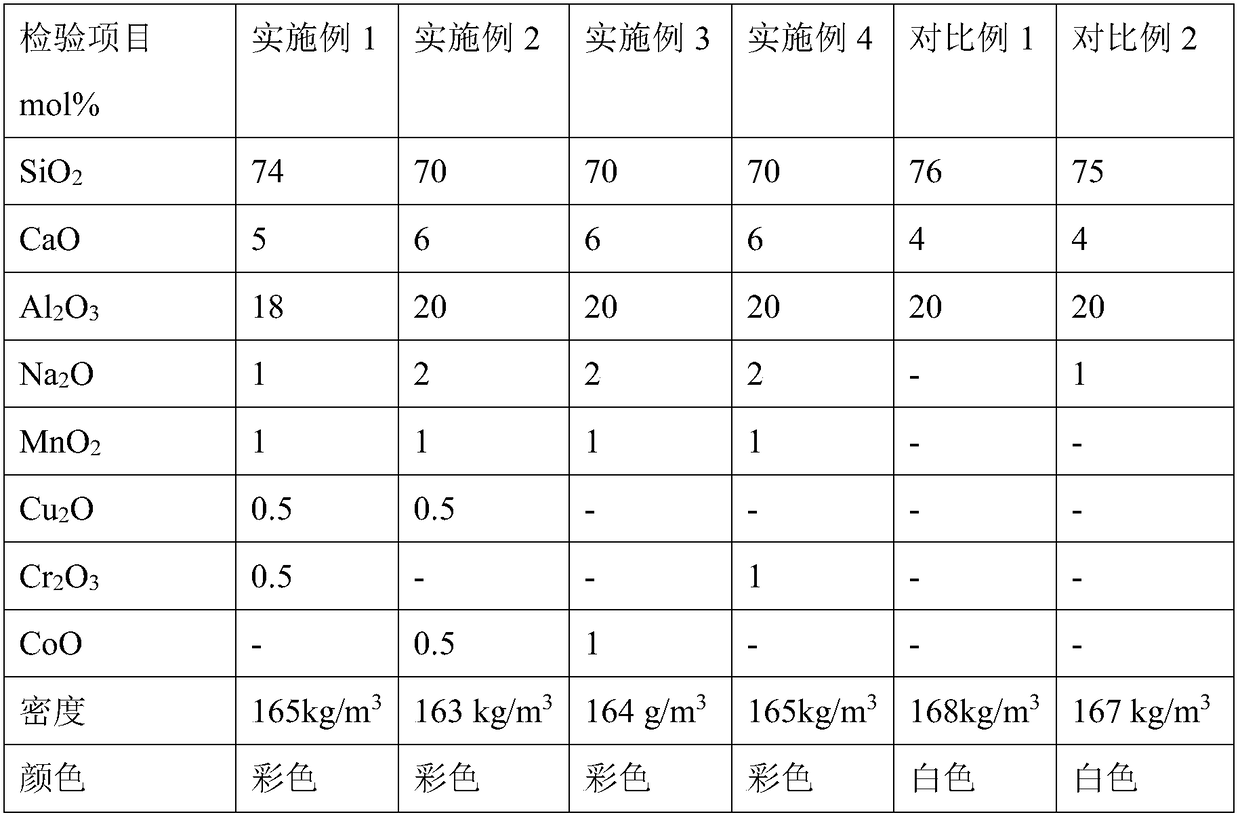

Preparation method of lightweight brown foam glass

PendingCN109020242ALight weight per unit volumeLow sintering temperatureGlass shaping apparatusFoaming agentStress relief

The invention relates to a preparation method of a lightweight brown foam glass, wherein the glass comprises a base component and at least a coloring component, the base component comprises about 70-76 mol% of SiO2, about 5-9 mol% of CaO, 18 mol% to about 22 mol% of Al2O3, and about 1-2 mol% of Na2O, the coloring component comprises: a) more than 0 mol% to about 4 mol% of MnO2, and / or b) more than0 mol% to about 3 mol% of Cu2O, and ball milling mixing, pre-forming, preheating, foaming sintering, cooling and stress relief annealing are performed to obtain the product. According to the presentinvention, the foam glass obtained by adding the additional foaming agent during the pre-forming has characteristics of brown appearance, light weight per unit volume, low sintering temperature and low cost.

