Folding iron core for dry-type transformer

A dry-type transformer and folding technology, applied in the field of transformers, can solve the problems of complex processing technology, unequal sheet lengths, and large excitation current, and achieve the effects of small size, reduced weight, and small excitation current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

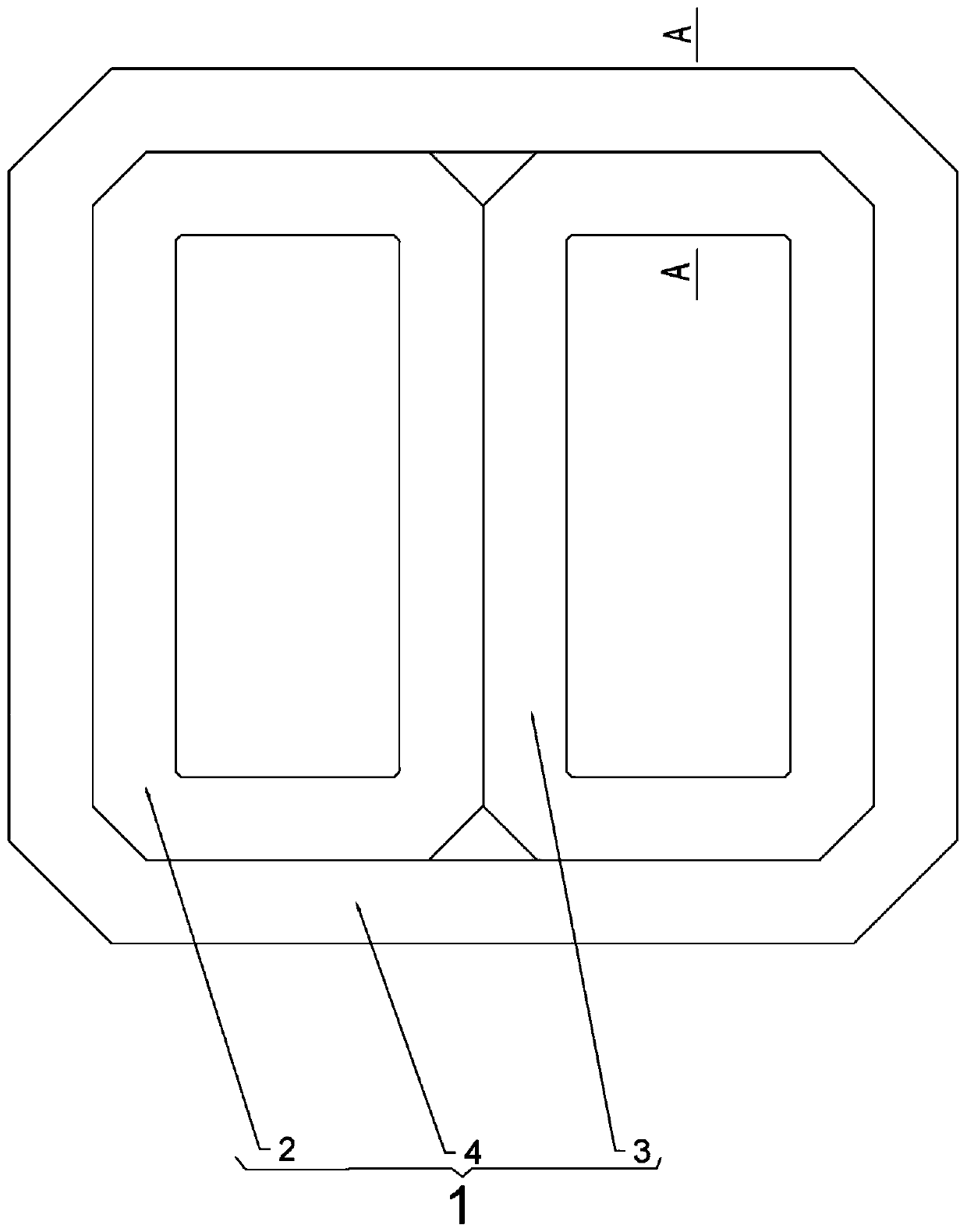

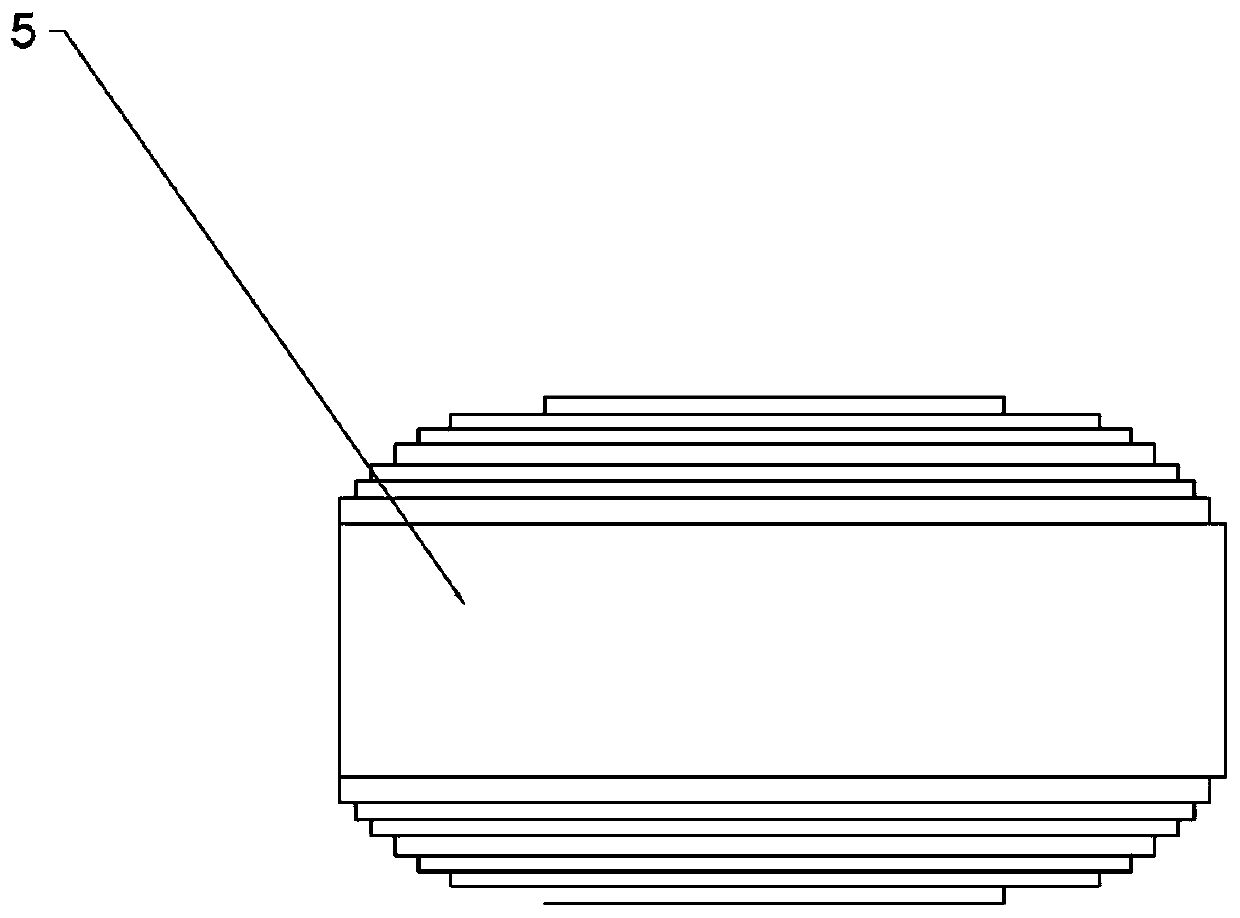

[0019] The reference signs in the drawings of the specification include: core body 1 , first core frame 2 , second core frame 3 , third core frame 4 , and silicon steel sheet 5 .

[0020] This embodiment is basically as attached figure 1 and figure 2 Shown: a folded iron core for a dry-type transformer, including a core body 1, a high-voltage coil and a low-voltage coil; the core body 1 adopts a three-phase three-column structure, and each group of iron cores includes a first core frame 2, The second core frame 3 and the third core frame 4, the first core frame 2 and the second core frame 3 have the same shape, and the first core frame 2 and the second core frame 3 are smaller than the third core frame Frame 4, the first iron core frame 2, the second iron core frame 3 and the third iron core frame 4 are all made of silicon steel sheets 5 with two widths, and the first iron core fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com