A kind of anti-wind and wave dredging pipe for water conservancy construction

A wind and wave resistance and water conservancy technology, applied in water conservancy projects, water conservancy engineering equipment, instruments, etc., can solve the problems that dredging pipes are vulnerable to wind and wave impact and wear, and achieve the effects of avoiding wear, prolonging service life and reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

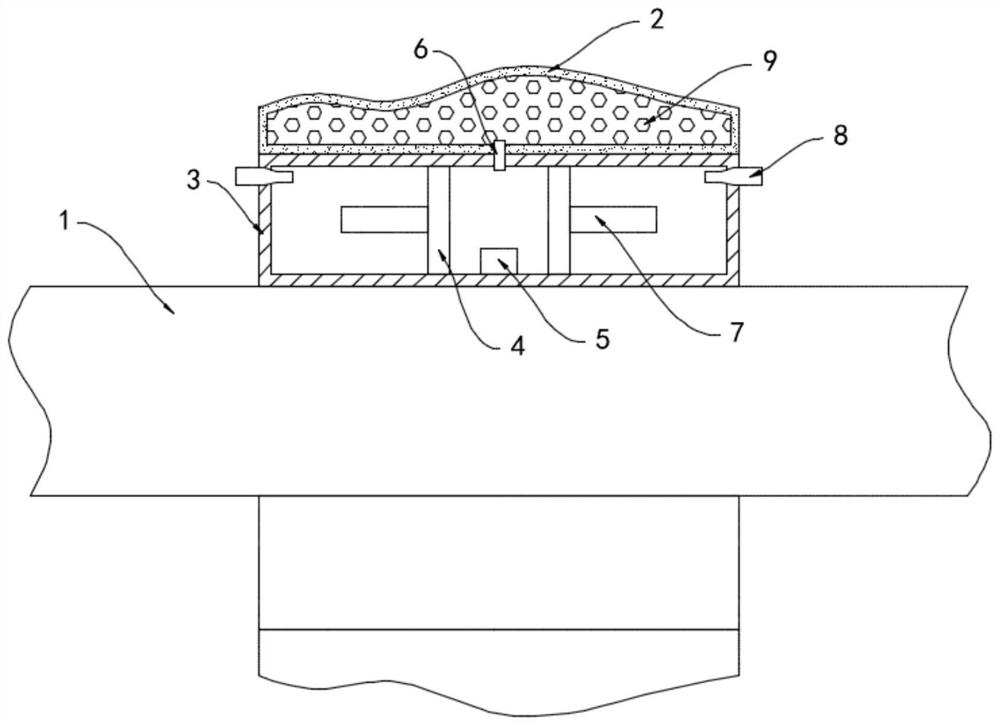

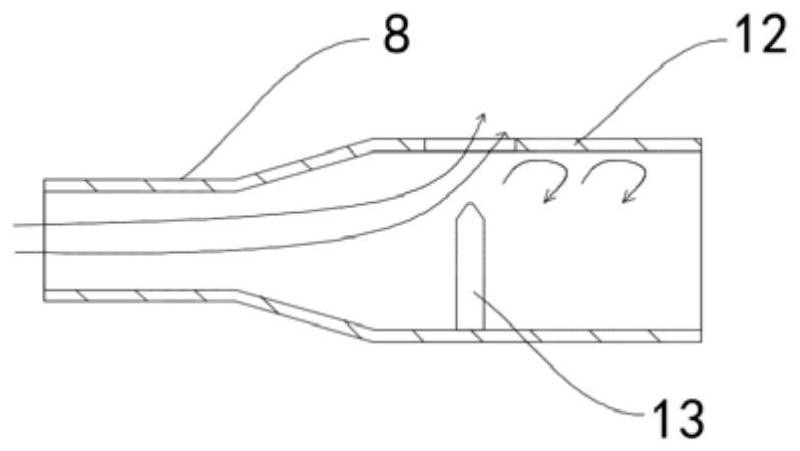

[0019] like Figure 1-2 As shown, an anti-wind and wave dredging pipe for water conservancy construction includes a pipe body 1 and an annular floating body fixedly sleeved on the outside of the pipe body 1. The annular floating body is composed of a deformation bag 2 and a fixed box 3, wherein the deformation bag 2 is sleeved on the fixed body. Outside the box 3, the deformation box 3 and the pipe body can be fixedly connected by welding, the deformation bag 2 is made of elastic rubber material, and the deformation bag 2 is filled with elastic balls 9, which can play a good supporting role. To prevent excessive deformation of the deformation capsule 2 due to the excessive impact force of the waves, the internal wear of the deformation capsule 2 is reduced, and the wind and wave resistance of the deformation capsule 2 is further improved. 