Production process of folding iron core for dry-type transformer

A technology of dry-type transformer and production process, which is applied in the field of transformers, can solve the problems of not being able to meet the demand, reduce production efficiency, and inconvenient manufacturing, etc., and achieve the effects of maintainability, improvement of production efficiency, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is further described in detail through specific implementation methods:

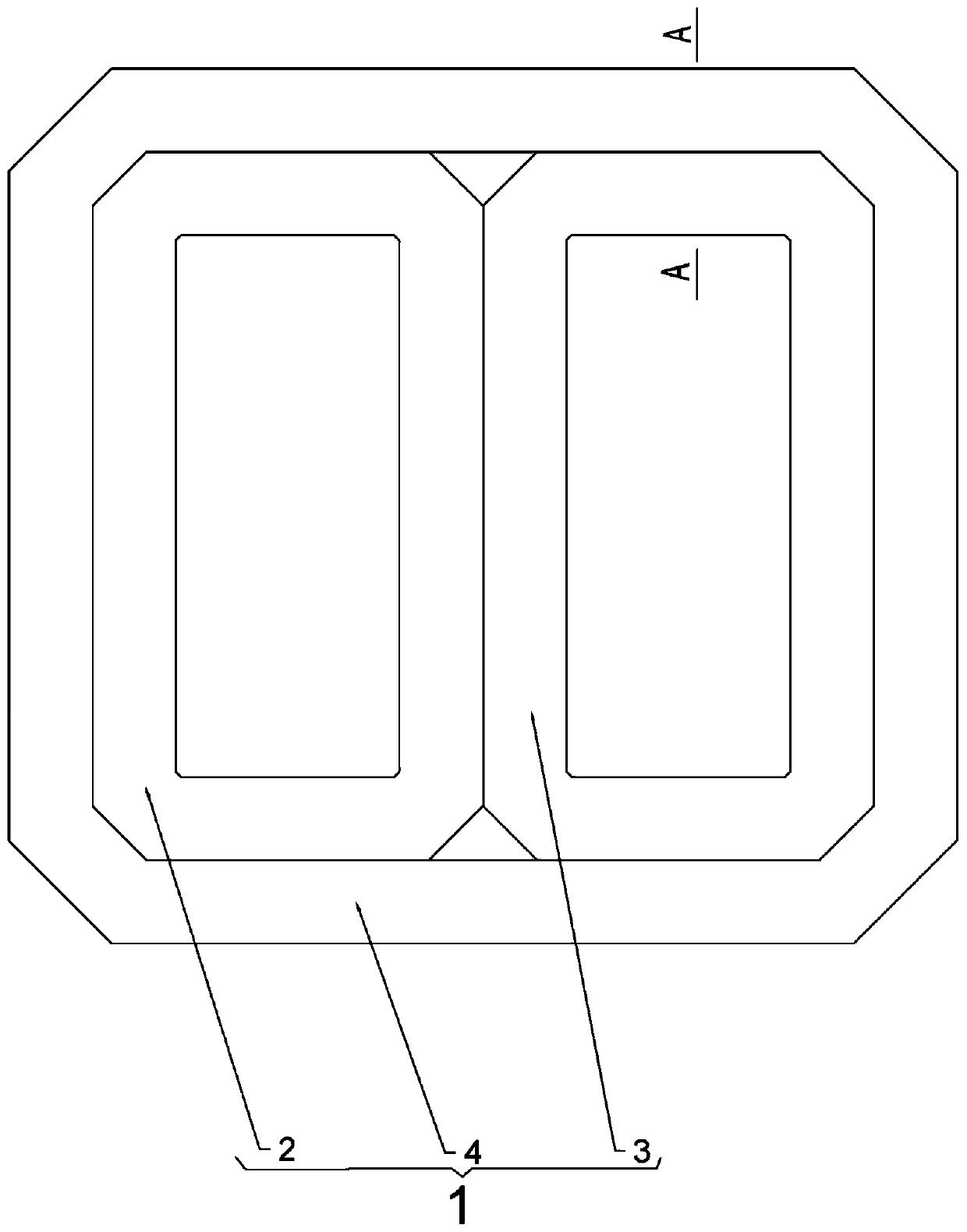

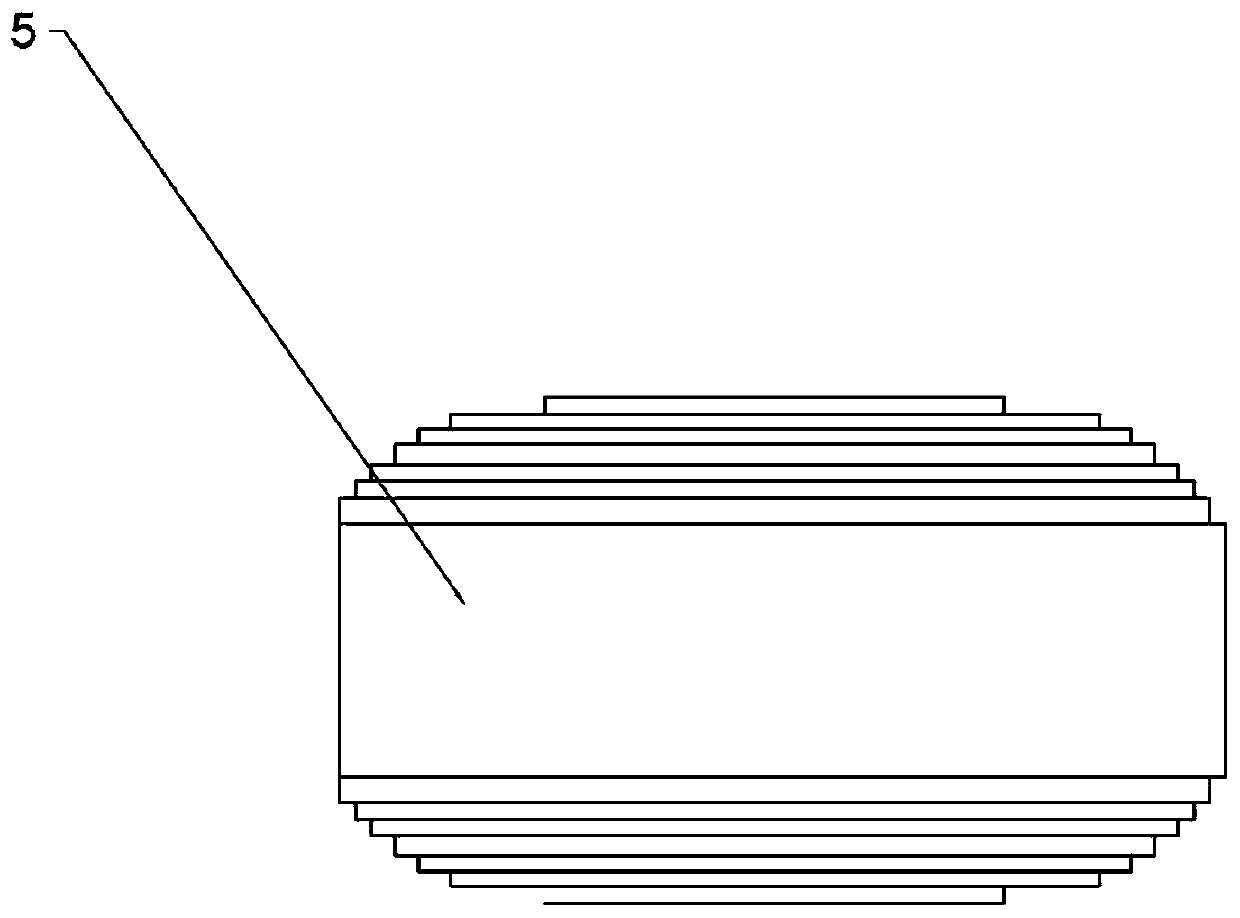

[0027] The reference numerals in the drawings of the description include: the reference numerals in the drawings of the description include: the iron core body 1 , the first iron core frame 2 , the second iron core frame 3 , the third iron core frame 4 , and the silicon steel sheet 5 .

