Preparation method of colored foam glass

A foam glass and glass technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of unsightly cost and other problems, and achieve the effect of low raw material price, low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

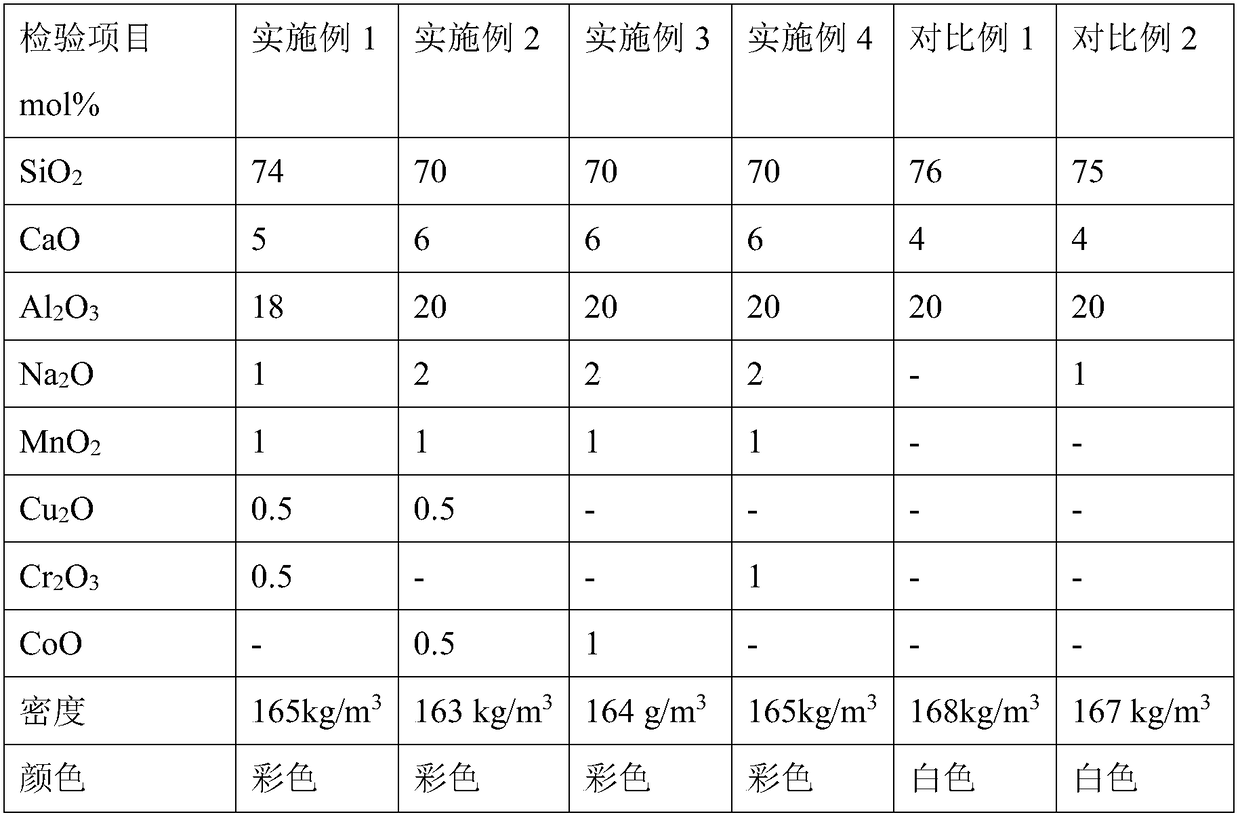

Embodiment 1

[0019] A colored foam glass comprising an essential component and at least one colored component: the essential component comprising: 74 mol % SiO 2 ; 5 mol% CaO; 18 mol% Al 2 o 3 ; 1 mol% Na 2 O; the at least one coloring component comprises: 1 mol % of MnO 2 , 0.5 mol% Cu 2 O, 0.5 mol% Cr 2 o 3 .

[0020] Described colored cellular glass obtains as follows:

[0021] 1) Preparation of premix: 100 parts of aluminosilicate glass powder with a particle size of 500 mesh or more, 10 parts of calcium carbonate, alkali metal oxide Na 2 O 2 parts, colorant (MnO 2 , Cu 2 O and Cr 2 o 3 ) 2 parts were mixed, an appropriate amount of water was added, the ball-to-material ratio was 50:1, the rotating speed was 100-300rpm, and the ball milled for 30min, the said parts were parts by weight;

[0022] 2) Put the mixture into a foaming furnace and sinter according to the following process: from room temperature to 400°C at a heating rate of 10°C / min, keep warm for 60 minutes for p...

Embodiment 2

[0025] A colored foam glass comprising an essential component and at least one colored component: the essential component comprising: 70 mol % SiO 2 ; 6 mol% CaO; 20 mol% Al 2 o 3 ; 2 mol% Na 2 O; the at least one coloring component comprises: 1 mol % of MnO 2 , 0.5 mol% Cu 2 O, 0.5 mol% CoO.

[0026] Described colored cellular glass obtains as follows:

[0027] 1) Preparation of premix: 100 parts of aluminosilicate glass powder with a particle size of 500 mesh or more, 8 parts of calcium carbonate, alkali metal oxide Na 2 O 4 parts, colorant (MnO 2 , Cu 2 O and CoO) are mixed in 2 parts, an appropriate amount of water is added, the ball-to-material ratio is 70:1, the rotation speed is 100-300rpm, and the ball mill is 30min, and the parts are parts by weight;

[0028] 2) Put the mixture into a foaming furnace and sinter according to the following process: from room temperature to 400°C at a heating rate of 15°C / min, keep warm for 60 minutes for preheating, raise to 950...

Embodiment 3

[0031] A colored foam glass comprising an essential component and at least one colored component: the essential component comprising: 70 mol % SiO 2 ; 6 mol% CaO; 20 mol% Al 2 o 3 ; 2 mol% Na 2 O; the at least one coloring component comprises: 1 mol % of MnO2 , 1 mol% CoO.

[0032] Described colored cellular glass obtains as follows:

[0033] 1) Preparation of premix: 100 parts of aluminosilicate glass powder with a particle size of 500 mesh or more, 8 parts of calcium carbonate, alkali metal oxide Na 2 O4 parts, colorant (MnO 2 Mix with 2 parts of CoO), add an appropriate amount of water, the ball-to-material ratio is 70:1, the rotation speed is 100-300rpm, and the ball mill is 30min, and the parts are parts by weight;

[0034] 2) Put the mixture into a foaming furnace and sinter according to the following process: from room temperature to 400°C at a heating rate of 15°C / min, keep warm for 60 minutes for preheating, raise to 950°C at 20°C / min, and hold for 30 minutes Mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com