Stirring structure for microbial fertilizer

A technology of a microbial fertilizer and a stirring mechanism, which is applied in the field of microorganisms, can solve the problems of clogging, low stirring efficiency and affecting work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

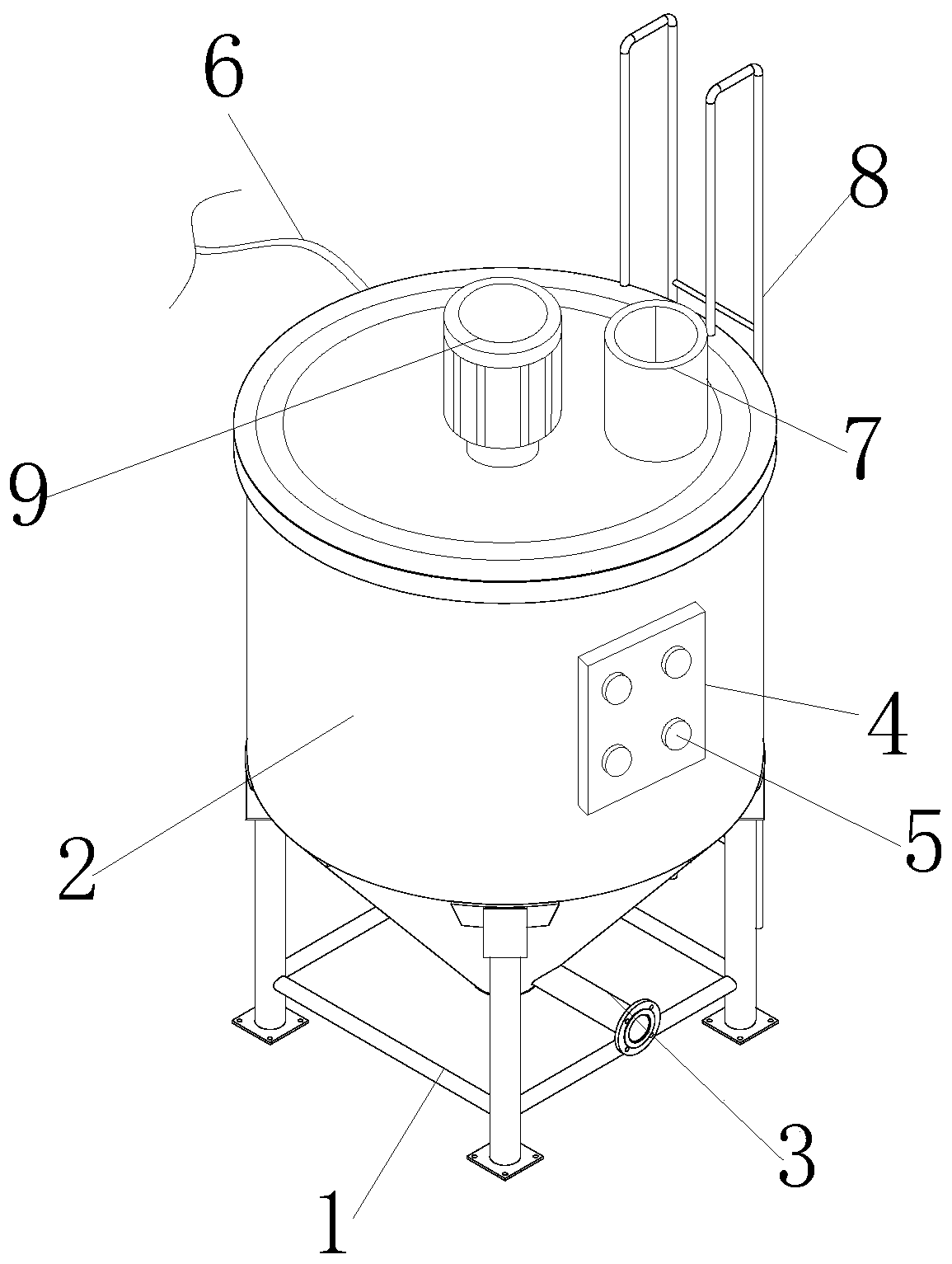

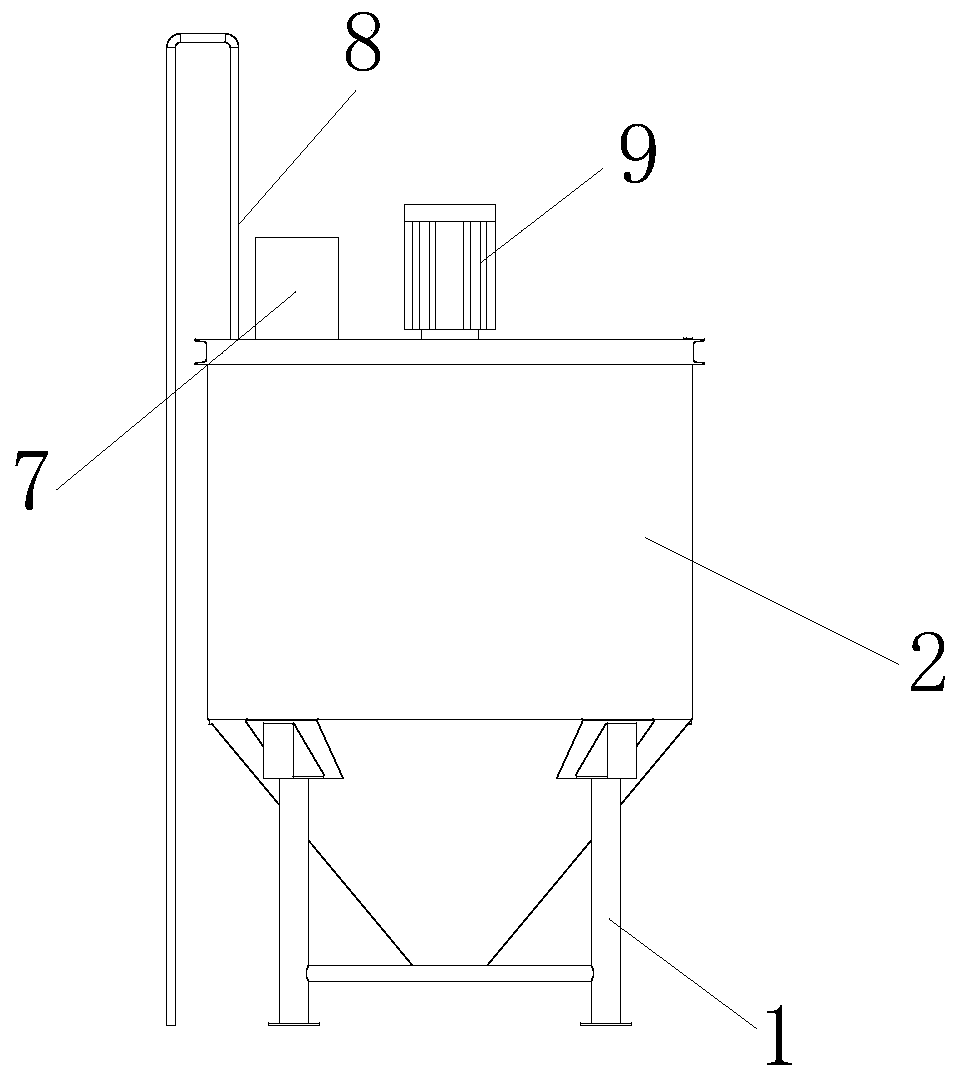

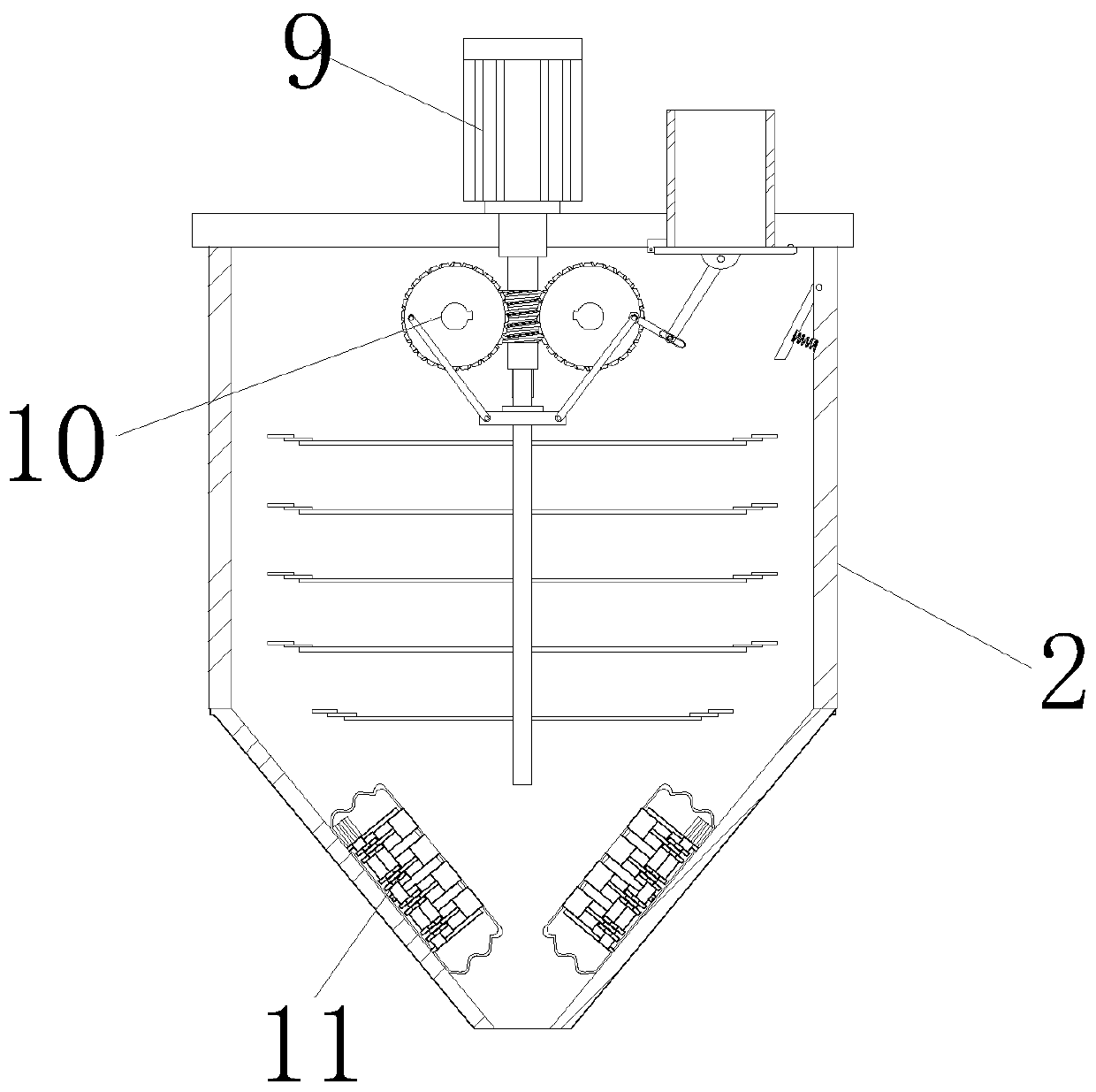

[0034] see figure 1 , figure 2 and image 3 , the present invention provides a kind of mixing structure that microbial fertilizer is used by improving here, comprises fixed frame 1, feeding hopper 7, escalator 8, first motor 9, lifting guide device 10 and auxiliary beating mechanism 11, and fixed frame 1 passes through Electric welding and the bottom of the stirring frame 2 are locked and fixed, the