Antistatic foamed silica gel plate composition and production method of foamed silica gel plate

A foamed silica gel plate and production method technology, applied in the direction of conductive paint, coating, etc., can solve problems such as prone to electrostatic accumulation, and achieve the effects of facilitating corona discharge, preventing local accumulation, and good lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

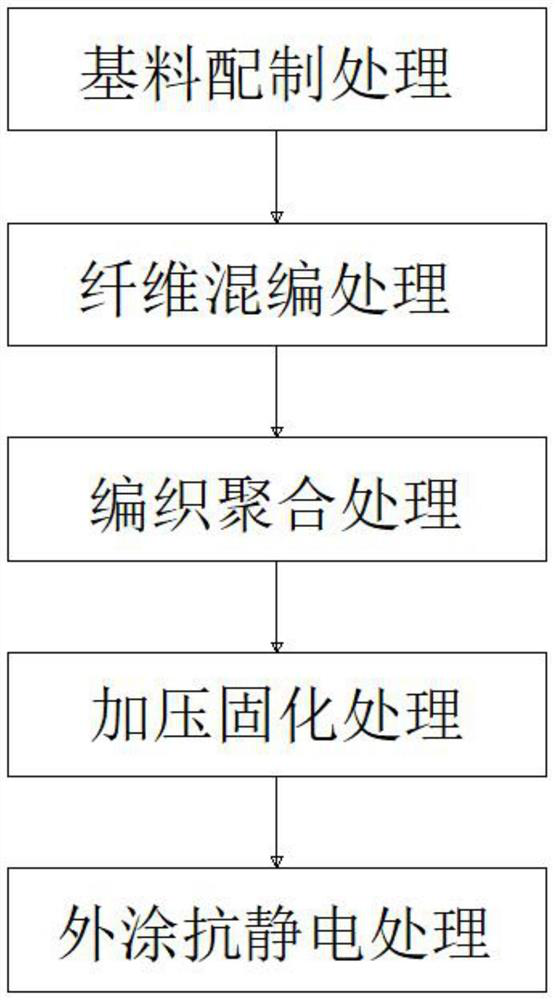

[0055] Such as figure 1 Shown, a kind of antistatic foamed silicone plate composition, it comprises by weight:

[0056] Silicone rubber 80 parts

[0057] Foaming agent 4 parts

[0058] Vulcanizing agent 2 parts

[0059] External coating antistatic agent 4 parts

[0060] 5 parts of internal mixed antistatic agent

[0061] Discharge fiber 5 parts

[0062] The composition and the ratio of described whipping agent are by weight:

[0063] Azobisisobutyronitrile 40 parts

[0064] Methyl vinyl silicone rubber 40 parts

[0065] Vinyl silicone oil 20 parts

[0066] The composition and the ratio of the vulcanizing agent are by weight:

[0067] 50 parts of dibenzoyl peroxide

[0068] Methyl vinyl silicone rubber 50 parts

[0069] The composition and ratio of the external coating type antistatic agent are by weight:

[0070] 40 parts of alkyl quaternary ammonium salt

[0071] Chloride 40 parts

[0072] 20 parts of resin glue

[0073] The composition and ratio of the internal ...

Embodiment 2

[0084] Such as figure 1 Shown, a kind of antistatic foamed silica gel plate composition and foamed silica gel plate production method, it comprises by weight:

[0085] Silicone rubber 90 parts

[0086] Foaming agent 3 parts

[0087] Vulcanizing agent 1 part

[0088] External coating antistatic agent 2 parts

[0089] 2 parts of internal mixed antistatic agent

[0090] Discharge fiber 2 parts

[0091] The composition and the ratio of described whipping agent are by weight:

[0092] Azobisisobutyronitrile 60 parts

[0093] Methyl vinyl silicone rubber 25 parts

[0094] Vinyl silicone oil 15 parts

[0095] The composition and the ratio of the vulcanizing agent are by weight:

[0096] 70 parts of dibenzoyl peroxide

[0097] Methyl vinyl silicone rubber 30 parts

[0098] The composition and ratio of the external coating type antistatic agent are by weight:

[0099] 60 parts of alkyl quaternary ammonium salt

[0100] Chloride 30 parts

[0101] 10 parts resin glue

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com