Owner:HEBEI ZHUODA BUILDING MATERIALS RES INST CO LTD

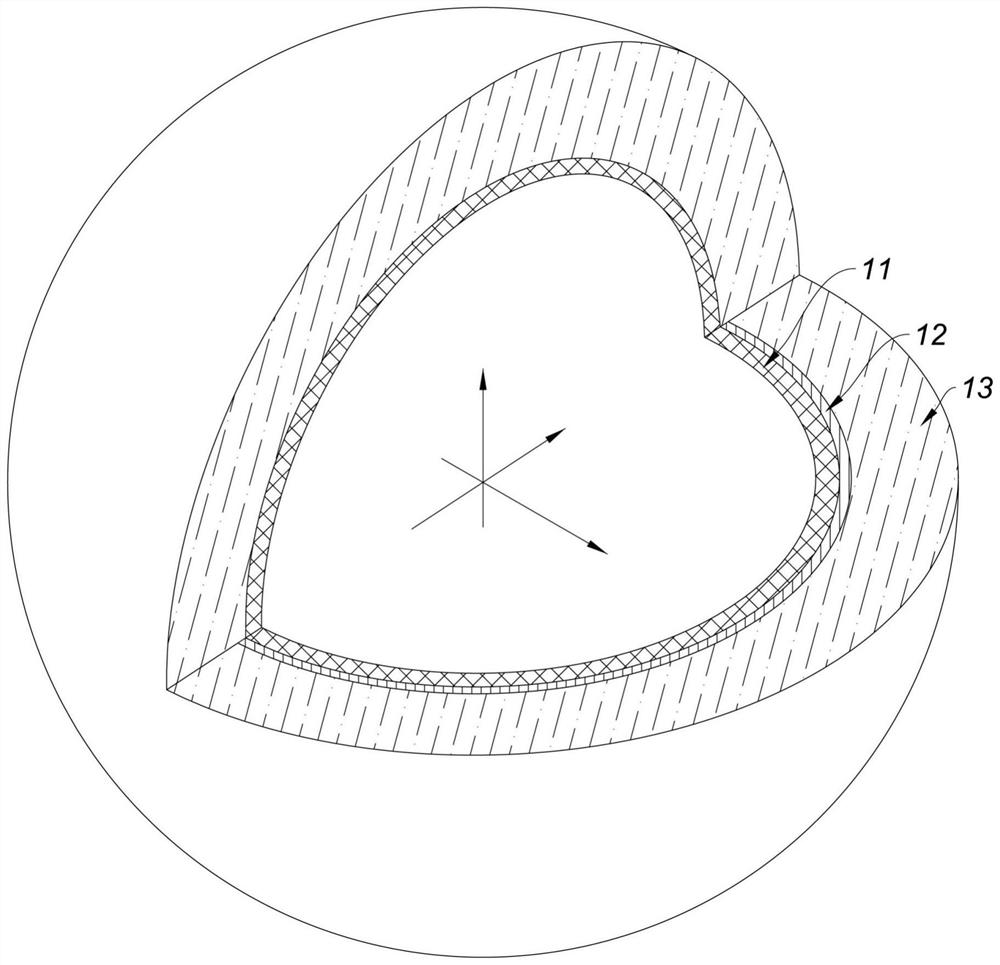

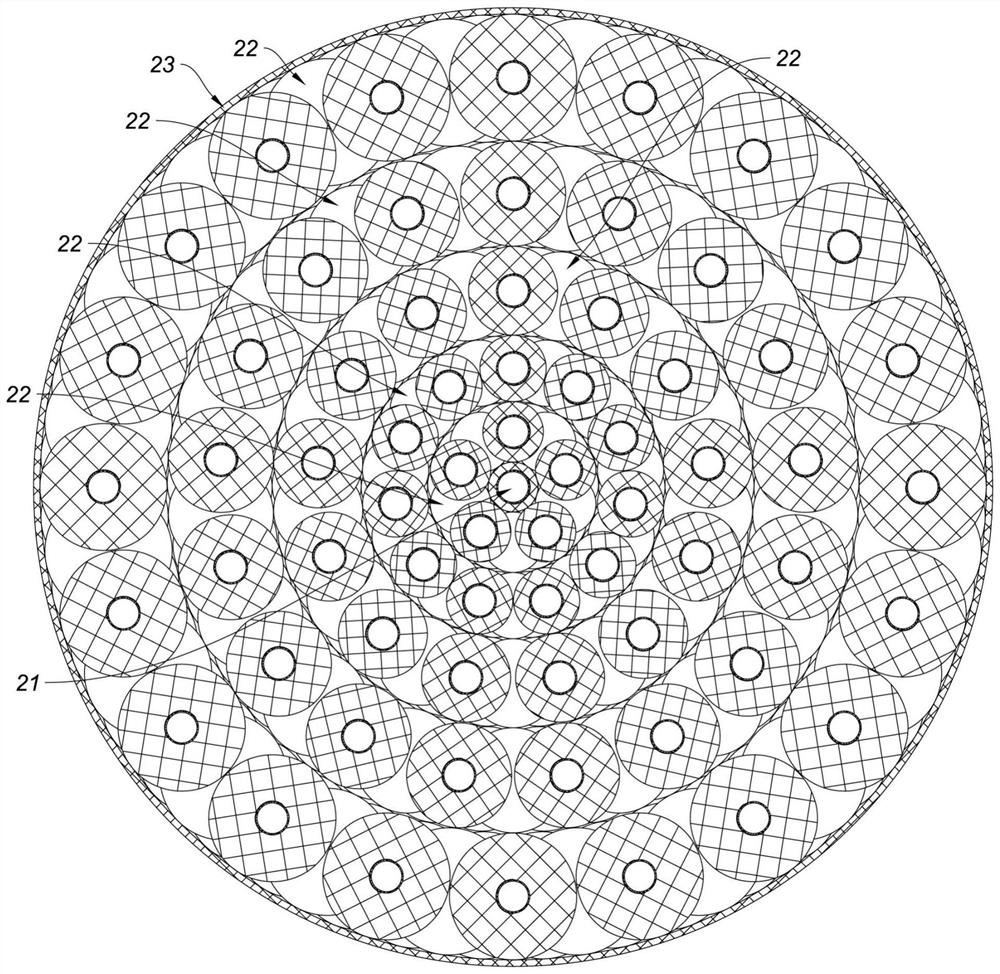

A kind of spherical dielectric material and its production method and Lunberg lens

ActiveCN111463580BSimple structureReasonable designWaveguidesLeaky-waveguide antennasMetallic materialsMaterials science

Owner:CHINA UNITED NETWORK COMM GRP CO LTD +1

Method for reducing density of colored foam glass

PendingCN109020233AOptimize the amount of additionOptimizing the amount of addition can achieve low costGlass shaping apparatusFoaming agentStress relief

