Plastic thin film opening and flattening device and plastic thin film online side cutting and flattening method

A plastic film and film technology, which is applied in the field of plastic film stretching and flattening devices, can solve the problems of film rolling and wrinkling, and achieve the effects of reducing friction, avoiding secondary processing, and having obvious guiding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

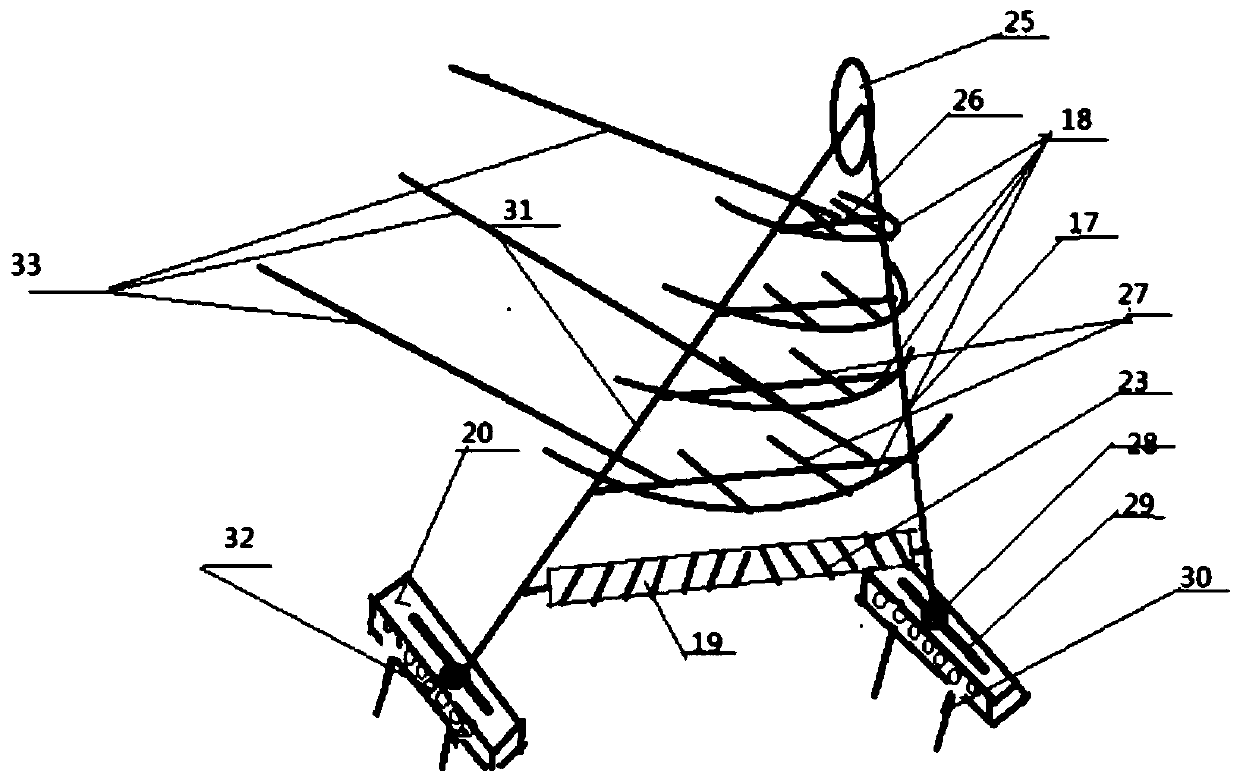

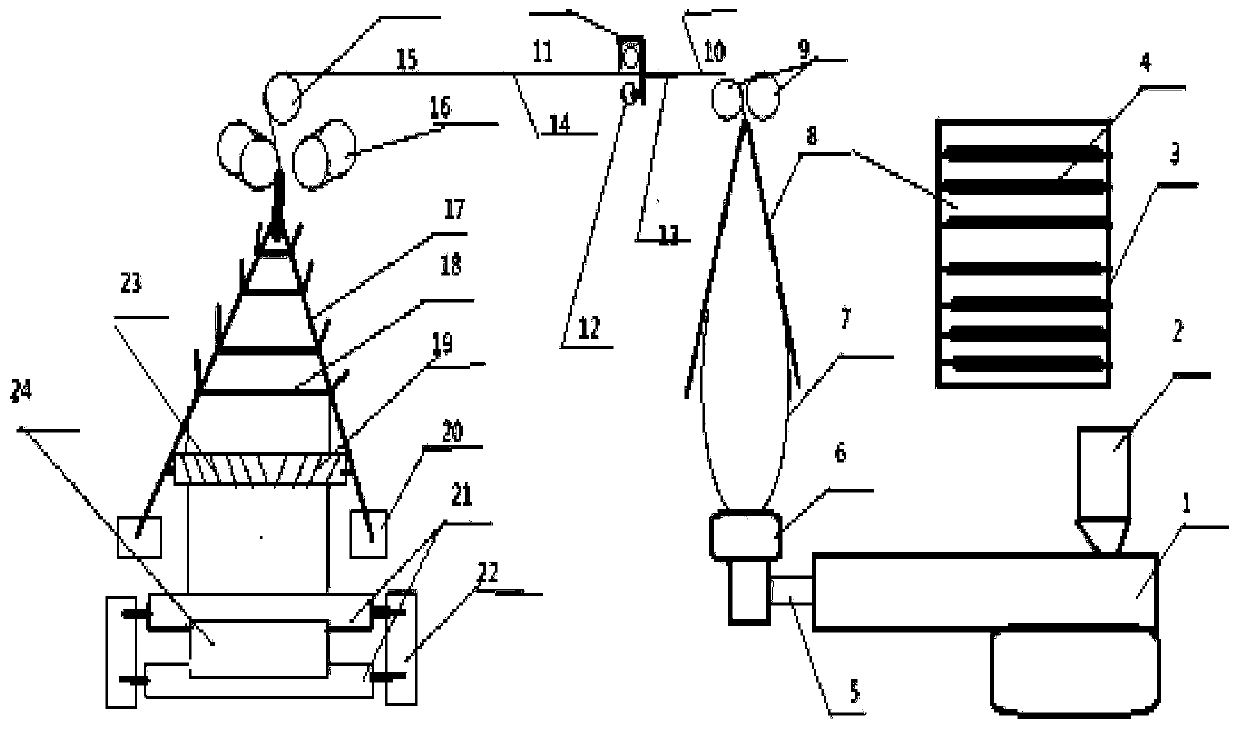

[0064] There are four crossbeams in the film flattening mechanism, and three leading screws are arranged, and the three leading screws are connected with the upper and lower crossbeams respectively, and the other end of the leading screw is connected with the auxiliary frame.

[0065] The online side section flattening method of plastic film is:

[0066] The first step is to put the raw materials into the hopper, heat, plasticize and melt them through the extruder, and then enter the mold, extrude the ring-shaped blank in the ring-shaped forming section of the mold, and fill the blank with compressed air to form a film bubble;

[0067] The second step is to introduce the film bubble into the splint and enter the traction roller, and form a cylindrical film after extrusion;

[0068] The third step is to slide on the horizontal sliding bar through the knife holder chute with the knife. The knife cuts one side of the tubular film into a single piece of film, and the single piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com