Preparation method of lightweight brown foam glass

A foam glass and brown technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problem of unsightly cost and achieve the effect of low raw material price, low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

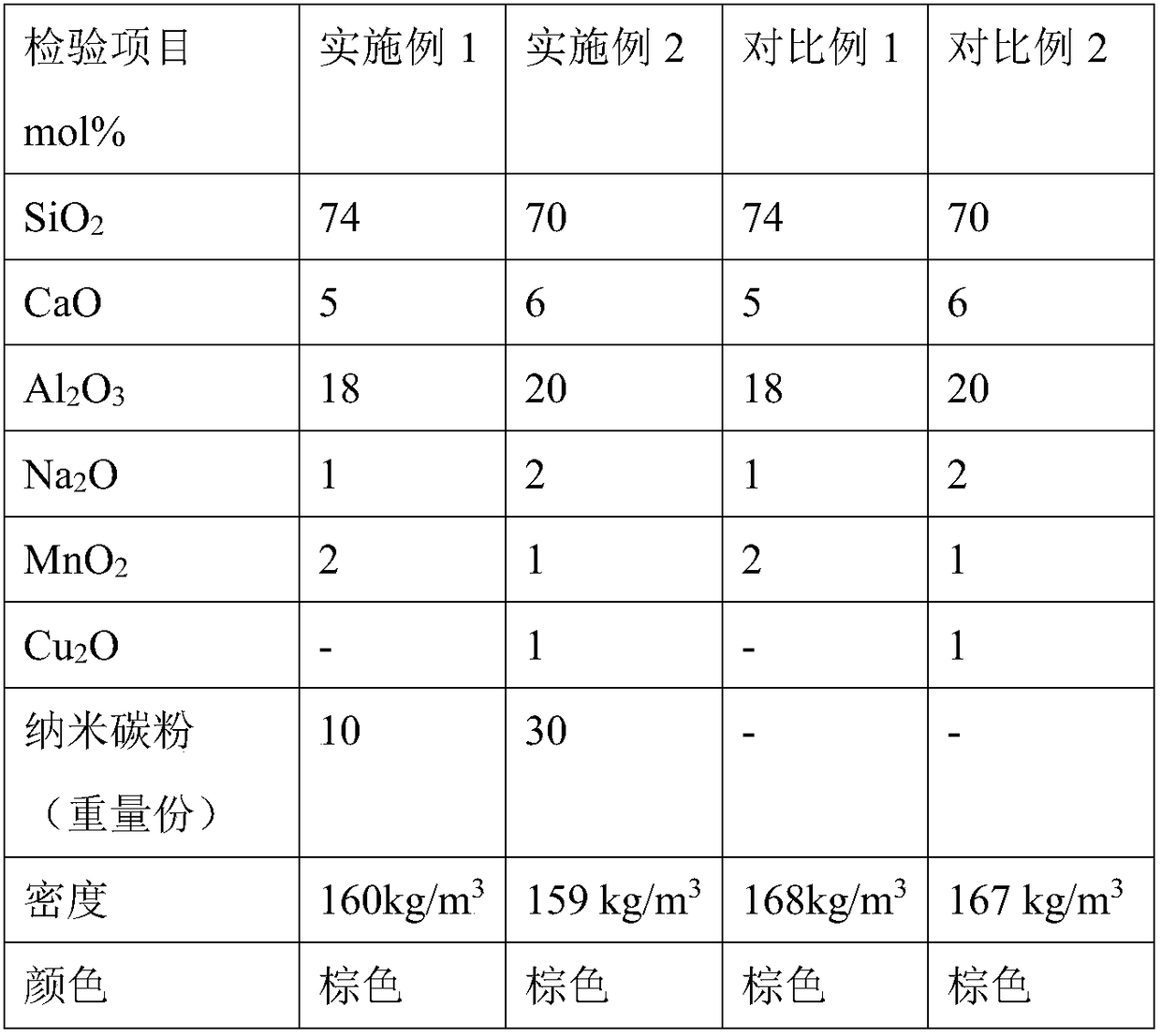

Embodiment 1

[0020] A lightweight brown foam glass comprising an essential component and at least one coloring component: the essential component comprising: 74 mol % SiO 2 ; 5 mol% CaO; 18 mol% Al 2 o 3 ; 1 mol% Na 2 O; the at least one coloring component comprises: 2 mol % of MnO 2 .

[0021] Described lightweight brown cellular glass is obtained as follows:

[0022] 1) Preparation of premix: 100 parts of aluminosilicate glass powder with a particle size of 500 mesh or more, 10 parts of calcium carbonate, alkali metal oxide Na 2 O2 parts, coloring agent MnO 2 2 parts are mixed, add an appropriate amount of water, the ball-to-material ratio is 50:1, the rotation speed is 100-300rpm, and the ball mill is 30min, and the stated parts are parts by weight;

[0023] 2) Based on the calculation of 100 parts of the prepared premix, add 10 parts of nano-carbon powder and mix evenly, place it in the mold and pre-pressurize it to form a preform, and the pressure is 1 MPa;

[0024] 3) Put the ...

Embodiment 2

[0027] A lightweight brown foam glass comprising an essential component and at least one coloring component: the essential component comprising: 70 mol % SiO 2 ; 6 mol% CaO; 20 mol% Al 2 o 3 ; 2 mol% Na 2 O; the at least one coloring component comprises: 1 mol % of MnO 2 , 1 mol% Cu 2 O.

[0028] Described lightweight brown cellular glass is obtained as follows:

[0029] 1) Preparation of premix: 100 parts of aluminosilicate glass powder with a particle size of 500 mesh or more, 8 parts of calcium carbonate, alkali metal oxide Na 2 O4 parts, colorant (MnO 2 and Cu 2 O) 2 parts are mixed, add an appropriate amount of water, the ball-to-material ratio is 70:1, the rotating speed is 100-300rpm, and the ball mill is 30min, and the parts are parts by weight;

[0030] 2) Calculated on the basis of 100 parts of the prepared premix, add 30 parts of nano-carbon powder and mix evenly, place it in the mold and pre-pressurize to form a preform, and the pressurization pressure is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com