Production method of cinder sandwich type wall panel

A production method and wallboard technology, which are applied in chemical instruments and methods, cement mixing devices, supply devices, etc., can solve the problems of high force cost in building mechanics, heavy unit volume of masonry, and large amount of steel, and can achieve land occupation. The effect of small area, low production cost and high reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0040] The raw material formula includes: cinder ash 10%, iron slag 20%, powder rock sand 5%, perlite particles 20%, and cement 45% to form a dry mix.

[0041] Add 2.3m polystyrene particles per ton of dry mix 3 .

[0042] Add 230kg of water per ton of dry mix.

[0043] Add 1.5% of various additives per ton of dry mix.

[0044] 1.5% of various additives include: 1.6kg of hydroxypropyl methylcellulose, 0.5kg of dispersible latex powder, 10.5kg of early strength agent, 500ml of water reducing agent, and 1200ml of air-entraining agent to form a water mixture.

[0045] The iron slag and perlite particles are crushed with a crusher, and the particles are within 20mm, which are used as aggregates.

[0046] The water mixture is poured into the prepared combination mold for molding.

specific Embodiment 2

[0048] The raw material formula includes: 5% cinder ash, 25% iron slag, 10% powder rock sand, 10% perlite particles, and 50% cement to form a dry mix.

[0049] 2.4m of polystyrene particles per ton of dry mix 3 .

[0050] Add 250kg of water per ton of dry mix.

[0051] Add 1.8% of various additives per ton of dry mix.

[0052] 1.8% of various additives include: 2.0kg of hydroxypropyl methylcellulose, 0.7kg of dispersible latex powder, 12kg of early strength agent, 700ml of water reducing agent, and 1400ml of air-entraining agent to form a water mixture.

[0053] The iron slag and perlite are crushed with a crusher, and the particles are within 20mm, which are used as aggregates.

[0054] The water mixture is poured into the prepared combination mold for molding.

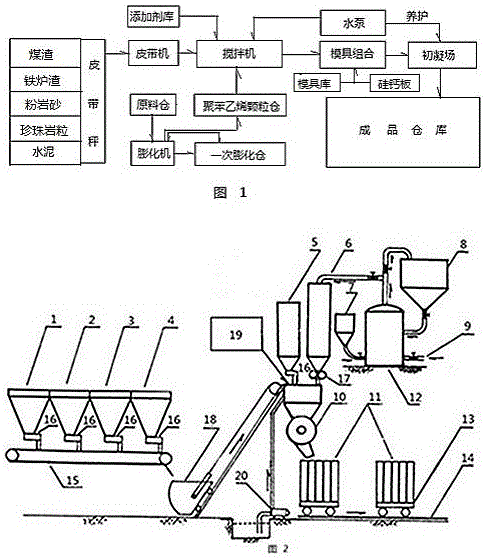

[0055] See attached figure 2 : A cinder sandwich wallboard production system, comprising: cinder ash hopper 1, iron slag hopper 2, powder rock sand hopper 3, perlite granule hopper 4, and cement silo 5. 16 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com