Sampling equipment for geological detection

A sampling equipment and geological technology, applied in the direction of sampling devices, etc., can solve problems affecting the accuracy of detection results, inaccurate sampling, soil sample confusion, etc., and achieve the effects of convenient control of water sample collection, reduction of manufacturing costs, and reduction of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

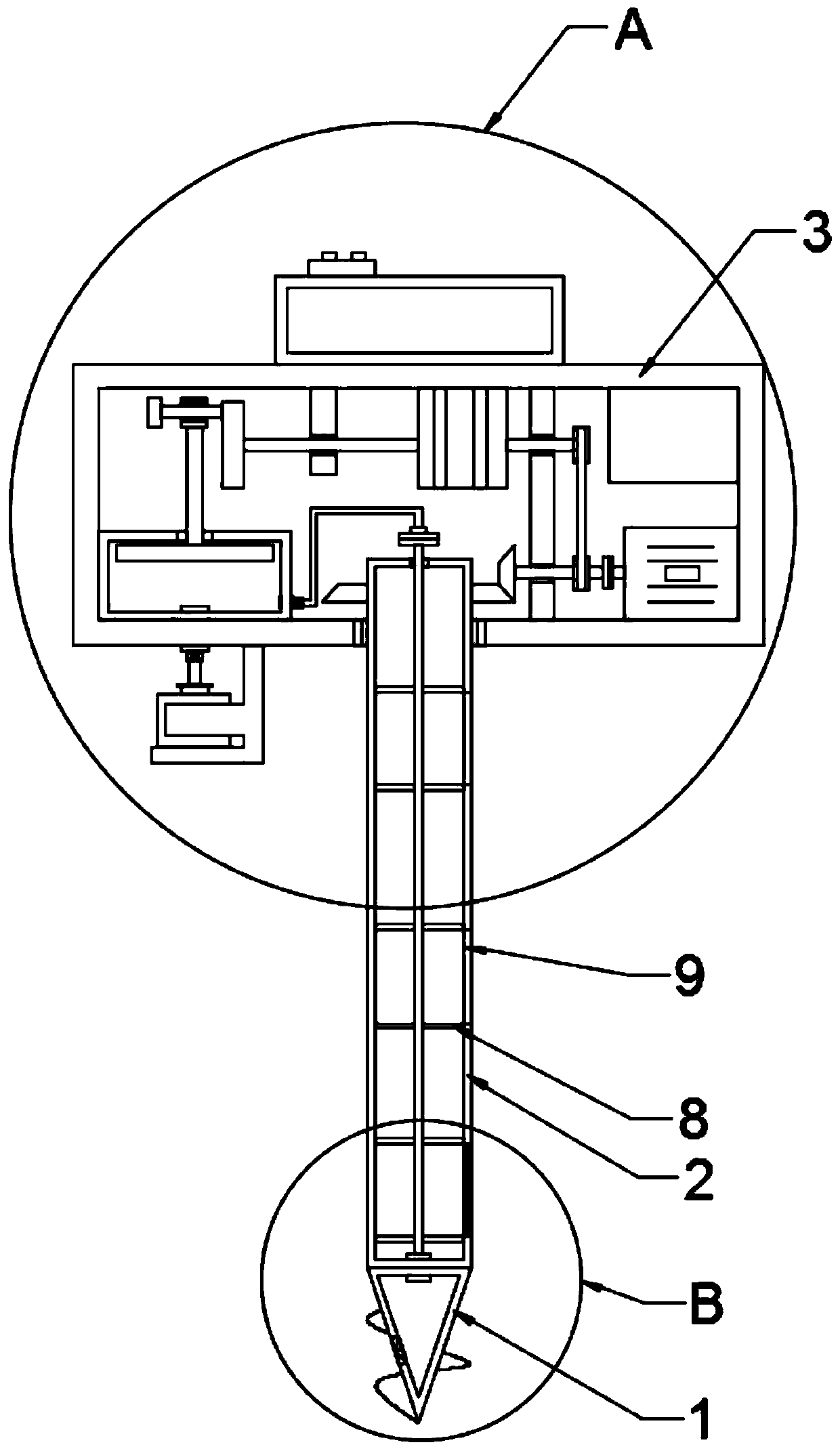

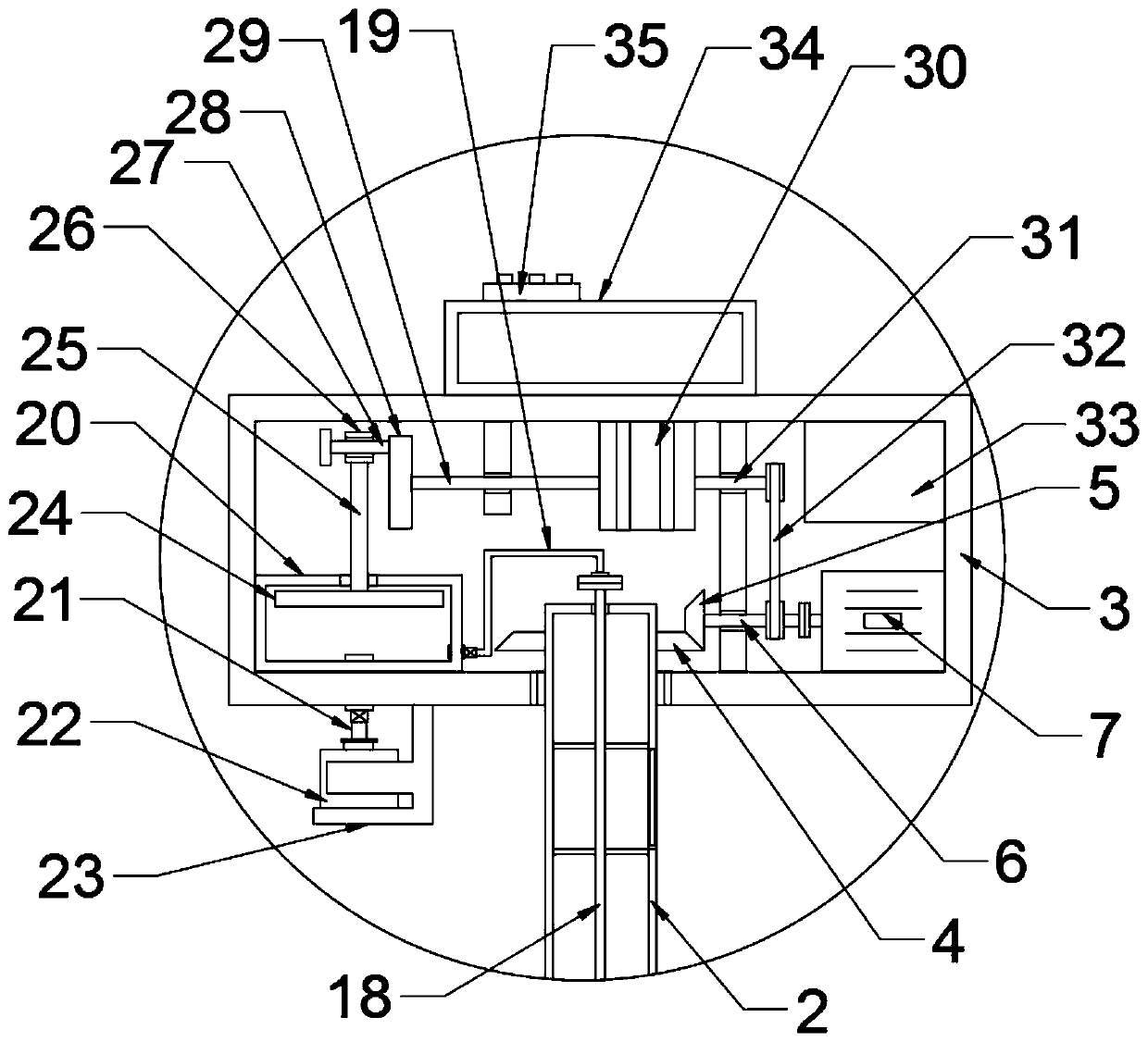

[0021] See Figure 1-5 In an embodiment of the present invention, a sampling device for geological inspection includes an equipment body; the equipment body includes a drill bit 1 and a drill barrel 2; the upper end of the drill bit 1 is fixedly connected with a drill barrel 2, and the upper end of the drill barrel 2 is connected with a drive Device, the drill barrel 2 is nested with a plurality of sampling barrels 8 distributed equidistantly, the sampling barrel 8 is a cylindrical barrel, and the side wall of the sampling barrel 8 is provided with a fan-shaped through groove 9 which communicates with the outside atmosphere, and the fan-shaped through groove 9 is nested with an outer scraper 10, the end of the outer scraper 10 is hinged with the inner wall of the fan-shaped through slot 9 through the first hinge seat 12, the hinge shaft of the first hinge seat 12 is sleeved with a torsion spring 13, and one end of the torsion spring 13 is connected with The outer scraper 10 abu...

Embodiment 2

[0024] The difference between this embodiment and the first embodiment is: after scraping the soil, the drill barrel 2 rotates in the opposite direction to achieve the rapid lifting of the drill barrel 2. When the sampling barrel 8 on the upper part of the drill barrel 2 is separated from the drilling pit on the ground, the lower part The sampling barrel 8 is still in the drilling pit. If the drilling barrel continues to rotate at this time, under the action of centrifugal force, the soil in the upper sampling barrel 8 is squeezed by the external scraper 10, which may cause the soil to be completely thrown out of the sampling barrel 8, causing soil In order to solve the above problem; the inner side of the outer scraper 10 is provided with an inner hinge plate 14, the end of the inner hinge plate 14 is hinged with the inner wall of the fan-shaped through groove 9 through the second hinge seat 15, and the inner wall of the sampling cylinder 8 is provided with an inner wall The li...