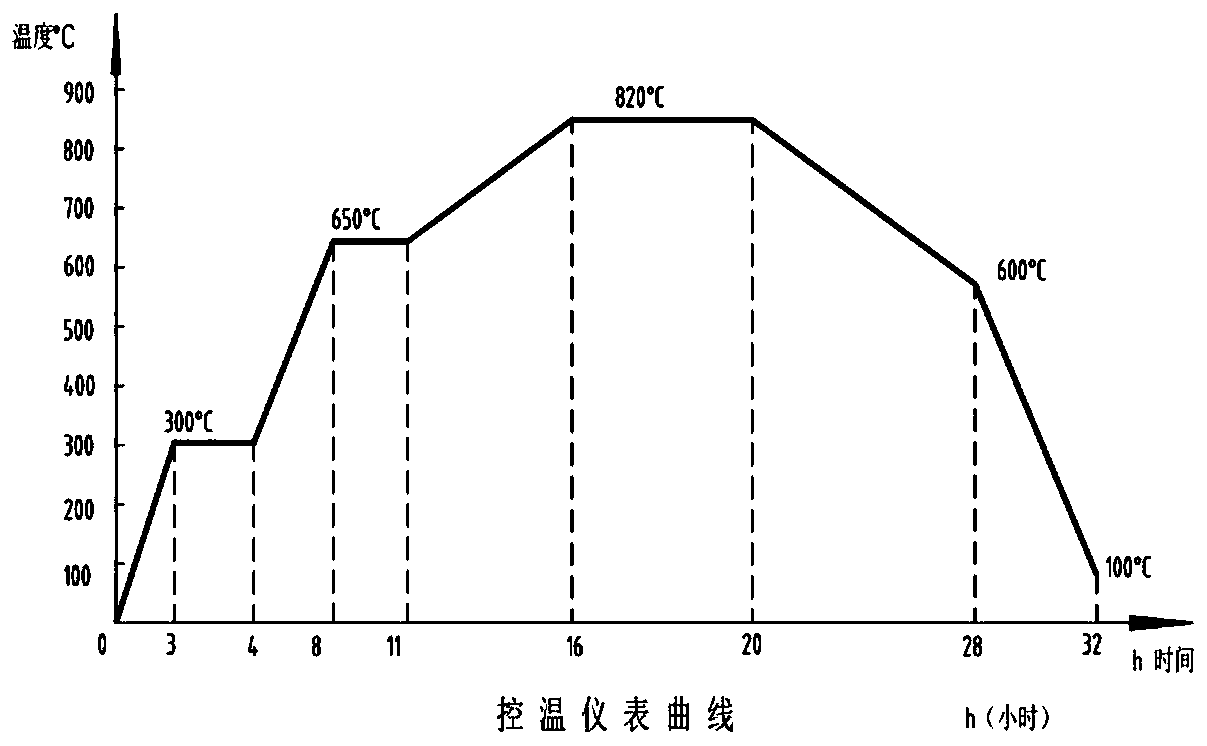

[0028] A production process for a folded iron core for a dry-type transformer includes the following steps:

[0029] (1) Cutting: cutting the silicon steel strip into a plurality of silicon steel sheets of different lengths;

[0030] (2) Processing the outer frame: folding the silicon steel sheet in the step (1) into an outer frame, wherein the outer frame is "U" shaped;

[0031] (3) processing sub-frame: the silicon steel sheet in step (1) is folded into two sub-frames, and the two sub-frames are in a "U" shape;

[0032] (4) processing the upper iron yoke: the silicon steel sheet in the step (1) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com