Heat dissipation device with supercharger

A heat dissipation device and supercharger technology, which can be applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., and can solve problems that affect operating efficiency and product service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

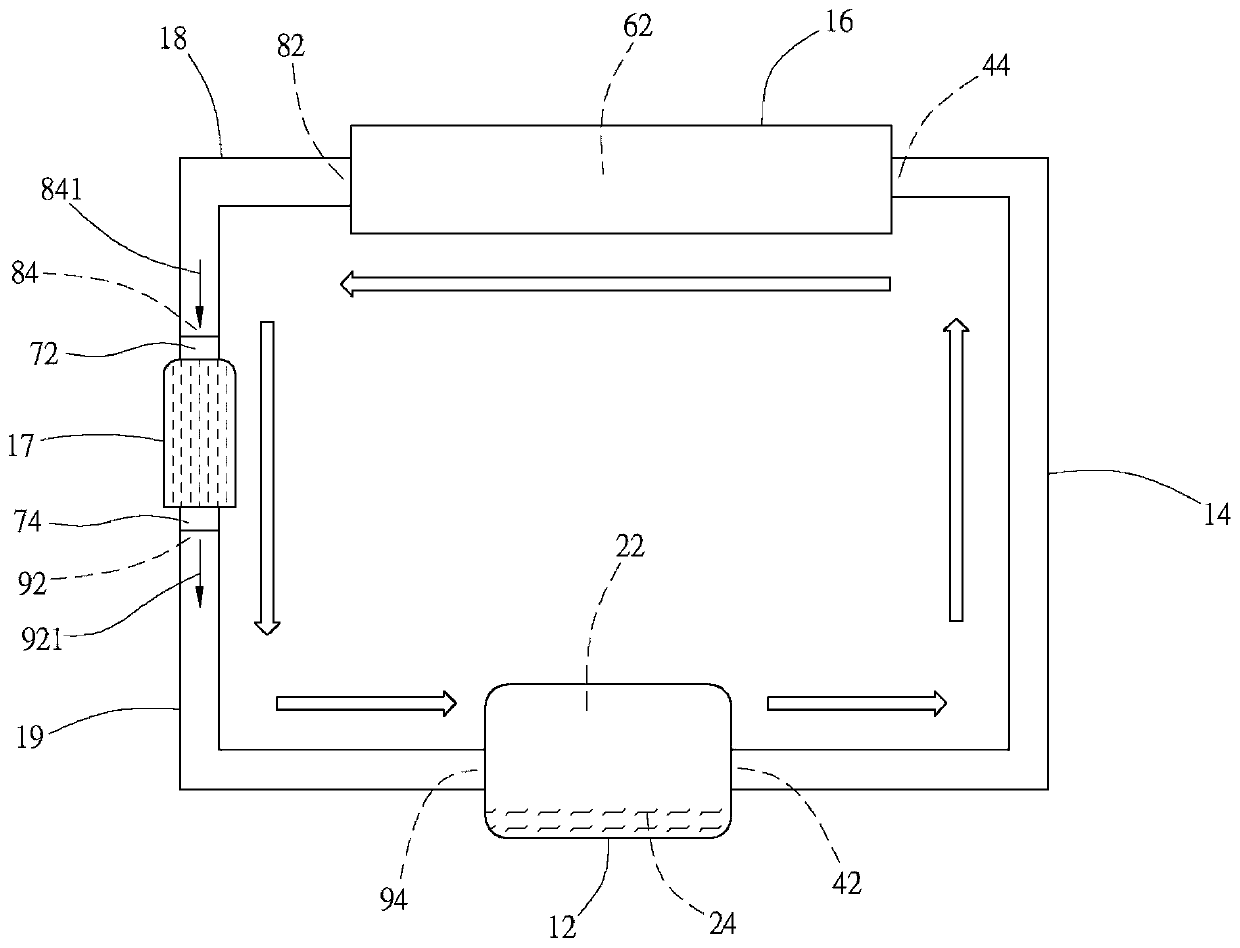

[0025] See figure 1 , The present invention provides a technical solution: a cooling device with a supercharger.

[0026] Next, the specific structure of a cooling device with a supercharger and the connection relationship of each component will be described:

[0027] The cooling device with supercharger of the present invention at least comprises a heat absorber 12, a first pipeline 14, a radiator 16, a second pipeline 18, a supercharger 17 and a third pipe Road 19, wherein the heat absorber 12, the first pipeline 14, the radiator 16, the second pipeline 18, the supercharger 17 and the third pipeline 19 are connected to form a closed circuit.

[0028] The heat absorber 12 is provided with a first internal space 22 for accommodating a liquid 24, and the heat absorber 12 is used to receive heat from a heat source (not shown in the figure) in a conductive manner, so that the liquid 24 exchanges heat with the heat And output high-temperature liquid-phase fluid, gas-phase fluid ...

