Composite packaging material prepared by utilizing municipal sludge and preparation method thereof

A composite packaging material and municipal sludge technology, applied in the field of sludge environmental protection treatment, can solve the problems of limited urban sludge resource utilization, unfavorable urban sludge promotion and utilization, health hazards, etc., to achieve good foaming effect, The effect of simple preparation process and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

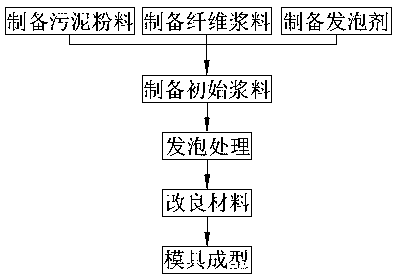

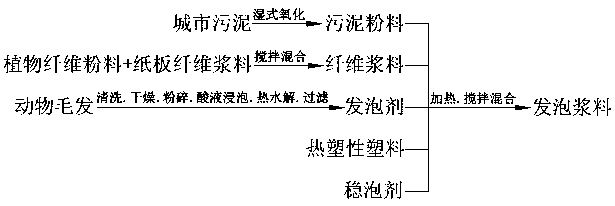

[0035] Such as Figure 1-3 As shown, a composite packaging material prepared from municipal sludge includes foaming slurry prepared by mixing and stirring sludge powder, fiber slurry and foaming agent, and the sludge powder is passed through municipal sludge It is produced through physical and chemical treatment for decomposing organic matter, and the content of organic matter in the sludge powder is less than 10%.

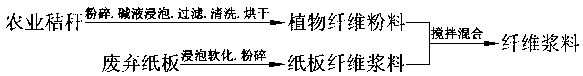

[0036] In the composite packaging material prepared by using municipal sludge in this embodiment, the physical and chemical treatment for decomposing organic matter is preferably wet oxidation treatment, and the fiber slurry includes plant fibers made from agricultural straw, so that at the same time it is Municipal sludge and agricultural straw provide an economical and environmentally friendly way of resource utilization, making full use of cellulose, silicon oxide and various metal oxides in municipal sludge, combined with cellulose in plant fibers and protein ...

Embodiment 2

[0040] Such as Figure 1-3 As shown, a composite packaging material prepared from municipal sludge in this embodiment has the same raw material composition as that in Embodiment 1, except that the foaming agent includes protein liquid obtained from animal hair through protein extraction.

[0041] A composite packaging material prepared from urban sludge in this embodiment uses animal hair as a raw material for preparing a foaming agent, and uses animal hair to prepare protein liquid as a foaming agent, which not only has a good foaming effect, but also has a good The foam stabilizing effect further makes the raw materials environmentally friendly, has a wide range of sources, and is low in cost. The composite packaging material produced is light in material, has good thermal insulation effect, and provides a better resource utilization method for animal hair. This implementation For example, the animal hair is preferably poultry feathers, forming an environmentally friendly co...

Embodiment 3

[0043] Such as Figure 1-3 As shown, a composite packaging material prepared from municipal sludge in this embodiment has the same raw material composition as in Example 1, the difference is that it also includes a material modifier. In this embodiment, it is preferred that the material modifier includes thermoplastics and stabilizers. foaming agent.

[0044] In this embodiment, a composite packaging material prepared from municipal sludge, by adding thermoplastics to the foamed slurry, the composite packaging material can not only achieve the packaging effect of ordinary cardboard packaging materials, but also have the characteristics of plastic boards. characteristics, so that the prepared composite packaging material has excellent performances of waterproof, moisture resistance, insect resistance, and antibacterial, and the surface roughness is smaller. At the same time, adding a foam stabilizer to the foaming slurry is beneficial to make the foaming slurry The number of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com