Cookware assembly and cooking utensil

A technology for components and pots, applied in the field of kitchen utensils, can solve the problems of complex process, difficult to grasp the solution and materials to be cooked, affecting user experience, etc., and achieve the effect of accurate water level of rice draining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

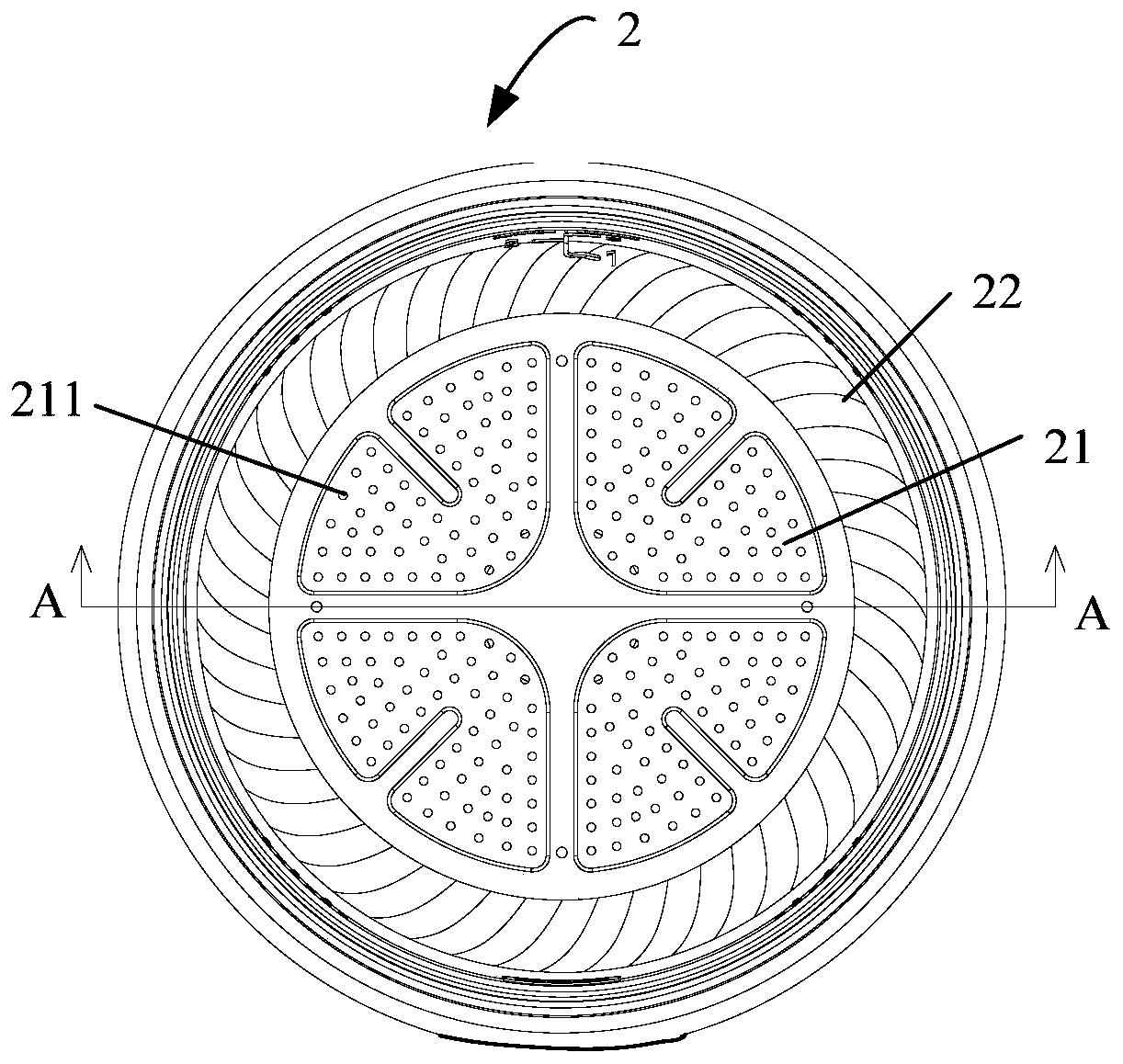

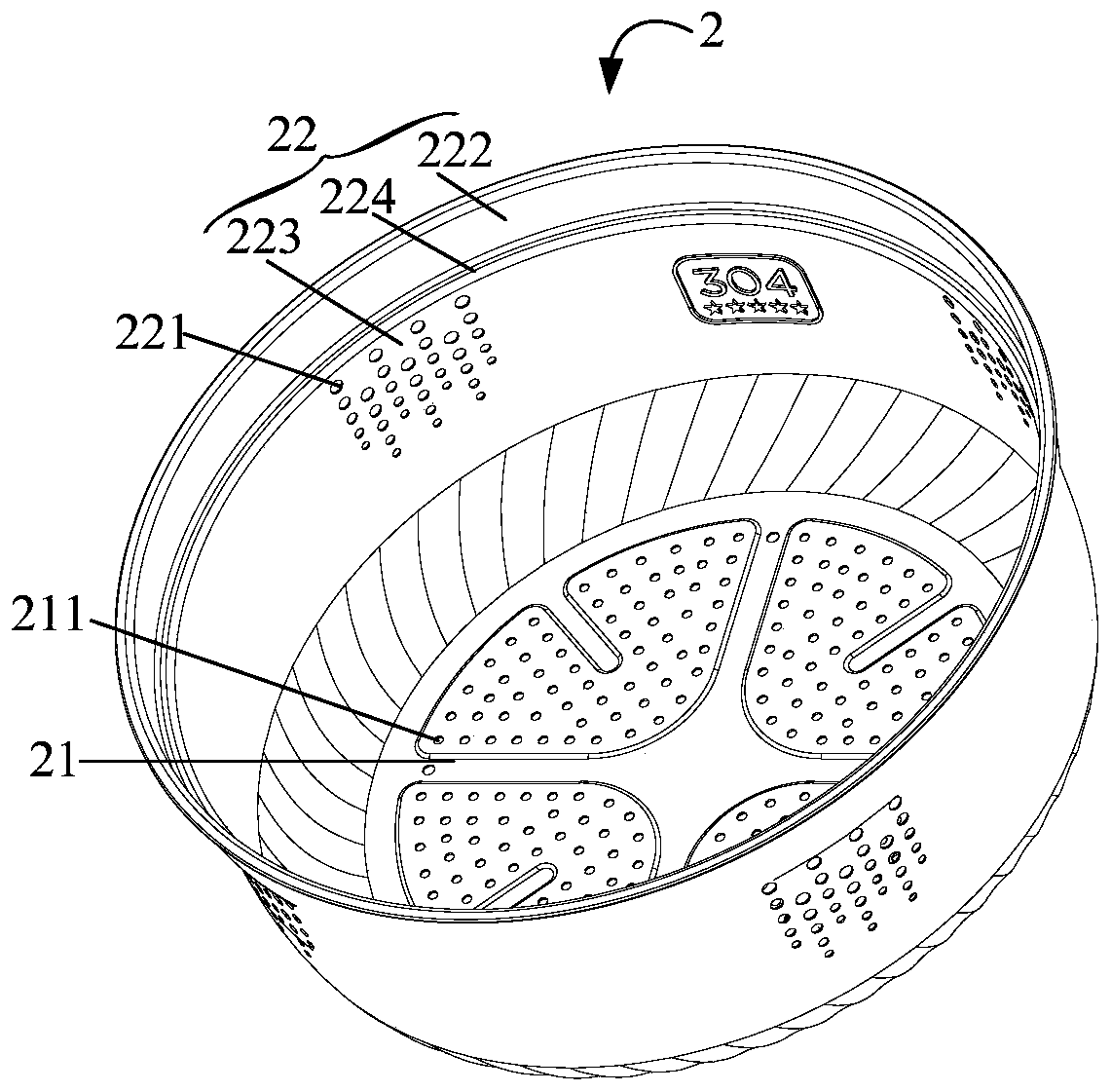

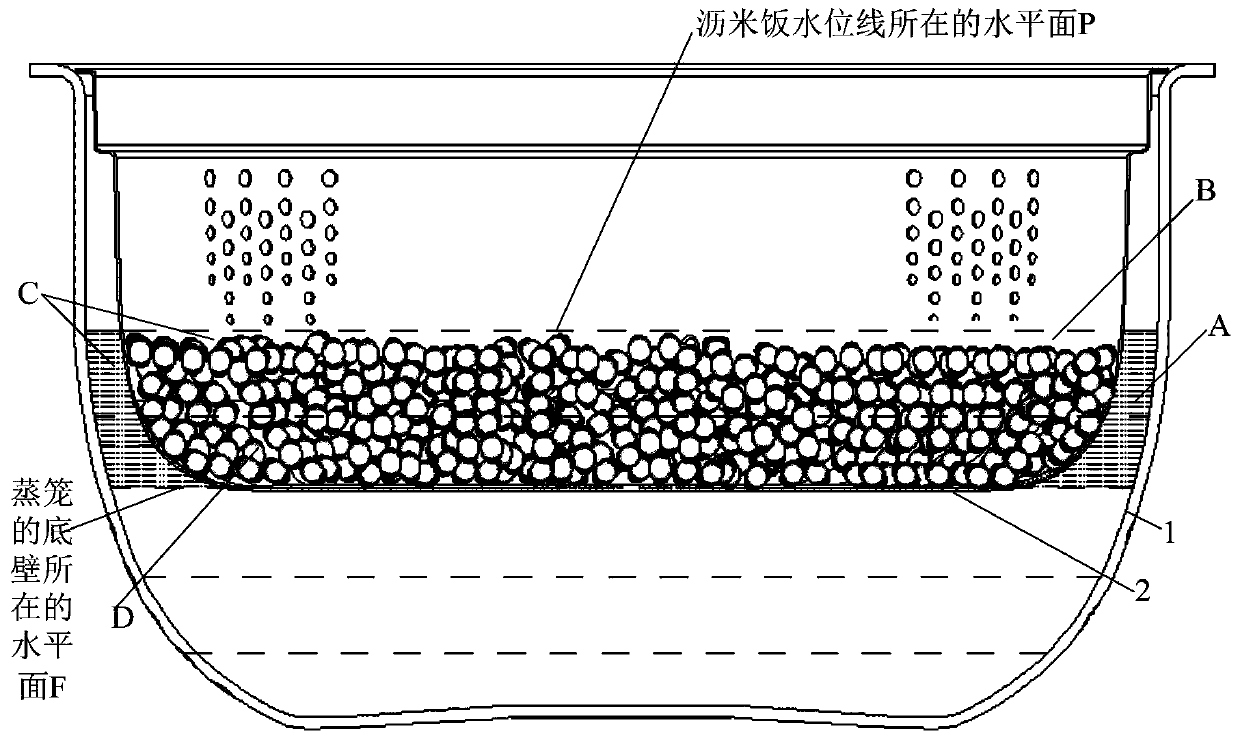

[0141] Such as figure 2 and image 3 As shown, the steamer 2 includes a side wall 22 connected to the bottom wall 21 of the steamer 2, further, the side wall 22 of the steamer 2 is connected above the bottom wall 21 of the steamer 2, and further, the side wall 22 is annular, The annular side wall 22 is connected to the edge of the bottom wall 21, and the annular side wall 22 and the bottom wall 21 define a space for containing the materials to be cooked when draining the rice.

[0142] Further, the inner pot and / or the steamer are provided with a plurality of water level lines for draining rice from top to bottom, and all the water level lines for draining rice are higher than the bottom wall of the steamer, that is, all the water level lines for draining rice are higher than the bottom wall of the steamer. The lowest point of the bottom wall.