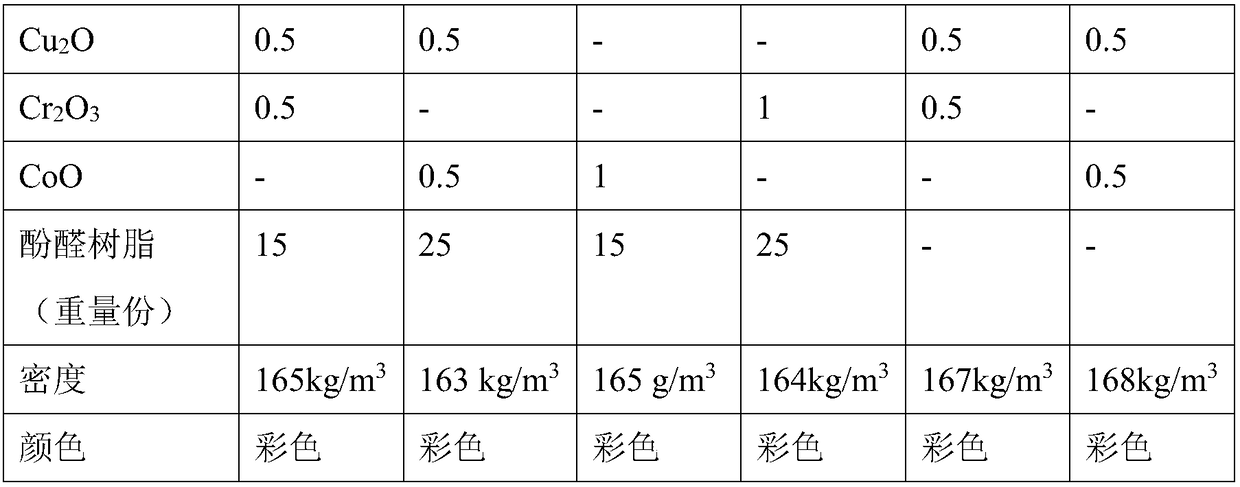

The invention relates to a method for reducing the density of a colored foam glass, wherein the glass comprises a base component and at least a coloring component, the base component comprises about 70-76 mol% of SiO2, about 5-9 mol% of CaO, 18 mol% to about 22 mol% of Al2O3, and about 1-2 mol% of Na2O, the coloring component comprises: a) more than 0 mol% to about 4 mol% of MnO2, and / or b) more than 0 mol% to about 3 mol% of Cu2O, c) more than 0 mol% to about 2 mol% of Cr2O3, and / or d) more than 0 mol% to about 5 mol% of CoO, and ball milling mixing, pre-forming, preheating, foaming sintering, cooling and stress relief annealing are performed to obtain the product. According to the present invention, the foam glass obtained by adding the additional foaming agent during the pre-forming hascharacteristics of low density, color appearance, light weight per unit volume, low sintering temperature and low cost.

Owner:HEBEI ZHUODA BUILDING MATERIALS RES INST CO LTD

Coal cinder sandwich wallboard production method

InactiveCN109333797ALight weight per unit volumeImprove water resistanceCeramic shaping plantsCement mixing apparatusEmulsionSlag

The invention discloses a coal cinder sandwich wallboard production method. The coal cinder sandwich wallboard production method comprises the following materials: coal cinder ash, iron ore slag, powder rock sand, perlite particles and cement form dry mixtures; polystyrene granules, water and multiple additives are added in the dry mixtures; the multiple additives comprise methylcellulose, emulsion powder, early strength agents, water reducing agents and air entraining agents; and a production system comprises a coal cinder ash bucket, an iron furnace slag bucket, a powder rock sand bucket, aperlite particle bucket, a cement bin, a polystyrene granule bin, a raw material bin, a puffing bin, a stirrer, a mold, an expanding unit, a mold car, a belt machine, an electronic scale, a skip, an additive library and a water pump. The coal cinder sandwich wallboard production method is characterized in that the materials in each bucket needed by formulas of 30 boards are unloaded to the belt machined and loaded to the lifting skip to send to the stirrer through control of the electronic scale by a computer; the polystyrene granules are charged in the stirrer; the water and the additives areadded for full stirring; and water mixtures are filled in a prepared combination mold for molding. The coal cinder sandwich wallboard production method can change wastes into valuable things, and canprepare pure natural, green, ecological and environment-friendly wall materials.

