A vitreous microbead lightweight thermal insulation wall block

A vitrified microbead and thermal insulation technology, applied in building components, buildings, building structures, etc., can solve the problems of heavy cement board weight, reduced production efficiency, and inability to move at will, achieving light weight per unit volume and long service life. , the effect of low price of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

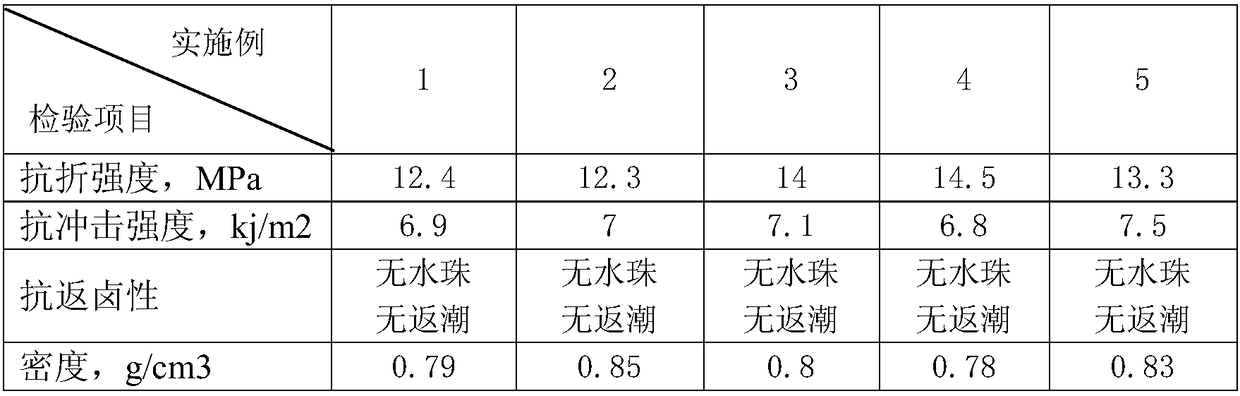

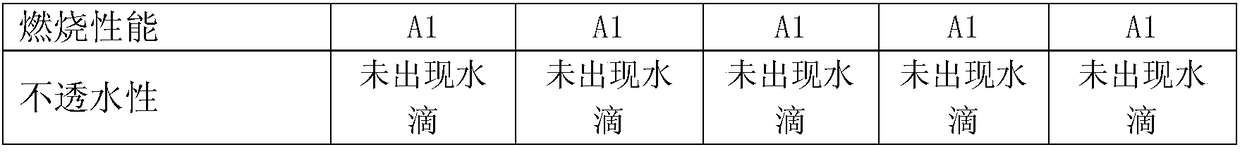

Examples

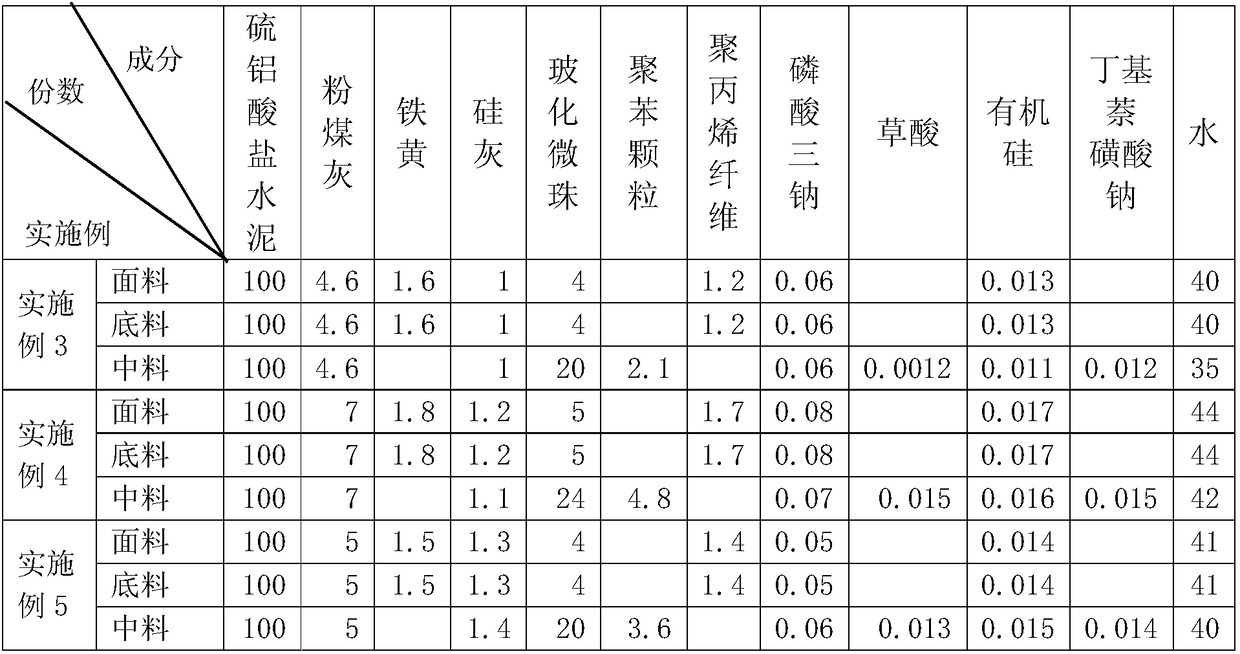

Embodiment 1

[0023] A vitrified microbead lightweight thermal insulation wall block, the lightweight thermal insulation wall block includes a base material, a middle material, a fabric, and a grid cloth, wherein:

[0024] Both the fabric and the base material are composed of the following components in parts by weight: 100 parts of sulphoaluminate cement, 4 parts of fly ash, 1.6 parts of iron yellow, 1.2 parts of silica fume, 3.8 parts of vitrified microbeads and 1.3 parts of polypropylene fiber 0.07 parts of trisodium phosphate, 0.014 parts of organic silicon, 41 parts of water;

[0025] The middle material is composed of the following components by weight: 100 parts of sulfoaluminate cement, 3.2 parts of fly ash, 0.6 part of silica fume, 19 parts of vitrified microbeads, 2.7 parts of polyphenylene particles, and 0.07 parts of trisodium phosphate , 0.003 parts of oxalic acid, 0.015 parts of silicone, 0.013 parts of sodium butyl naphthalene sulfonate, and 33 parts of water.

[0026] In an...

Embodiment 2

[0028] A vitrified microbead lightweight thermal insulation wall block, the lightweight thermal insulation wall block includes a base material, a middle material, a fabric, and a grid cloth, wherein:

[0029] Both the fabric and the bottom material are composed of the following components by weight: 100 parts of sulphoaluminate cement, 5 parts of fly ash, 0.6 parts of iron yellow, 1.5 parts of silica fume, 4.5 parts of vitrified microbeads, polypropylene fiber 1.3 parts, 0.07 parts of trisodium phosphate, 0.016 parts of organic silicon, 40 parts of water;

[0030] The middle material is composed of the following components by weight: 100 parts of sulfoaluminate cement, 3 parts of fly ash, 0.7 part of silica fume, 21 parts of vitrified microspheres, 4 parts of polyphenylene particles, and 0.08 part of trisodium phosphate , 0.006 parts of oxalic acid, 0.018 parts of silicone, 0.013 parts of sodium butyl naphthalene sulfonate, and 35 parts of water.

[0031] In an environment wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com