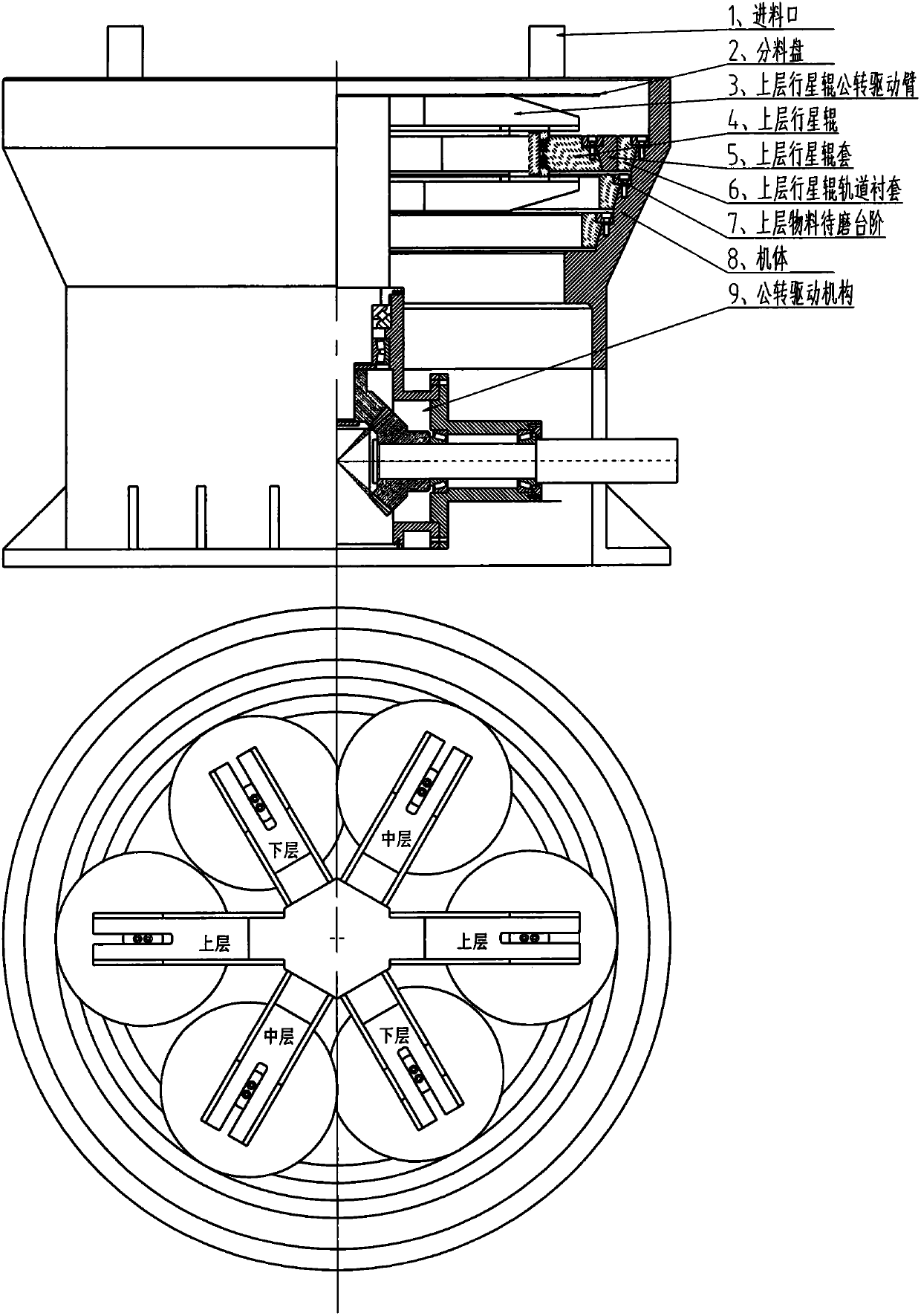

Planetary mill

A grinding machine and planetary technology, applied in the field of grinding machinery, can solve the problems of low grinding efficiency and high unit power consumption, and achieve the effects of improving grinding efficiency, long working cycle, and improving grinding probability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The object of the present invention is achieved in this way: the pre-crushed ore below 20mm enters the distribution tray through the feed port, the motor drives the planetary roller drive arm to rotate, drives the planetary roller to revolve and rotate, and synchronizes with the planetary roller drive arm The rotating distributing plate, under the action of centrifugal force, evenly distributes the material to the upper material to be ground. After being repeatedly rolled by the upper planetary roller, it overflows to the middle material to be grinded. After repeated rolling, it overflows to the lower stage where the material is to be ground. After repeated rolling by the lower planetary rollers, it overflows to the discharge port below, completing the grinding process. By controlling the feeding amount and the orbital angular velocity of the planetary rollers, the economic and technical indicators can be easily controlled. It can be equipped with an external high-effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com