Waterproof roll mounting structure and waterproof roll mounting method

A technology of waterproofing membrane and installation structure, which is applied in building construction, roofing with flexible materials, snow traps, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

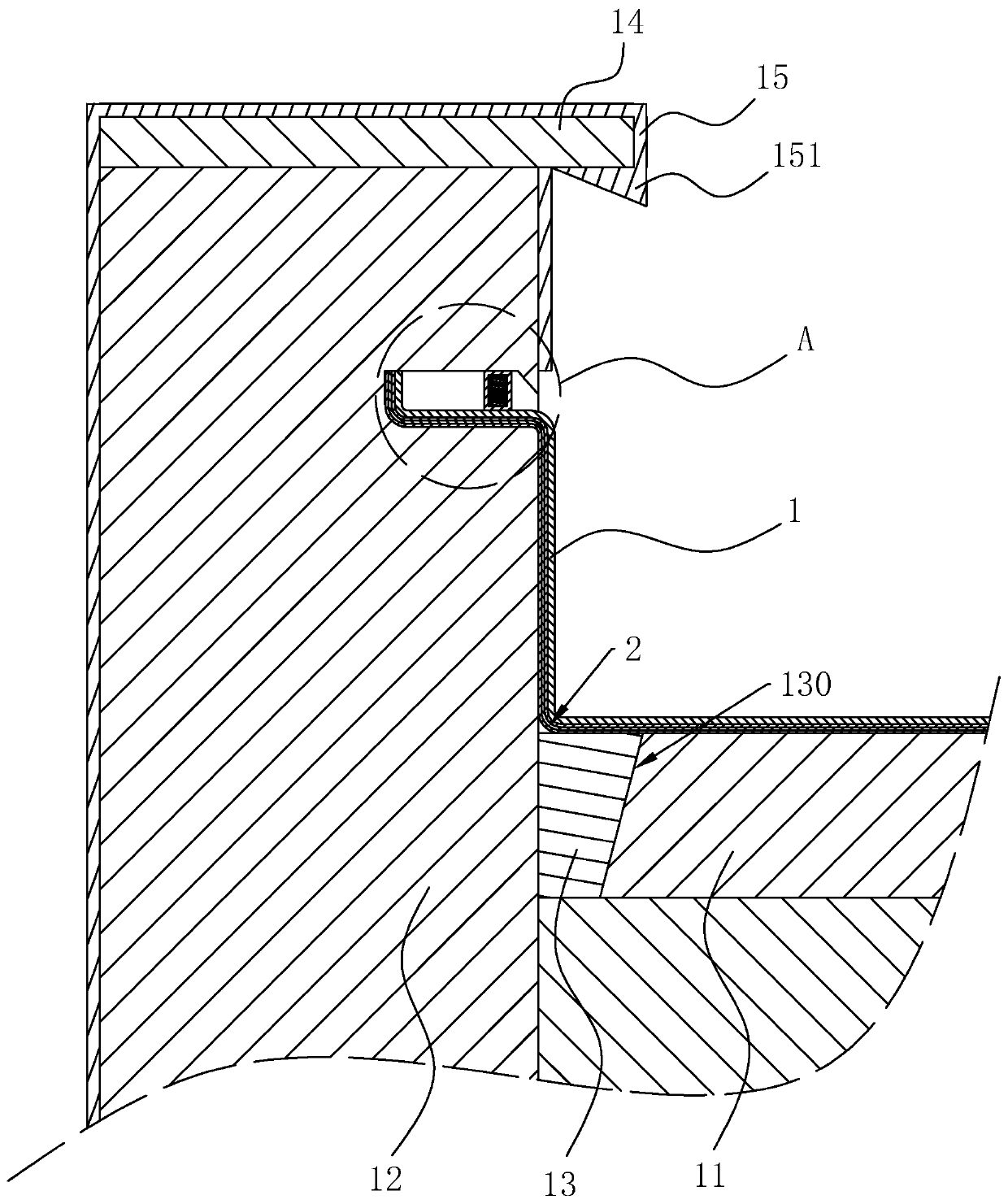

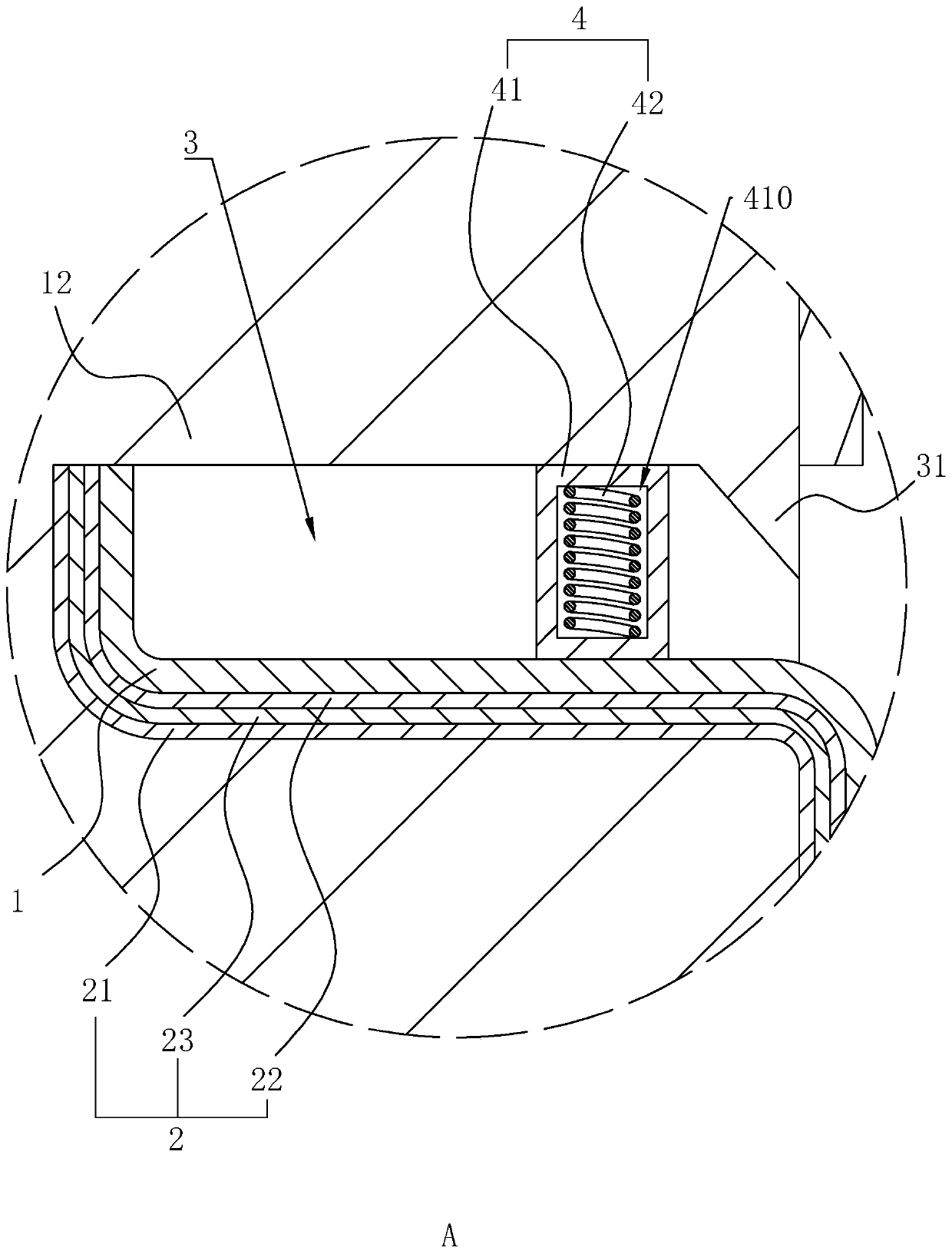

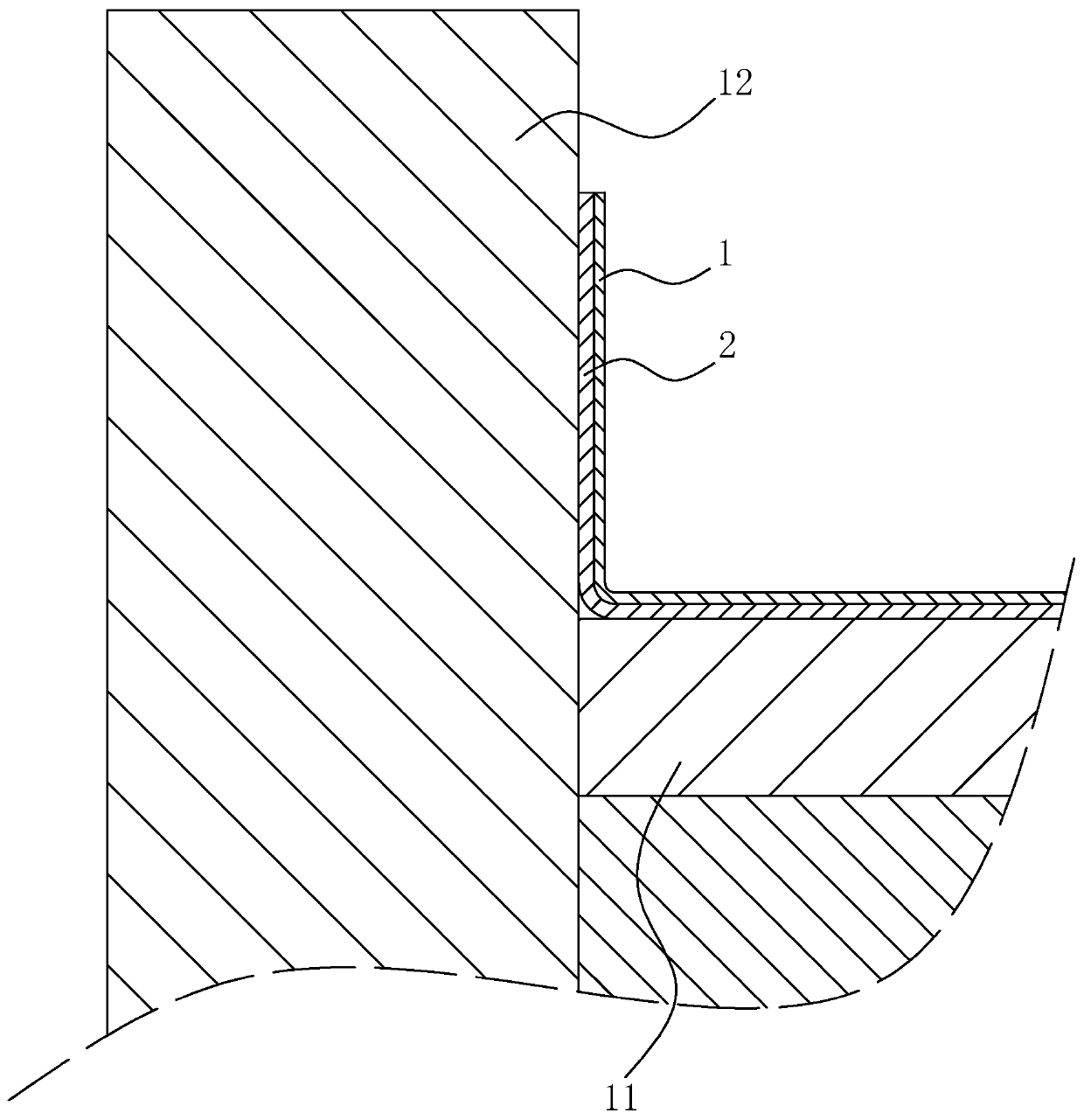

[0043] A waterproof membrane installation structure, refer to figure 1 , which includes a roof panel 11, an outer wall 12, a glue layer 2 and a waterproof membrane 1. The outer wall 12 is vertically arranged, the roof panel 11 is positioned at the inner side of the outer wall 12, and the waterproof coiled material 1 is provided at the corner of the top wall of the roof panel 11 and the inner side wall of the