An Inverted Bucket Trap to Prevent Flash Leakage

A technology of trap and upside-down, applied in steam traps, mechanical equipment, etc., can solve problems such as unfavorable energy saving and emission reduction, and achieve the effect of preventing rapid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

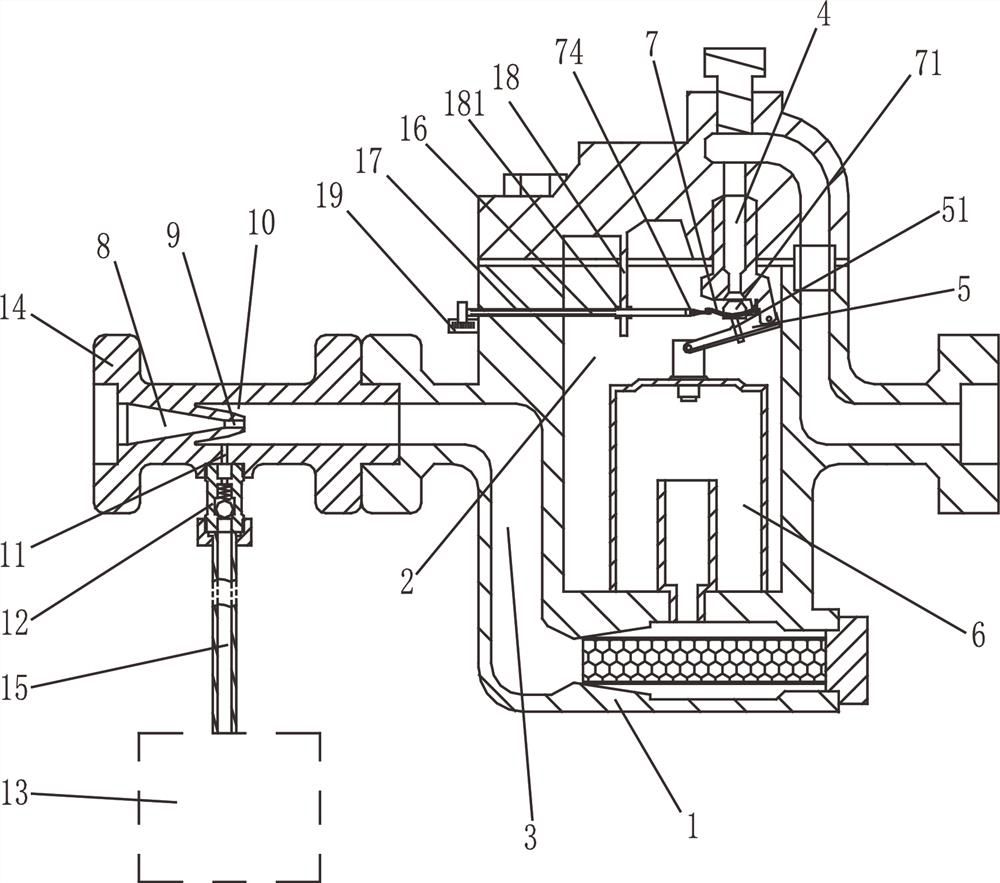

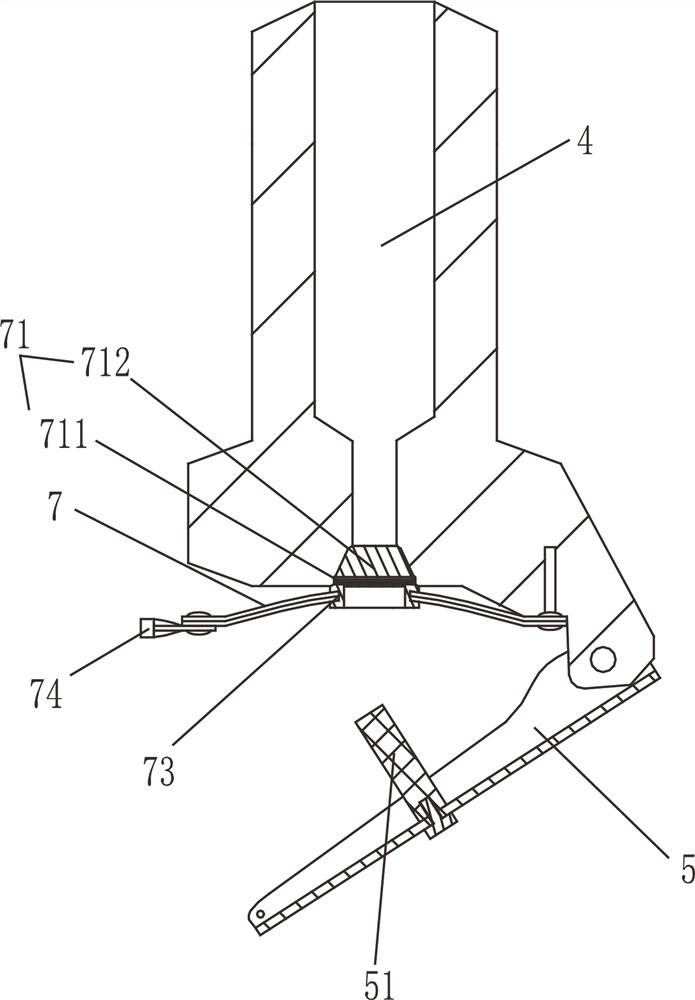

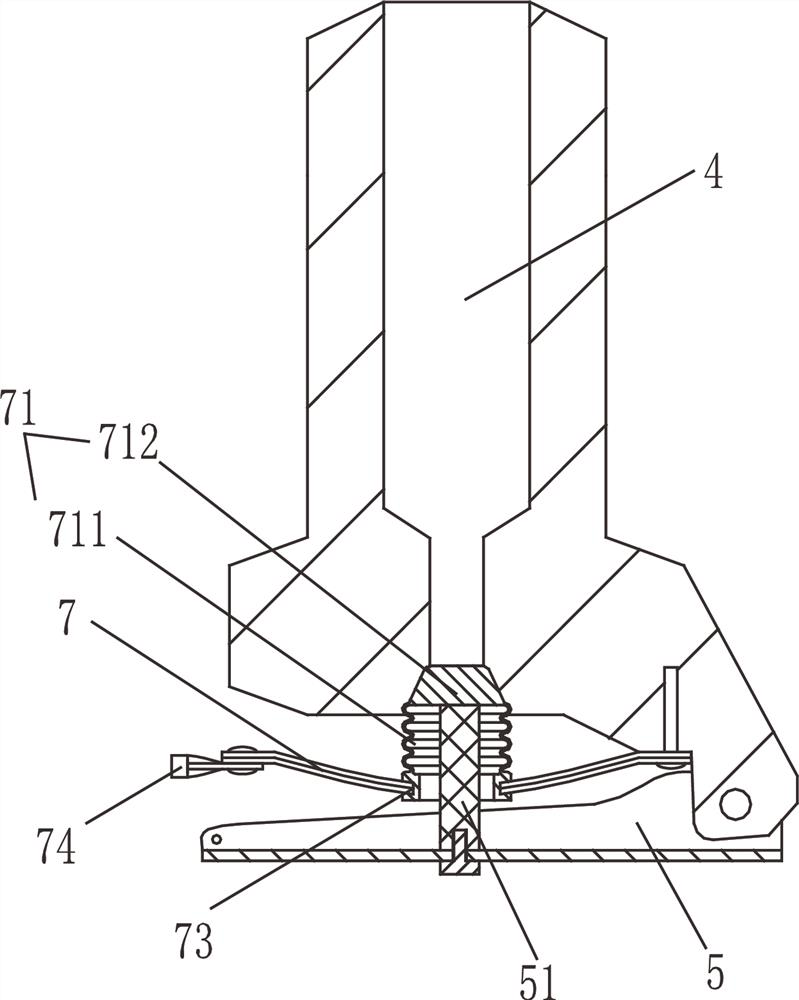

[0017] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 3 , an inverted bucket trap for preventing flash leakage, comprising a valve body 1, a gas-liquid separation chamber 2, a steam inlet channel 3 and a liquid outlet channel 4 are arranged on the valve body 1, and a rotating arm is arranged at the bottom of the liquid outlet channel 4 5. The rotating arm 5 is rotatably connected with an inverted bucket 6. The inverted bucket 6 is covered on the steam inlet channel 3. There is an arc-shaped heat-sensitive bimetal sheet 7 between the liquid outlet channel 4 and the rotating arm 5. The arc-shaped heat-sensitive bimetal The sheet 7 is provided with a spool 71 that can block the liquid outlet channel 4 after a sudden jump in temperature. One end of the arc-shaped heat-sensitive bimetallic sheet 7 is fixed by a screw, and the other end is connected with an adjusting sleeve 74, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com