Embodiment 2

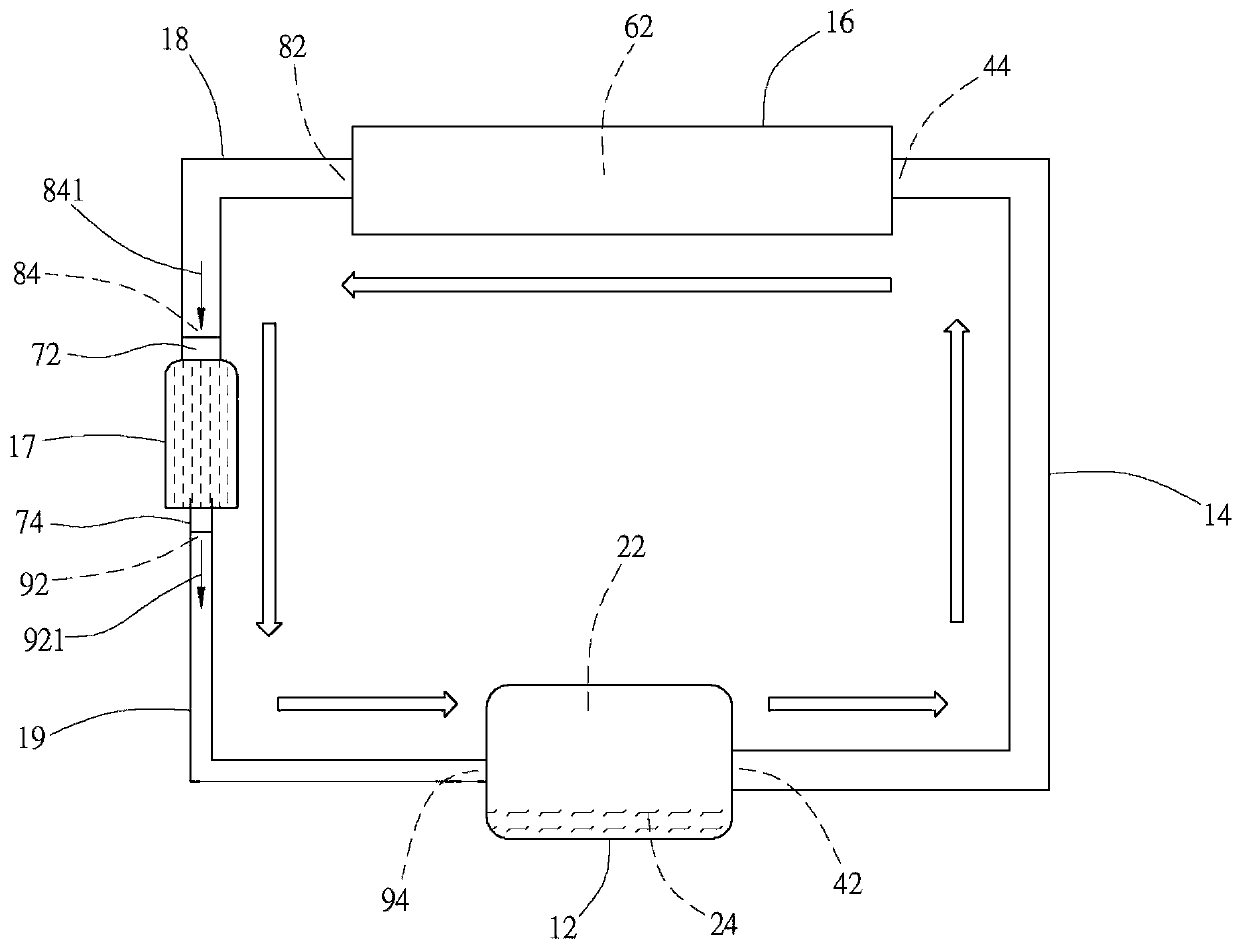

[0036] See figure 2 , the present invention provides a technical solution: a heat dissipation device with a supercharger, which at least includes a heat absorber 12, a first pipeline 14, a radiator 16, a second pipeline 18, a supercharger 17 and a third pipeline 19, wherein the heat absorber 12, the first pipeline 14, the radiator 16, the second pipeline 18, the supercharger 17 and the third pipeline 19 are connected form a closed loop.

[0037] The heat absorber 12 is provided with a first inner space 22 for containing the liquid 24. The heat absorber 12 is used to receive heat from a heat source (not shown in the figure) in a conductive manner, so that the liquid 24 exchanges heat with the heat. When outputting high temperature liquid phase fluid, gas phase fluid or fluid mixed with liquid phase and gas phase, the boiling point of the liquid 24 can be less than 100 degrees Celsius or less than 50 degrees Celsius, and the heat source can be a central processing unit (CPU), ...

Embodiment 3

[0046] The present invention provides a technical solution: a heat dissipation device with a supercharger, which at least includes a heat absorber 12, a first pipeline 14, a radiator 16, a second pipeline 18, and a supercharger 17 and a third pipeline 19, wherein the heat absorber 12, the first pipeline 14, the radiator 16, the second pipeline 18, the supercharger 17 and the third pipeline 19 are connected to form a closed loop.

[0047] The heat absorber 12 is provided with a first inner space 22 for containing the liquid 24. The heat absorber 12 is used to receive heat from a heat source (not shown in the figure) in a conductive manner, so that the liquid 24 exchanges heat with the heat. When outputting high temperature liquid phase fluid, gas phase fluid or fluid mixed with liquid phase and gas phase, the boiling point of the liquid 24 can be less than 100 degrees Celsius or less than 50 degrees Celsius, and the heat source can be a central processing unit (CPU), a chip (IC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com