outer wall 12, and the inner side of the waterproof coiled material 1 is connected with the roof panel 11 top wall and the outer wall. A glue layer 2 is arranged between the corners of the inner wall of the wall 12, and the glue layer 2 is formed by drying after applying glue. The two ends of the waterproof coiled material 1 are respectively connected to the inner side wall of the outer wall 12 and the top wall of the roof panel 11 through the glue layer 2 . A gap is reserved between the outer wall 12 and the roof panel 11 to form a reserved groove 130, and the reserved ...

Embodiment 2

[0050] A method for installing waterproof membranes, comprising the steps of:

[0051] S1. Use a vacuum cleaner to clean the top wall of the roof panel 11 and the side wall of the outer wall 12 to remove floating ash and gravel.

[0052] S2. Apply glue on the top wall of the roof panel 11 and the side wall of the outer wall 12 to form the first base layer of glue 21, dry it for later use, and apply glue on the inner wall of the waterproof coiled material 1 to form the second base layer of glue 22, dry it for later use , When applying glue, ensure that the thickness is uniform, and there must be no exposed bottom or gelatinous blocks.

[0053] S3, apply glue on the outside of the first base layer of adhesive layer 21 to form the connecting adhesive layer 23, lay the inner side of the waterproof coiled material 1 on the surface of the connecting adhesive layer 23, and make the top of the waterproof coiled material 1 extend into the waterproof groove 3, and The top of the waterp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com