Non-woven fibric containing filament batt, manufacturing method and used as cleaning cloth

A technology for non-woven fabrics and wool layers, which can be used in non-woven fabrics, fabrics, cleaning machinery, etc., and can solve problems such as low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

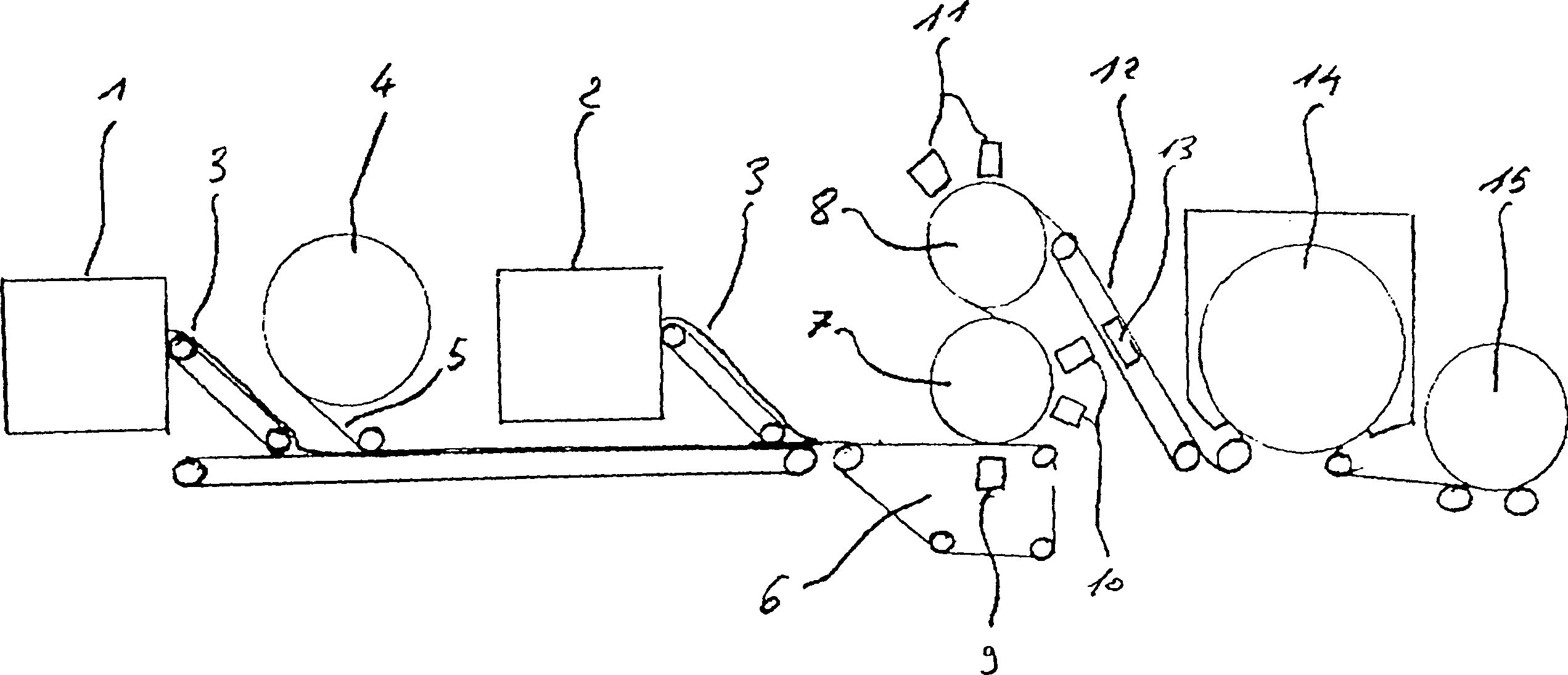

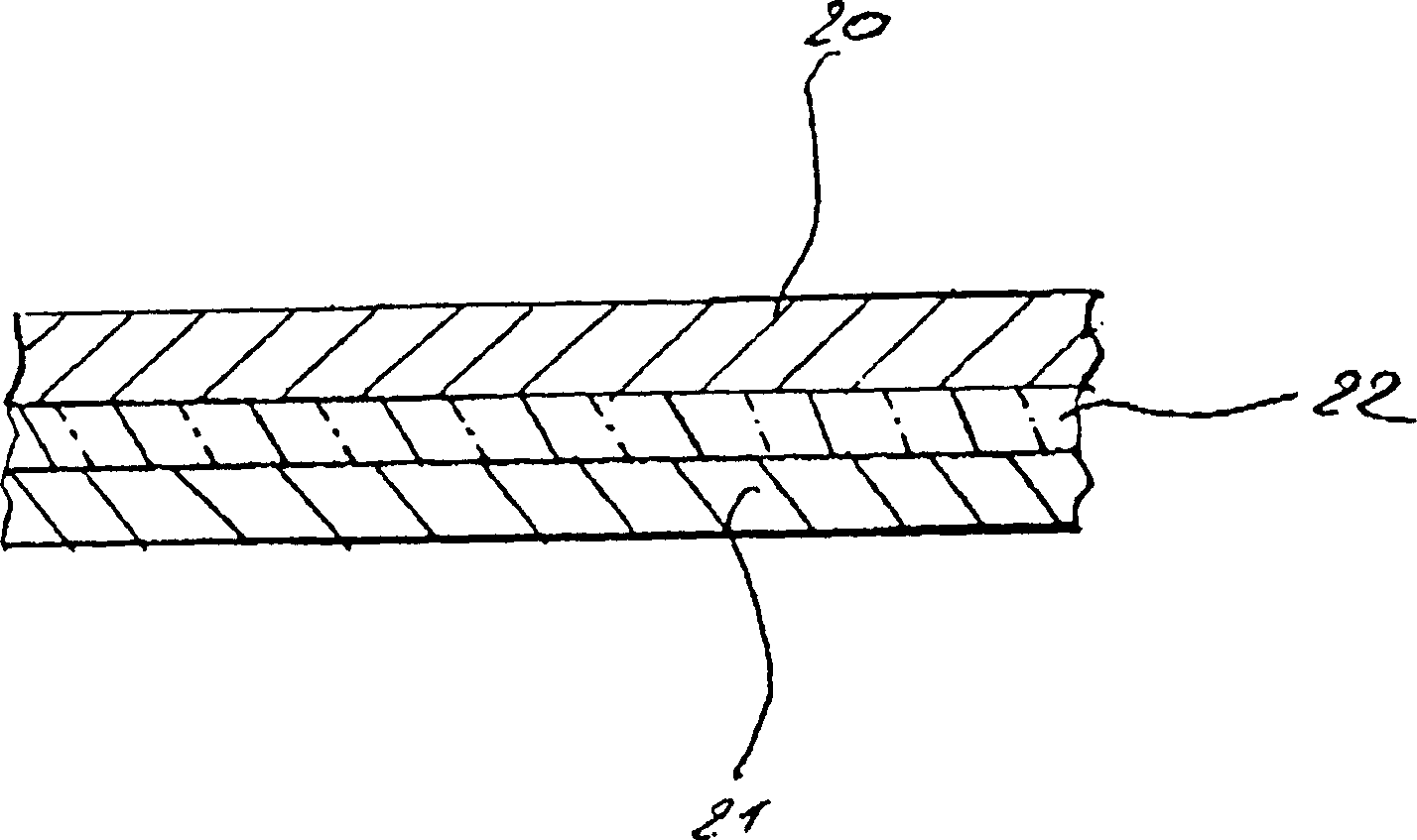

[0105] A lightly rolled spunbond polypropylene filament batt (20 g / m 2 ) placed in two 20g / m 2 Comb between polyester webs. The polyester fiber has a linear density of 1.7dtex and a length of 38mm. Such an assembly of three laminated layers is used in e.g. figure 1 The equipment shown is subjected to the action of water spray, and the consolidation energy is 0.12kwh / kg. Then, the nonwoven fabric thus obtained was dried in a ventilated oven at a temperature of 120°C at a rate of 20 m / min. The obtained weight per unit area is 60g / m 2 1. A nonwoven fabric having a ratio R of longitudinal tensile breaking strength to transverse direction of less than 2.

Embodiment 2

[0107] Repeat Example 1, with 2 20g / m 2 The polypropylene mesh replaces the two polyester meshes. The polypropylene fiber had a linear density of 1.7 dtex and a length of 40 mm. Such an assembly of three laminated layers is used in e.g. figure 1 The equipment shown is subjected to the action of water spray, and the consolidation energy is 0.12kwh / kg. Then, the nonwoven fabric thus obtained was dried in a ventilated oven at a temperature of 120°C at a speed of 20 m / min. The obtained weight per unit area is 60g / m 2 , R less than 2 non-woven fabrics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com