Optimal control system for lng filling station

A technology of optimized control and station control system, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of liquid injection machine not working, stop valve closing slowly, large leakage, etc., to ensure safety , to ensure automation, to ensure the effect of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] 1. All functions of the station control system are controlled by DCS, and the redundant design of the system ensures the safe and stable operation of the device;

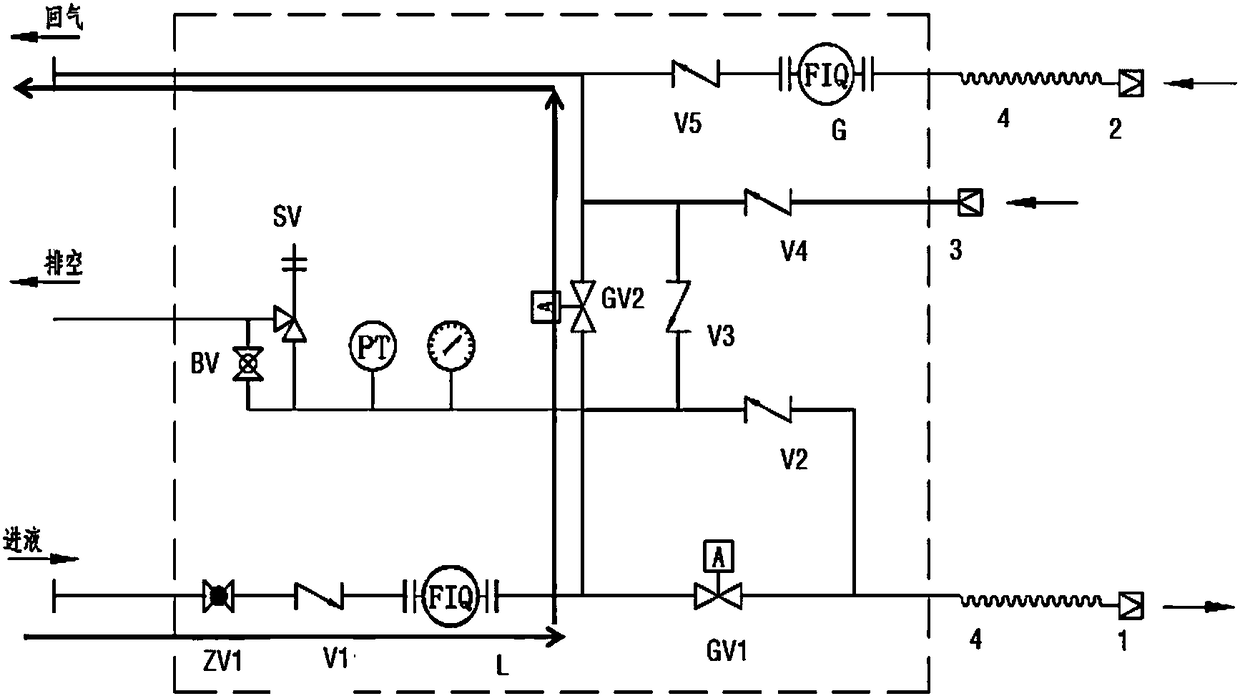

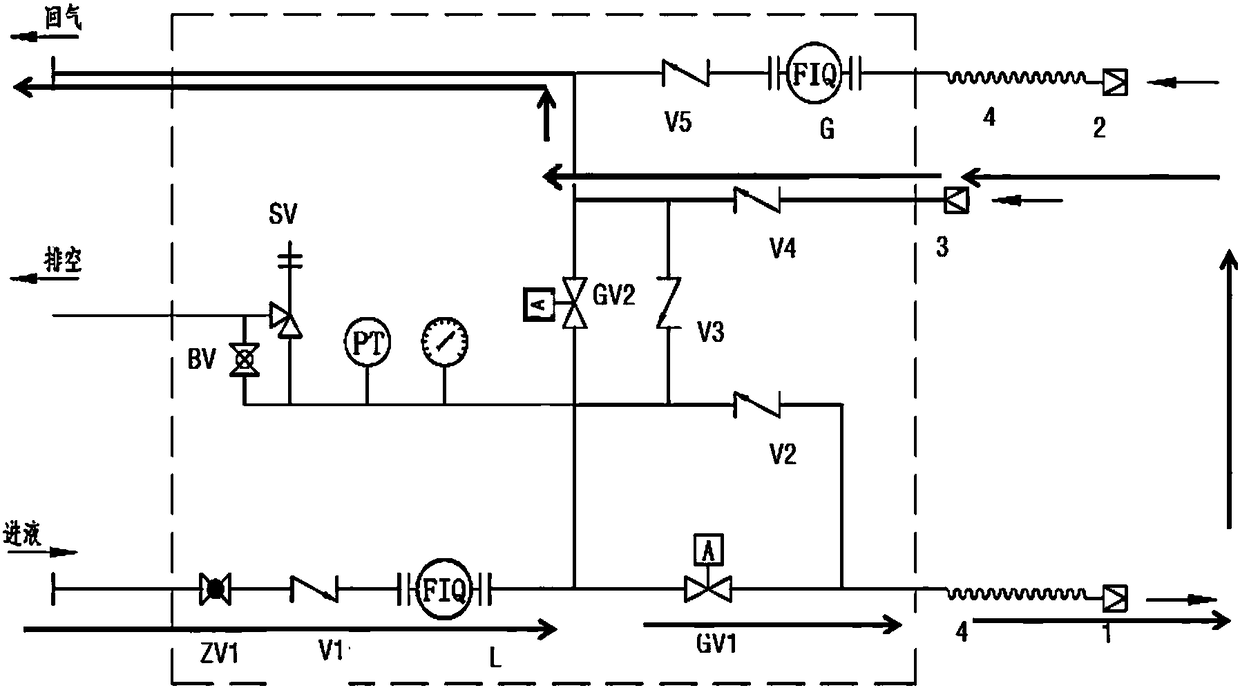

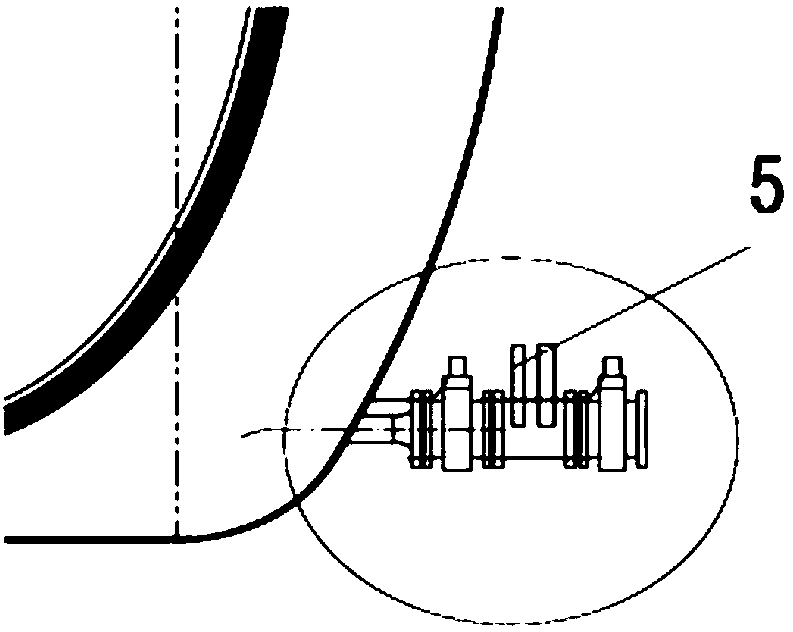

[0029] Figure 1-2 Among them, V1-5 is one-way valve 1-5, GV1-2 is pneumatic valve 1-2; L, Q(FIQ) are liquid phase mass flowmeter and gas phase mass flowmeter respectively; BV is ball valve; SV is safety valve ; ZV1 is the cut-off valve, liquid filling gun head 1, air return gun head 2, gun insertion port 3, metal hose 4; thermocouple gauge and cold cathode gauge 5.

[0030] At present, LNG sub-stations are batch controllers and station control systems on liquid injection machines or gas dispensers. Most of the batch controllers are Siemens S200 system; the valves (inlet valve, return valve, exhaust valve) and instruments (quality, pressure, temperature) in the liquid injection machine are directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com