Owner:LIXIAN JINHUI GYPSUM PROD +1

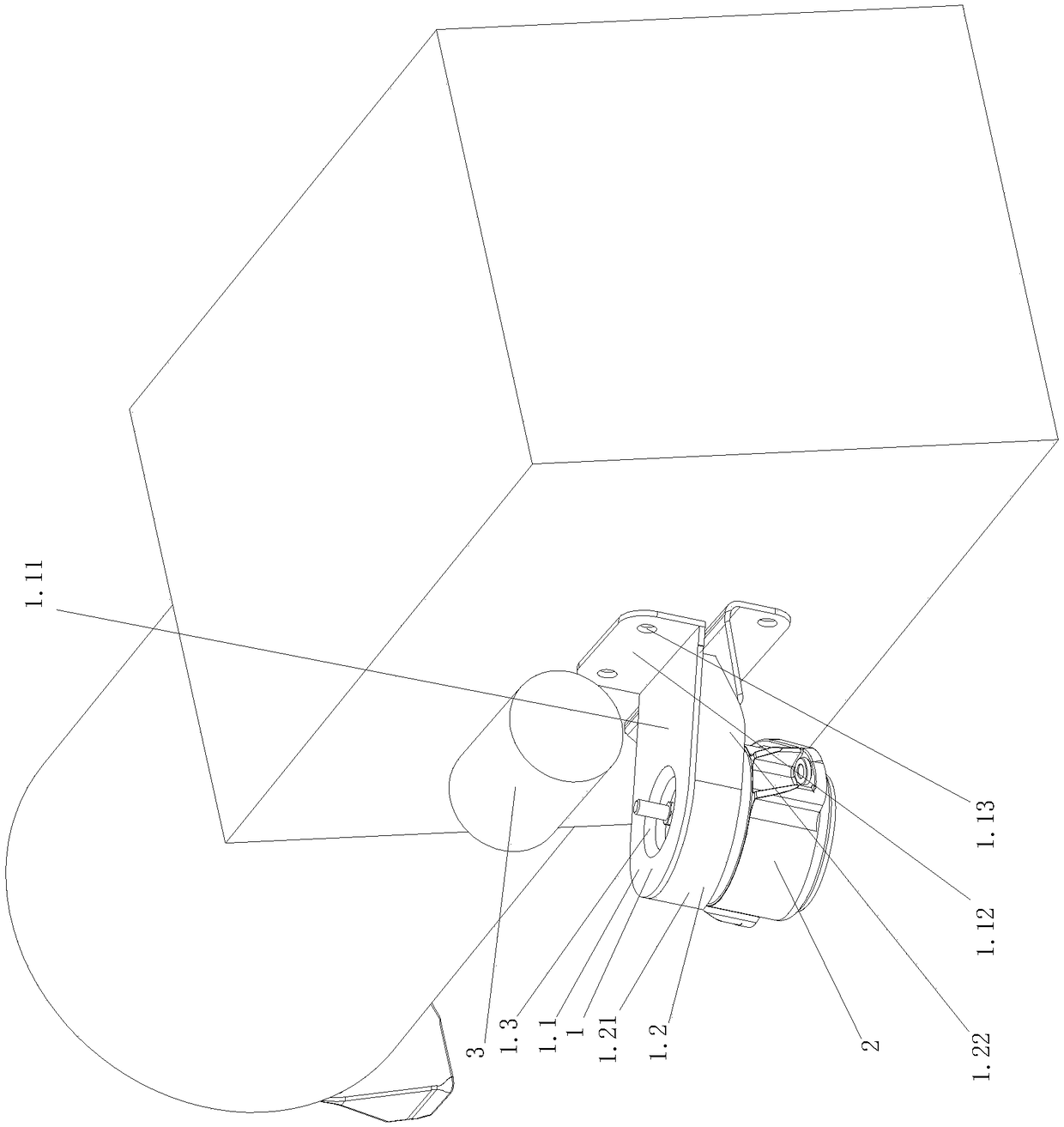

Insulating cover

PendingCN108868992AExtended service lifeEasily damagedExhaust apparatusSilencing apparatusArchitectural engineeringWelding

The utility model relates to an aluminum plate insulating cover, which comprises a main body, an outer cover and an inner cover. The main body of the insulating cover consists of an outer inner coverconnecting part and an insulating cover fixed part connected by vertical lap welding. The outer inner cover connecting part is half round at one end and is provided with a round hole matched with theinner cover in the middle. The outer cover of the insulating cover includes an outer cover semicircular cylinder and two parallel outer cover side walls. The outer cover semicircular cylinder is vertically lap welded with a semicircular of the outer inner cover connecting part. The outer cover side wall is vertically lap welded with the two sides of the outer inner cover connecting part. The innercover of the insulating cover is vertically lap welded with the round hole matched with the inner cover in the middle of the outer cover. The free end of the inner cover and the free end of the outercover are on the same side. The free end of the inner cover and the free end of the outer cover are positioned on one side of the main body of the longitudinal power assembly, and an output shaft ofthe longitudinal power assembly passes through the insulating inner cover.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