stirring frame 2 is connected to the left end of the discharge pipe 3, the right end of the stirring frame 2 is provided with a control panel 4, the front end of the control panel 4 is equipped with a button 5, and the lifting and deflecting device 10 is installed and fixed on the stirring frame 2. The inner upper end and the left end of the stirring frame 2 are fixed with a power wire 6. The stirring frame 2 is seamlessly connected with the bottom edge of the feeding hopper 7. The stirring frame 2 is fixedly connected to the front end of the escalator 8 by electric welding. The ...

Embodiment 2

[0041] The present invention provides a stirring structure for microbial fertilizers through improvement. The upper end of the first movable rod 1024 is provided with a chute 10241, and the second movable rod 1025 is slidably matched with the inner side of the chute 10241, and the upper end of the sealing plate 1021 is provided with a sealing protrusion. Block 10211, and the cross section of the sealing bump 10211 is semicircular, which is beneficial to play the role of sealing. The top of the beating head 117 is provided with a cushion pad 1171, and the cushion pad 1171 is seamlessly connected with the top of the beating head 117, which is conducive to buffering The upper end of the stirring shaft 1012 is provided with a sliding protrusion 10121, and there are two sliding protrusions 10121, which are located on the left and right sides of the upper end of the stirring shaft 1012, which is beneficial to make the stirring shaft 1012 rotate synchronously when lifting.

[0042] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com