Stator-rotor double-permanent-magnet double-armature-winding magnetic field modulation permanent magnet motor structure

A double armature winding and armature winding technology, applied in the magnetic circuit shape/style/structure, electric components, magnetic circuit and other directions, can solve the problems of waste of space on the rotor side, poor reliability of torque output, and inability to generate torque. , to achieve the effect of improving torque density, high torque density, and strong fault tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

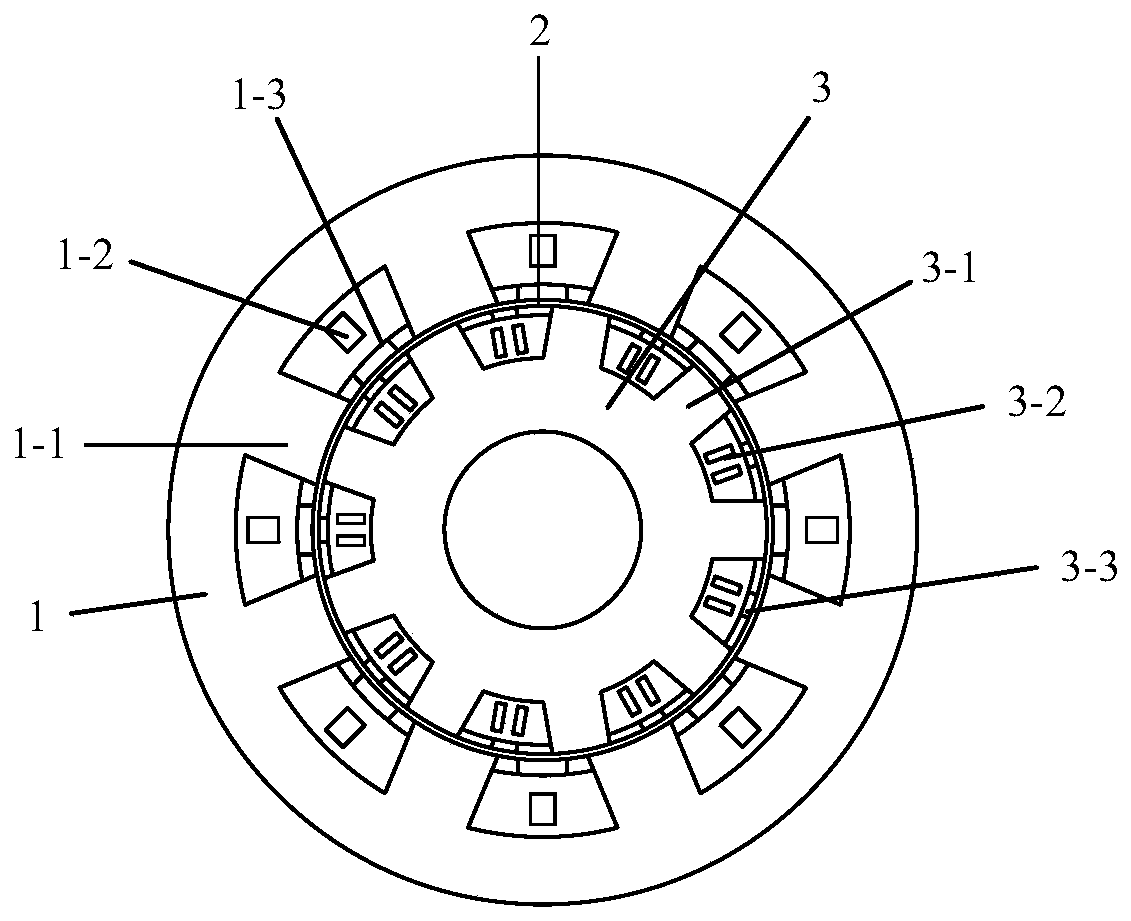

[0064] See figure 1 The present invention includes a stator 3, a rotor 1, an air gap 2 between the stator 3 and the rotor 1, the rotor 1 includes a rotor tooth 1-1, a rotor armature winding 1-2 and a rotor permanent magnet 1-3, and the stator 3 includes stator teeth 3-1. The stator armature winding 3-2 and the stator permanent magnet 3-3, the rotor armature winding 1-2 is wound on the rotor teeth 1-1 by two-phase armature winding, and the stator armature winding 3-2 is three The phase armature windings are wound on the stator teeth 3-1.

[0065] See figure 2 , figure 2 It is a star-shaped diagram of the stator winding of the present invention. The stator 3 of the present invention has 9 slots in total and adopts double-layer windings. The stator winding 3-2 is a three-phase distributed winding structure, which is fed with three-phase symmetrical alternating current to generate a pair of pole magnetic potential.

[0066] See image 3 , image 3 It is a star-shaped diagram of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com