Embodiment 3

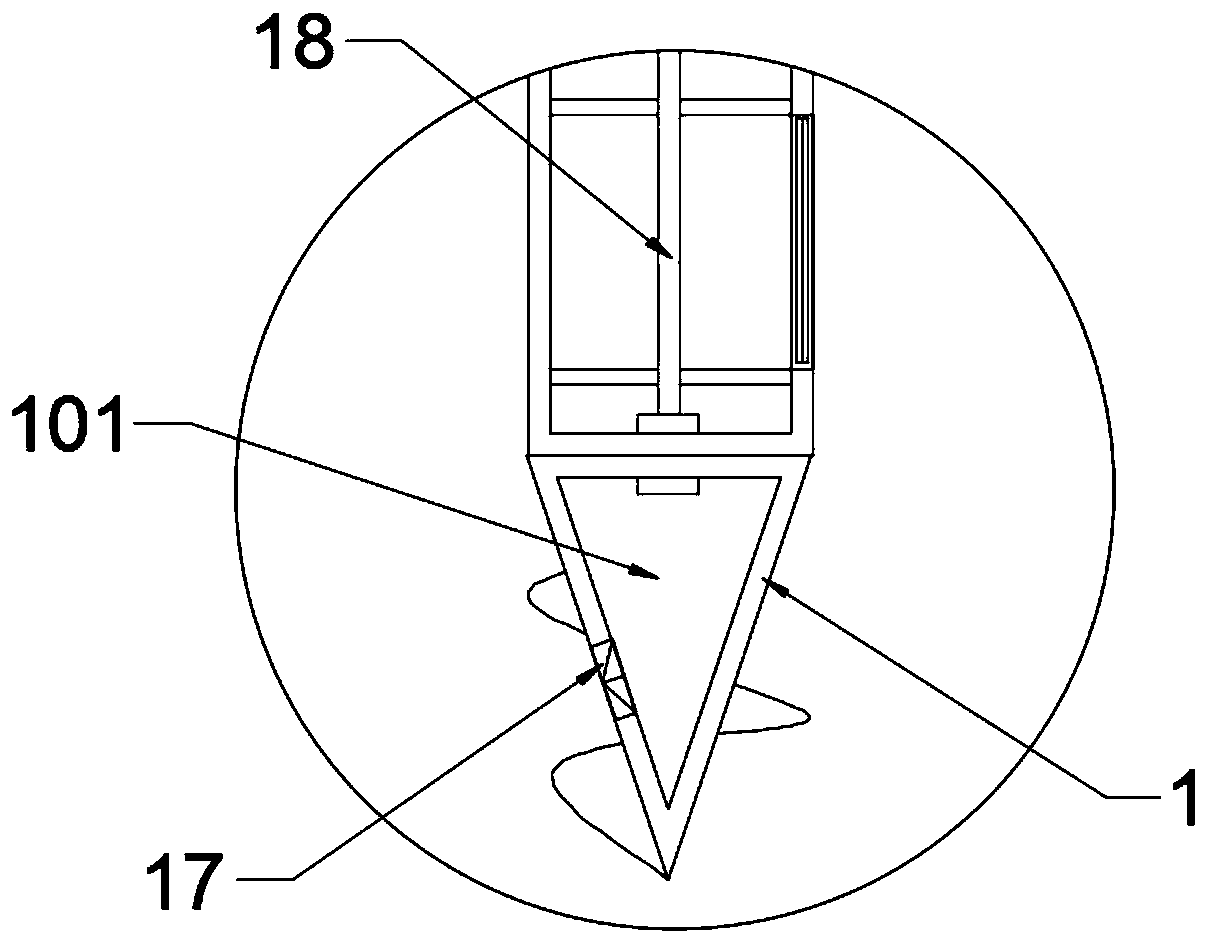

[0026] The difference between this embodiment and the second embodiment is that: in order to achieve the collection of water samples in the soil at a specified depth; the drill bit 1 is provided with a pumping cavity 101, the side wall of the drill bit 1 is provided with a pumping hole 17, and the pumping hole 17 is nested There is a filter; the pumping cavity 101 is connected with a pumping pipe 18, which penetrates the drill barrel 2 and extends to the top of the drill barrel 2, the pumping pipe 18 is connected with a water inlet pipe 19 through a rotary joint, and the water inlet pipe 19 is connected with a pumping mechanism, The pumping mechanism performs pumping operations through the pumping pipe 19, the pumping cavity 101, and the pumping hole 17, and collects water samples.

[0027] The pumping mechanism includes a pumping cylinder 20 communicating with a water inlet pipe 19, and a first check valve is provided at the place where the water inlet pipe 19 communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com