Modularized wallboard structure

A modular and wall panel technology, which is applied to building components, building structures, buildings, etc., can solve problems such as unsatisfactory load-bearing capacity and structural stability, unsatisfactory sound insulation and thermal insulation effects, and insufficient structural strength of wall panels, etc., to achieve Good thermal insulation and sound insulation effects, light weight, and the effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

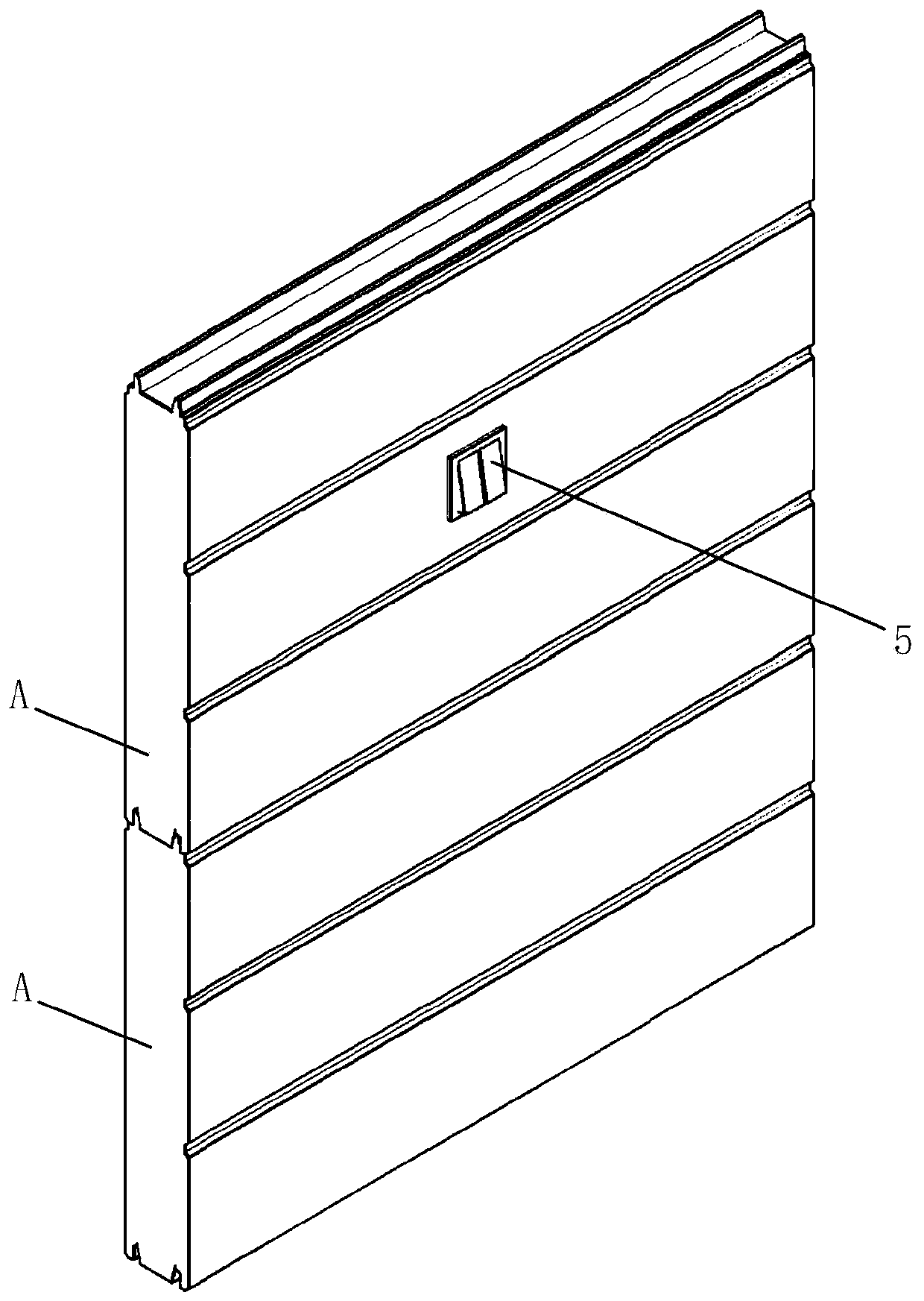