Novel light partition board

PendingCN107762062ALight weight per unit volumeLow costConstruction materialRebarMechanical engineering

The invention discloses a novel light partition board. The light partition board comprises a bamboo keel, and connecting holes are reserved in the bamboo keel, connected through pins and fixed throughanti-skid buckles; the two sides of the bamboo keel are connected with gypsum boards through nails. The light partition board has the advantages that the partition board is environmentally friendly,the house space is enlarged, the integrity is good, construction is easy and efficient, materials are convenient to obtain, and the partition board is light and economical. Compared with traditional steel reinforcement framework partitions, plate partition, glass partitions and light building block partitions, the novel light partition board has the advantages of being low in manufacturing cost, long in service life, high in strength, low in weight per unit volume and the like.

Owner:朱兆健 +1

Plant polysaccharide sponge body and its preparation method

The invention discloses a plant polysaccharide sponge and a preparation method thereof. Using plant polysaccharides as raw materials, adding fillers, plasticizers, softeners, foaming agents, waterproofing agents and preservatives, after being melted and plasticized by the extruder at high temperature, the honeycomb sponge structure is obtained, and sent to the shaping mechanism for stable shaping , Extrude the sponge product through the mold. The products can be widely used in sanitary materials, medical dressings, agriculture, forestry and gardening, daily chemicals, construction, sofas and car cushions.

Owner:姜发堂

Ceramic discs for food grinding

ActiveCN105536929BSolve the strength problemSolve wear resistanceCocoaGrain treatmentsUltimate tensile strengthMaterials science

A ceramic grinding disc for food grinding processing solves the problems that for an existing grinding disc, foodstuff distribution is nonuniform, the diversion speed is low, discharging is difficult, feeding blocking is prone to be caused, and the grinding efficiency is low. The ceramic grinding disc is characterized in that the internally-concave conical surface of a fixed grinding disc body is provided with symmetrical step-shaped oblique teeth, and the internally-concave plane of a movable grinding disc body is provided with material guide grooves and trapezoid teeth; according to the movable grinding disc body, multiple trapezoid teeth which are independent and are mutually staggered form a grinding tooth array, and according to the fixed grinding disc body, multiple independent symmetrical step-shaped oblique teeth form the internally-concave conical grinding surface. The ceramic grinding disc for food grinding processing has the advantages that foodstuffs conduct dynamic collision with the movable grinding disc body and the fixed grinding disc body in an internally-concave conical grinding cavity between the movable grinding disc body and the fixed grinding disc body, the flowing velocity of the foodstuffs is increased under the synergistic action of extruding, breaking, shearing and grinding, secondary grinding is conducted through the two peripheral grinding surfaces of the movable grinding disc body and the fixed grinding disc body, the ground foodstuffs are filtered and flow out of grinding and screening gaps, the grinding efficiency and the grinding effect are improved, and the grinding disc is high in strength, good in wear-resisting property, long in service life and suitable for industrialized continuous production.

Owner:LIAONING YINGGUAN HIGH TECH CERAMIC CO LTD

Preparation method of colored foam glass

The invention relates to a preparation method of a colored foam glass, wherein the glass comprises a base component and at least a coloring component, the base component comprises about 70-76 mol% ofSiO2, about 5-9 mol% of CaO, 18 mol% to about 22 mol% of Al2O3, and about 1-2 mol% of Na2O, the coloring component comprises: a) more than 0 mol% to about 4 mol% of MnO2, and / or b) more than 0 mol% toabout 3 mol% of Cu2O, c) more than 0 mol% to about 2 mol% of Cr2O3, and / or d) more than 0 mol% to about 5 mol% of CoO, and ball milling mixing, pre-forming, preheating, foaming sintering, cooling andstress relief annealing are performed to obtain the product. According to the present invention, the foam glass obtained by using the method has characteristics of color appearance, light weight perunit volume, low sintering temperature and low cost.

Owner:HEBEI ZHUODA BUILDING MATERIALS RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com