4. There is a limit block 5 between the two slip rings 4, the limit block 5 is fixedly connected to the inner side wall of the fixed box 3, ...

Embodiment 2

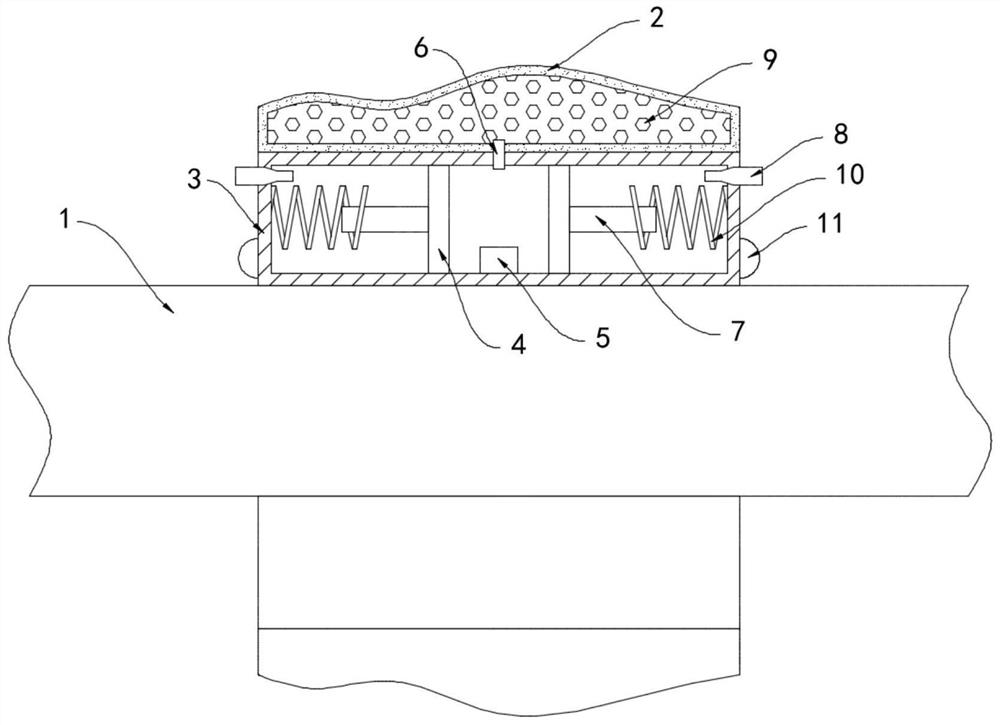

[0024] like image 3 As shown, the difference between this embodiment and Embodiment 1 is that an electromagnetic spring 10 is installed in the fixed box 3, the electromagnetic spring 10 is sleeved outside the permanent magnet column 7, and an LED light 11 is installed outside the fixed box 3, and the LED light 11 is electrically connected to both ends of the electromagnetic spring 10 to form a closed loop.

[0025] In this embodiment, the deformation capsule 2 is deformed by the impact of wind and waves, and the air pressure drives the two permanent magnet columns 7 away from each other. Because the farther the two permanent magnet columns 7 are, the smaller the magnetic attraction force is. 7 After the distance is far, the attractive force between them cannot offset the impact force of the waves. At this time, the permanent magnet column 7 is close to the electromagnetic spring 10. According to the distance from the electromagnetic induction, the electromagnetic spring 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com