Energy-saving glass pumice concrete building block hole type

A technology of concrete block and glass pumice stone, which is applied in the fields of climate change adaptation, building components, thermal insulation, etc. resistance and other problems, to achieve the effect of improving thermal insulation capacity, simple structure and reducing cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

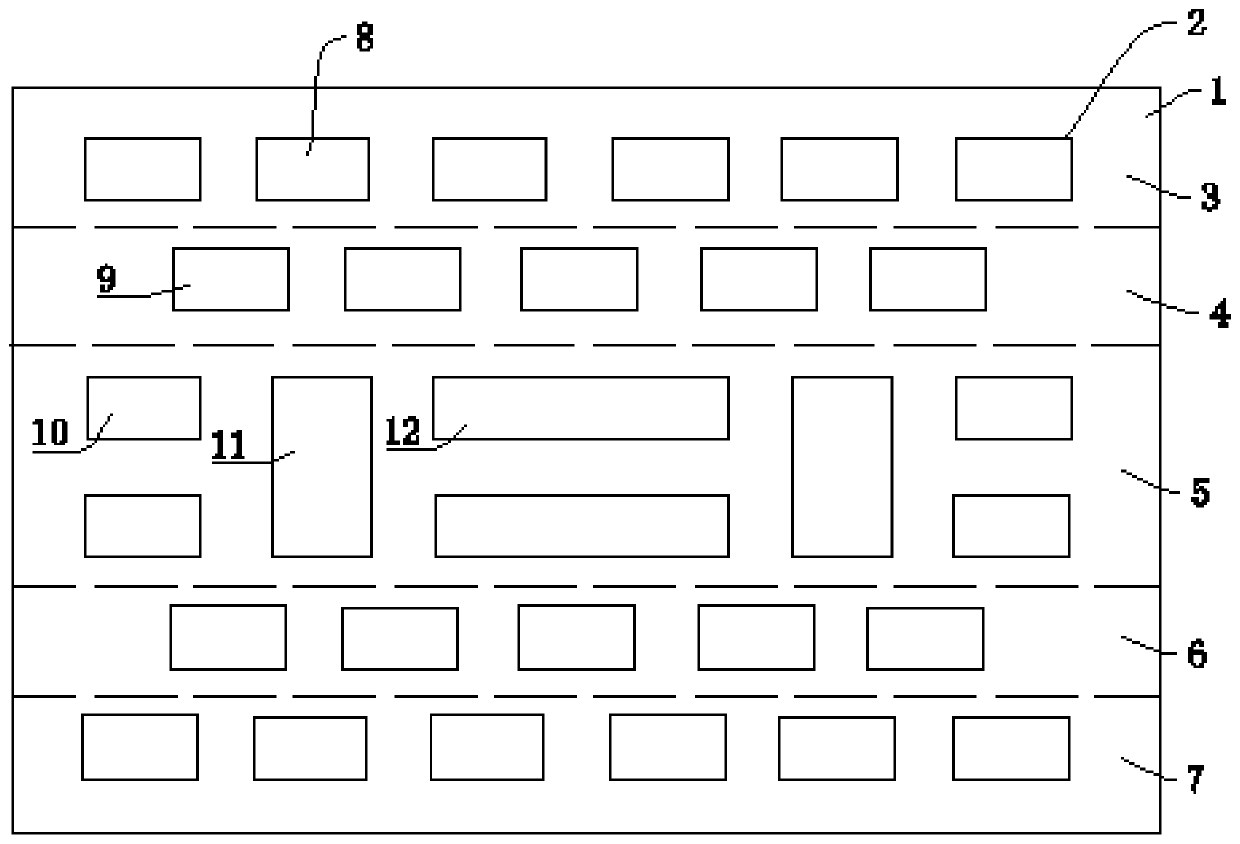

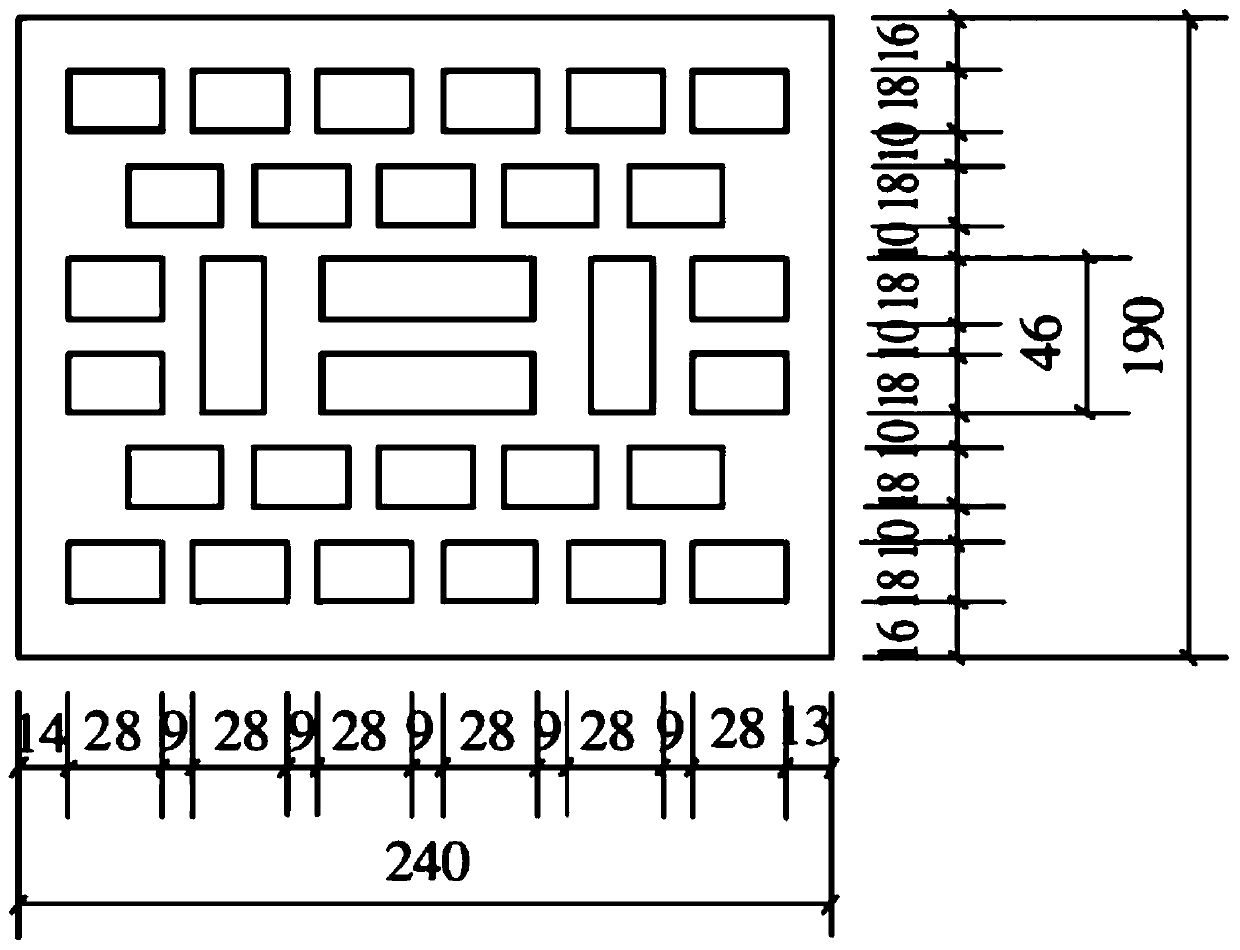

[0019] Embodiment 1: An energy-saving glass pumice concrete block 1 hole type, such as figure 1 , figure 2 As shown, the size of the block is 240mm×190mm×90mm, and there are five layers of holes 2 distributed on the block 1, which are A layer 3, B layer 4, C layer 5, D layer 6, and E layer 7 from top to bottom. , the holes 2 in each layer are distributed in a staggered manner, and the shapes of the holes 2 are all rectangular or "T". The structure in layer 3 is the same as that in E layer 7, and the structure in B layer 4 is the same as that in D layer 6.

[0020] Such as figure 1 , figure 2 As shown, the layer A 3 includes six groups of first holes 8 arranged in parallel, and the size specification of the first holes 8 is 28*18mm 2 The distance between the first holes 8 is 9 mm, the distance between the A layer 3 and the top of the block 1 is 16 mm, and the distance between the first holes 8 and the left and right borders of the block 1 is 14 mm.

[0021] Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com