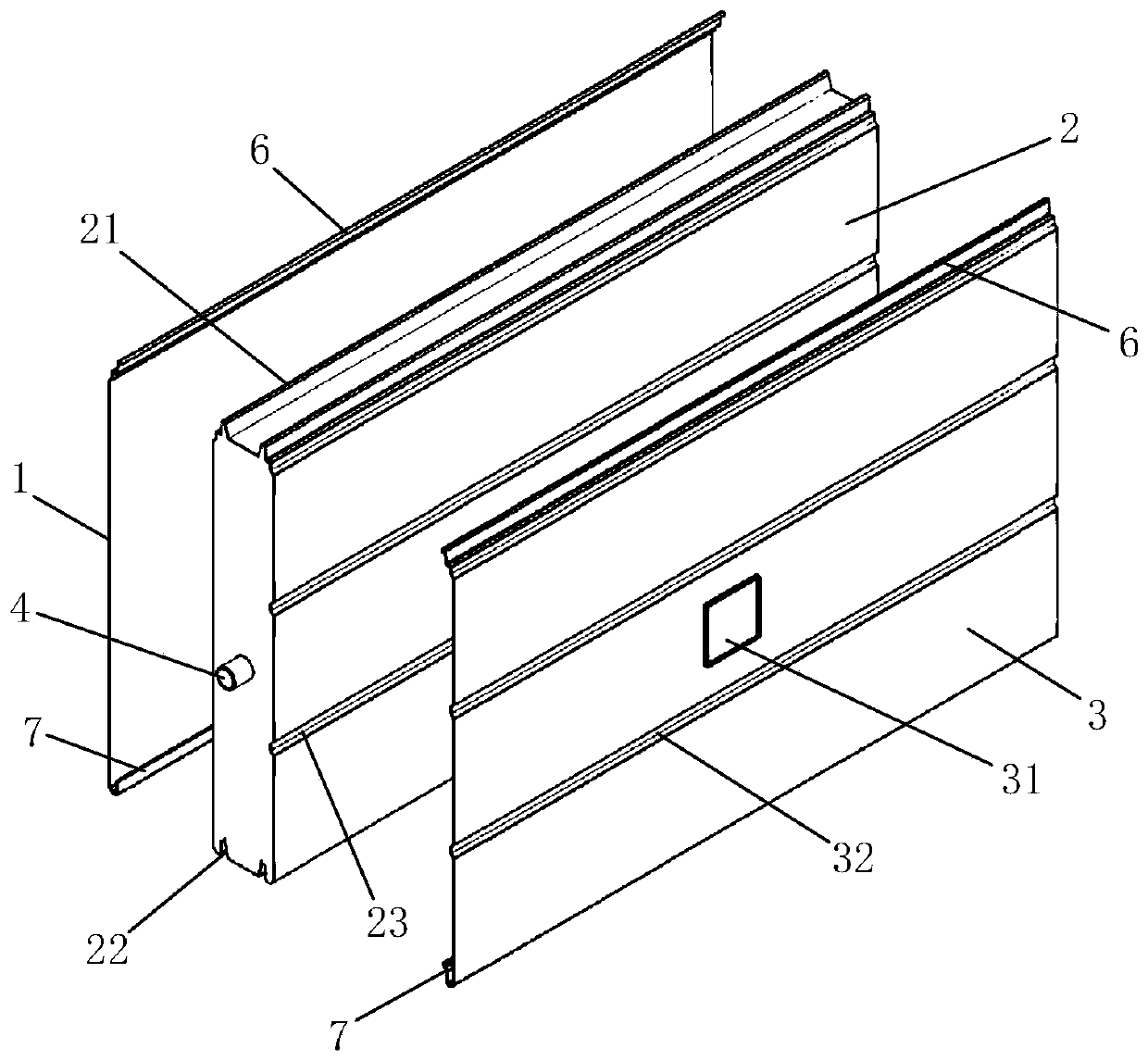

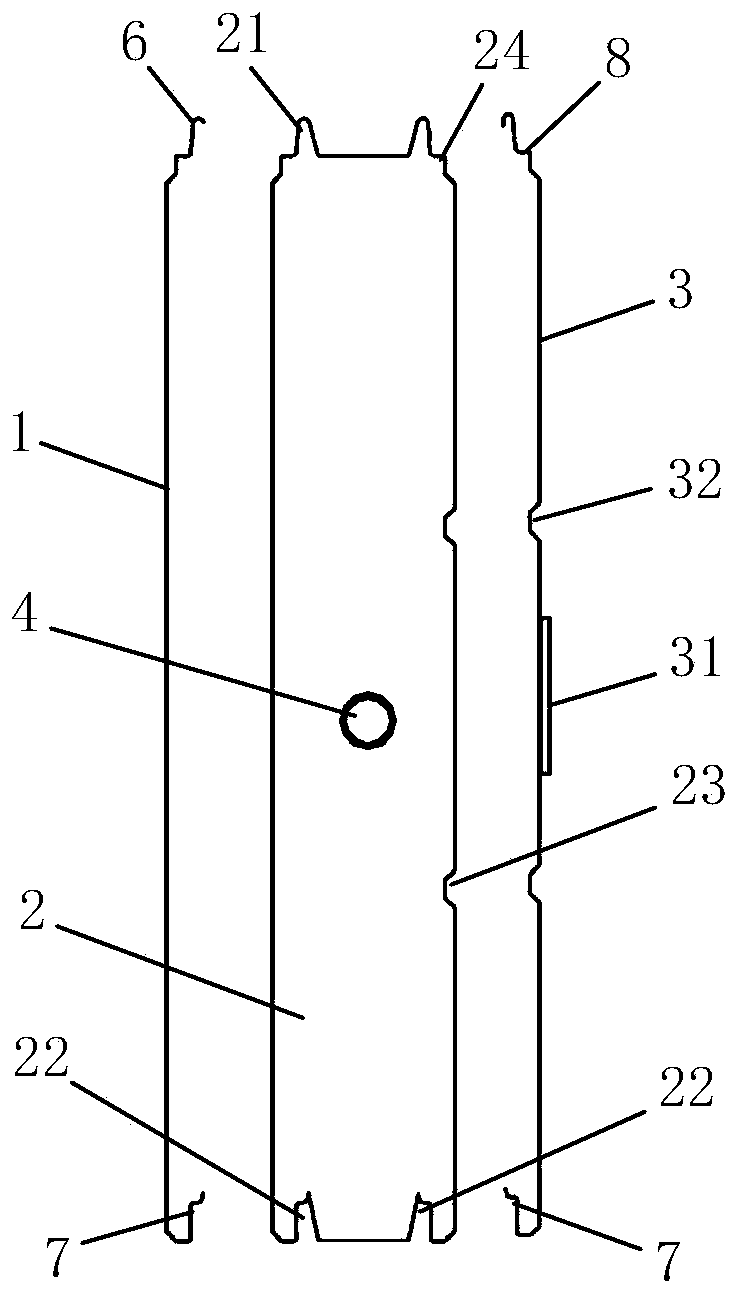

[0018] In this example, refer to figure 1 , figure 2 and image 3 , the modular wall panel structure is formed by sequentially plugging several wall panel unit modules A, each wall panel unit module A includes a polyurethane and ceramsite mixed foam 2 and a profiled plate, the profiled plate includes There are a first profiled plate 1 and a second profiled plate 3; the polyurethane and ceramsite mixed foam 2 is located in the middle, and the first profiled plate 1 and the second profiled plate 3 are respectively fastened and fixed on the polyurethane and ceramsite mixed The two side surfaces of the foam body 2; at least a switch / socket box 31 is provided in the second profiled plate 3, and a water and electricity installation pipe 4 is preset in the polyurethane and ceramsite mixed foam body 2; the upper and lower adjacent The wallboard unit modules A are respectively fixed by embedding and combining the concave-convex structures arranged on the upper and lower sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com