Combined control device based on green medium

A control device and combined technology, applied in the direction of fluid pressure actuating device, servo motor assembly, fluid pressure actuating system assembly, etc., can solve the problems of pollution and medium failure, and achieve good environmental protection, perfect function and strong practicality. Sexual and generic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

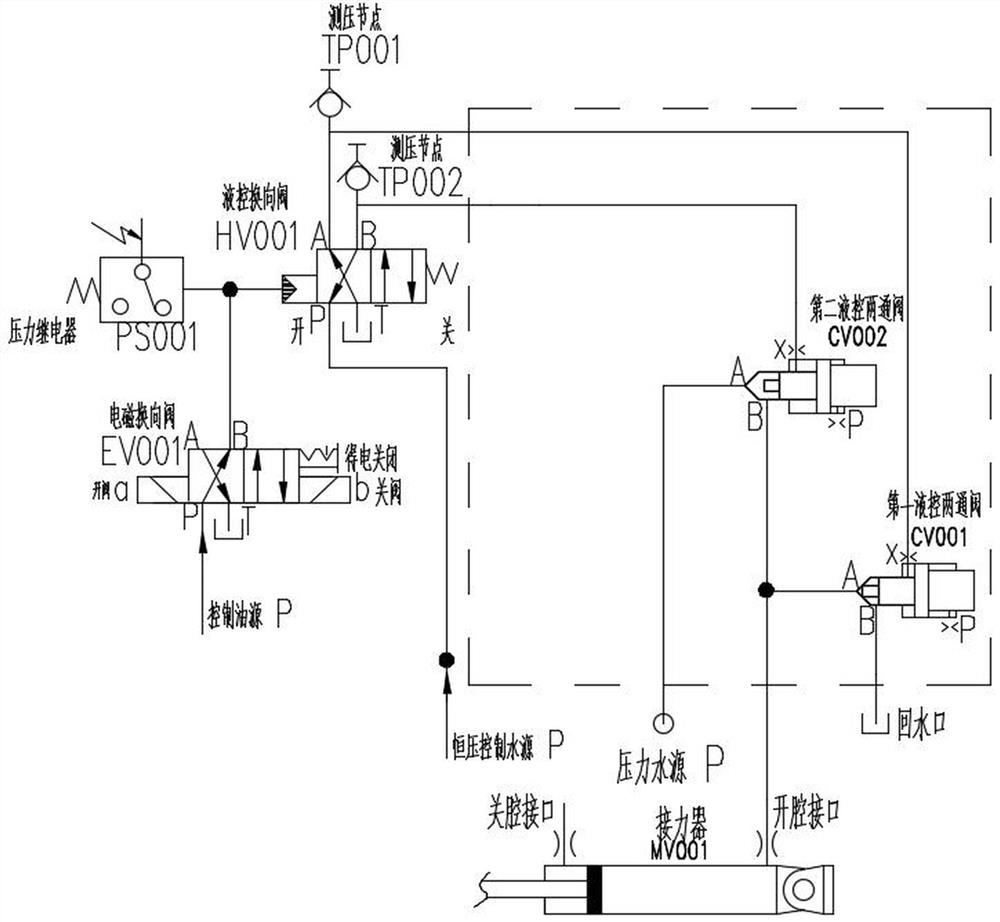

Embodiment 1

[0024] This embodiment discloses a combined control device based on green media, including an electromagnetic reversing valve, a hydraulic control reversing valve, a pilot control valve group, a servomotor, a pressure relay and two pressure measuring contacts. The directional valve includes an oil inlet control port, a water inlet, a drain port, a first control water outlet and a second control water outlet; the electromagnetic directional valve can be a double coil valve or a single coil valve, which includes Oil inlet, oil outlet and oil outlet control port; the pilot control valve group adopts a hydraulically controlled two-way valve controlled by a double chamber* (control chamber and working chamber), which includes a first hydraulically controlled two-way valve and a second hydraulically controlled two-way valve. The hydraulically controlled two-way valve, the first hydraulically controlled two-way valve and the second hydraulically controlled two-way valve both include a...

