High-reluctance torque driving motor of hybrid electric vehicle

A technology for hybrid electric vehicles and drive motors, applied in electric vehicles, motors, electromechanical devices, etc., can solve problems that have not yet been retrieved, and achieve the effects of reducing the risk of magnetic flux cancellation and demagnetization, preventing fault propagation, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention will be described in further detail below in conjunction with the accompanying drawings.

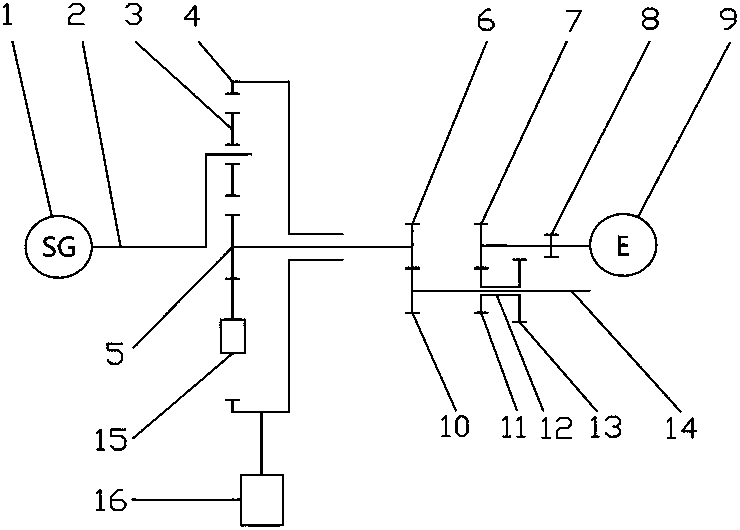

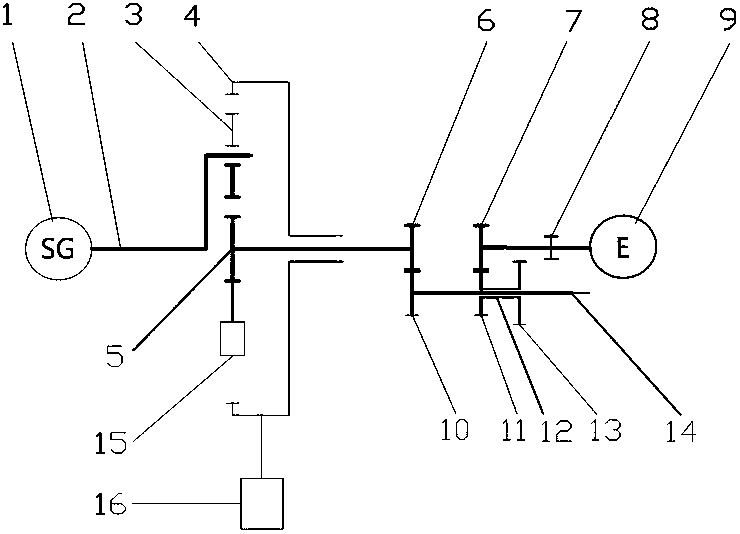

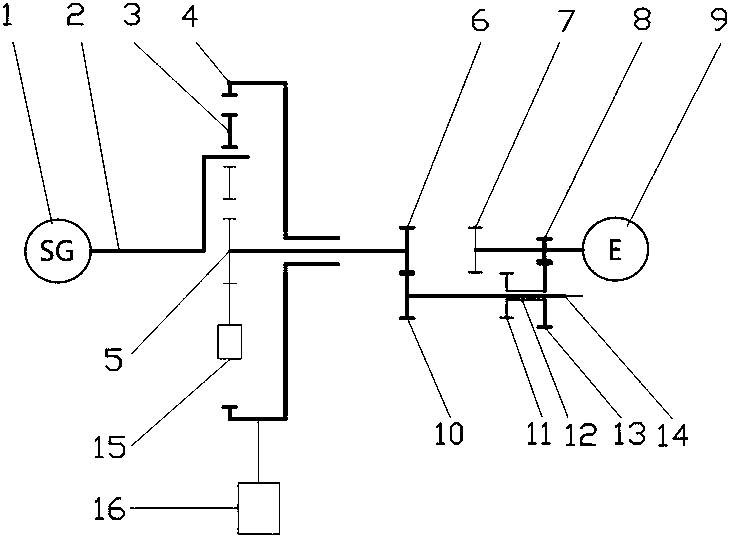

[0029] figure 1 It is a structural schematic diagram of a high reluctance torque drive motor for a hybrid electric vehicle of the present invention.

[0030] Including stator core, permanent magnet, armature winding, multi-tooth segmented rotor core, field regulating winding, non-magnetic rotor core and shaft;

[0031] 12 convex stator poles of equal width are evenly distributed inside the stator core;

[0032] The non-magnetically conductive rotor core is fixed on the shaft; the non-magnetically conductive rotor core has 8 arc-shaped grooves; the multi-tooth-shaped segmented rotor core made of laminated silicon steel sheets is placed in the arc-shaped grooves;

[0033] There is a stator slot between the two stator poles; the outer arc length of the multi-tooth segmented rotor core is not greater than the sum of the arc length of one stator pole and the arc length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com