Grouting bag and application method

A grouting bag and grouting technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of vertical steel shear keys that cannot be effectively cushioned, uneven settlement of pipe joints, and failure of shear structures and other problems, to avoid local stress concentration problems, occupy a small space, and achieve the effect of safe and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The invention provides a grouting bag;

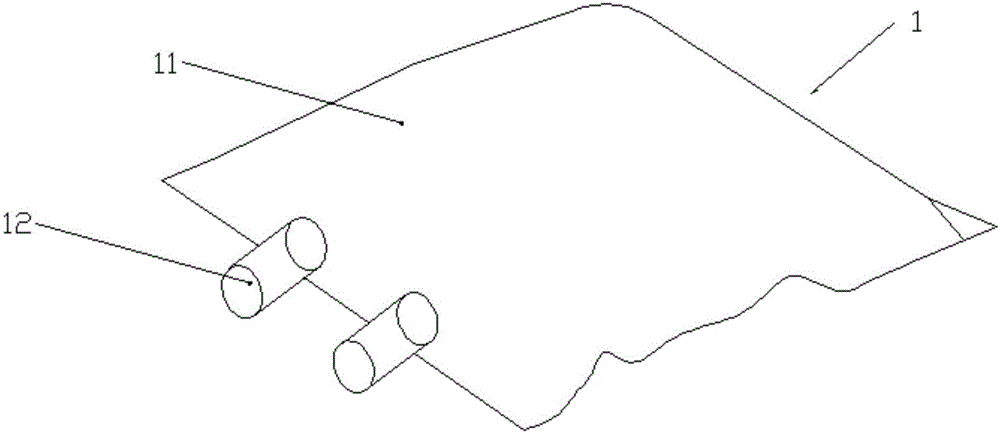

[0035] Such as figure 1 As shown, the grouting bag 1 in this embodiment includes an integrally sealed bag body 11 whose shape and size can be customized according to the needs of use. The bag body 11 is provided with two grouting ports 12 for use During grouting or degassing in the process, the bag body is made of elastic material, and when curable grout is injected into the bag body 11, the bag body can expand automatically with the grout entering.

[0036]The grouting bag in the present invention is integrally sealed and made of elastic material, and has certain plasticity and ductility. When grouting into the bag, the volume can expand and fill the space where it is located. In the irregular shear support system formed by uneven settlement, the grouting bladder can fully fill the space around its location, and through its own deformation, it can cling to the plane of the irregular steel shear key members on both sides , afte...

Embodiment 2

[0040] The present invention also provides a method for using the grouting pouch, comprising the following steps:

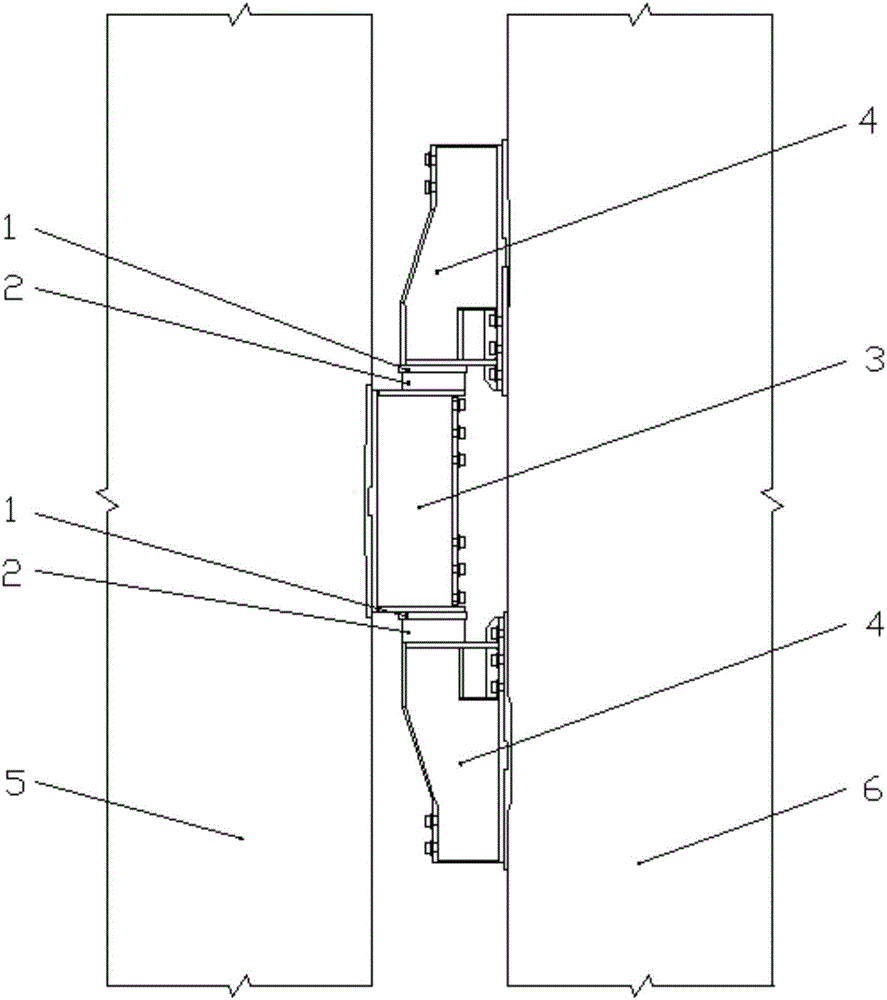

[0041] a. If figure 2 As shown, after the vertical steel shear key 3 and steel shear key 2 4 are respectively connected with the embedded parts of the first end 5 of the immersed tube and the second end 6 of the immersed tube through high-strength bolts, the steel shear key Put the steel backing plate 2 between the shear force key 1 3 and the steel shear force key 2 4;

[0042] b. Place the grouting bag 1 flat on the center of the steel backing plate 2, make the grouting port 12 on the grouting bag 1 face outward and connect the grouting pipe;

[0043] c. Inject curable grout into the grouting bladder 1, stop grouting when the grouting pressure reaches the requirement and maintain the pressure for a period of time.

[0044] The method of using the grouting bladder is to reduce the component spacing by placing steel backing plates between the steel shear keys, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com