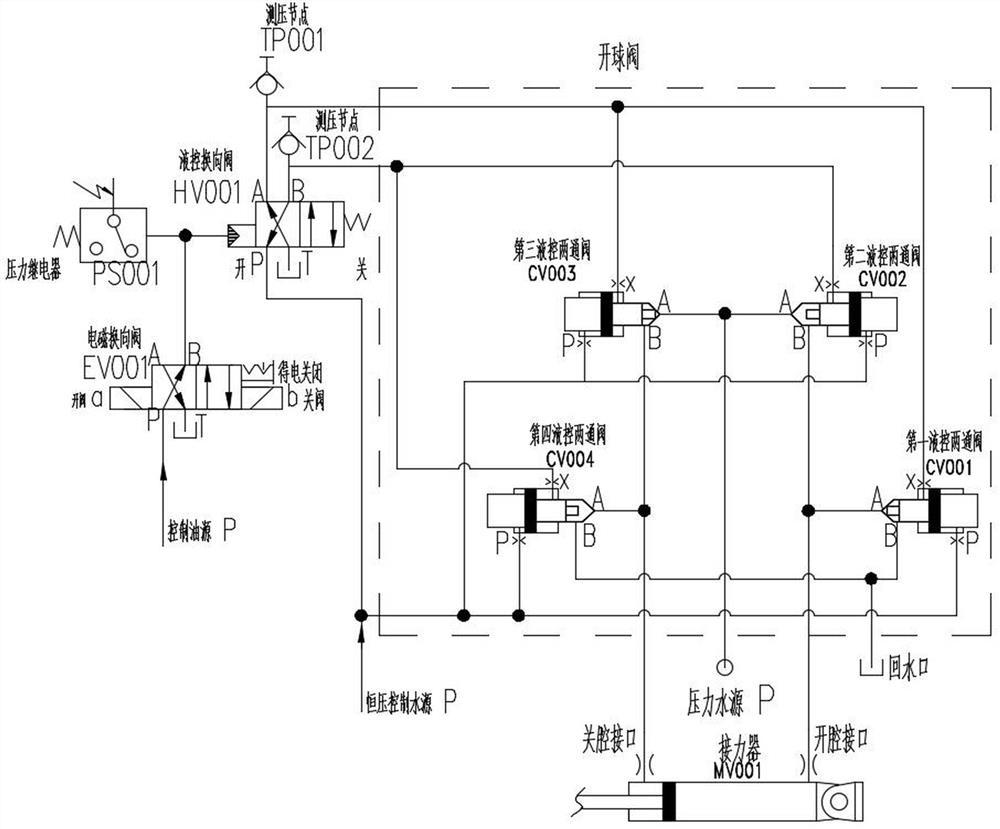

Embodiment 2

[0034]This embodiment discloses a combined control device based on green media, including an electromagnetic reversing valve, a hydraulic control reversing valve, a pilot control valve group, a servomotor, a pressure relay and two pressure measuring contacts. The directional valve includes an oil inlet control port, a water inlet, a drain port, a first control water outlet and a second control water outlet; the electromagnetic directional valve can be a double coil valve or a single coil valve, which includes Oil inlet, oil outlet and oil outlet control port; the pilot control valve group adopts a hydraulically controlled two-way valve controlled by a double chamber* (control chamber and working chamber), which includes a first hydraulically controlled two-way valve and a second hydraulically controlled two-way valve. The hydraulically controlled two-way valve, the first hydraulically controlled two-way valve and the second hydraulically controlled two-way valve both include a ...

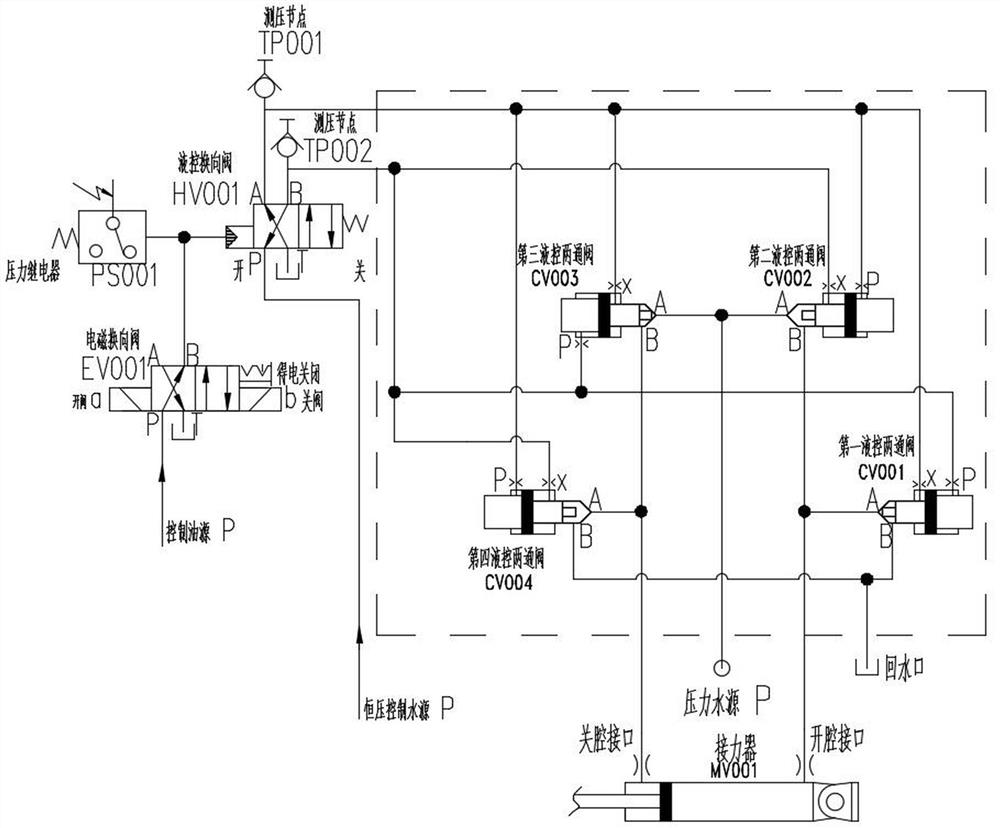

Embodiment 3

[0046] This embodiment is basically the same as Embodiment 2, the main difference is:

[0047] The constant pressure control chambers of the hydraulically controlled two-way valves in the pilot control valve group are respectively connected to the first control water outlet and the second control water outlet of the hydraulic control reversing valve. Specifically, the constant pressure control chamber of the first hydraulically controlled two-way valve and the constant pressure control chamber of the third hydraulically controlled two-way valve are connected to the second control water outlet of the hydraulically controlled reversing valve, and the second hydraulically controlled two-way valve Both the constant pressure control chamber of the fourth hydraulic control two-way valve and the constant pressure control chamber of the fourth hydraulic control two-way valve are connected with the first control water outlet of the hydraulic control reversing valve.

[0048] The pilot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com