[0143] Set multiple water level lines for draining rice from top to bottom, which can meet the needs of users for various cooking ...

Embodiment 2

[0224] The difference from Embodiment 1 is that the pot assembly includes a first measuring tool configured to quantify the volume of the material to be cooked, wherein the first measuring tool has a quantitative volume V11; the inner side wall of the inner pot and the bottom wall of the steamer are located The horizontal plane of the steamer and the horizontal plane where the drained rice water level is located enclose the first storage area 4, and the horizontal plane where the bottom wall of the steamer is refers to the horizontal plane where the lowest point of the upper surface of the steamer bottom wall is. In the first storage area 4, the steamer The volume is B1, B1≤(V11×n+100)ml, where n is the coefficient of the first measuring tool of the material to be cooked corresponding to the water level of drained rice.

[0225] According to B1≤(V1V11×n+100)ml, the material can be completely separated from the solution after draining the rice, so that the taste of the food on t...

Embodiment 3

[0231] The difference with Embodiments 1 and 2 is that, as Figure 16 to Figure 18 Shown, steamer 2 does not have side wall 22.

[0232] The pot assembly includes: a second measuring tool configured to quantify the volume of the material to be cooked, wherein,

[0233] The second measuring tool has a quantitative volume V12; the inner side wall of the inner pot, the horizontal plane where the bottom wall of the steamer is located, and the first storage area 4 with the water level line of drained rice as the upper boundary, and the horizontal plane where the bottom wall of the steamer is located refers to the bottom wall of the steamer The horizontal plane where the lowest point of the upper surface is located, the volume of the first accommodation area 4 is B2, then B2≤(V12×n+100)ml, wherein, n is the second measuring tool of the material to be cooked corresponding to the water level line of drained rice coefficient.

[0234] According to B2≤(V12×n+100)ml, the material can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com