Aluminum alloy section bar cutting device

An aluminum alloy profile and cutting device technology, which is applied in positioning devices, large fixed members, metal processing equipment, etc., can solve the problems of difficulty in cutting aluminum materials of different specifications, reduce the applicability of cutting equipment, and increase the cost of use, and achieve practicality. Strong, improve the scope of application, use stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

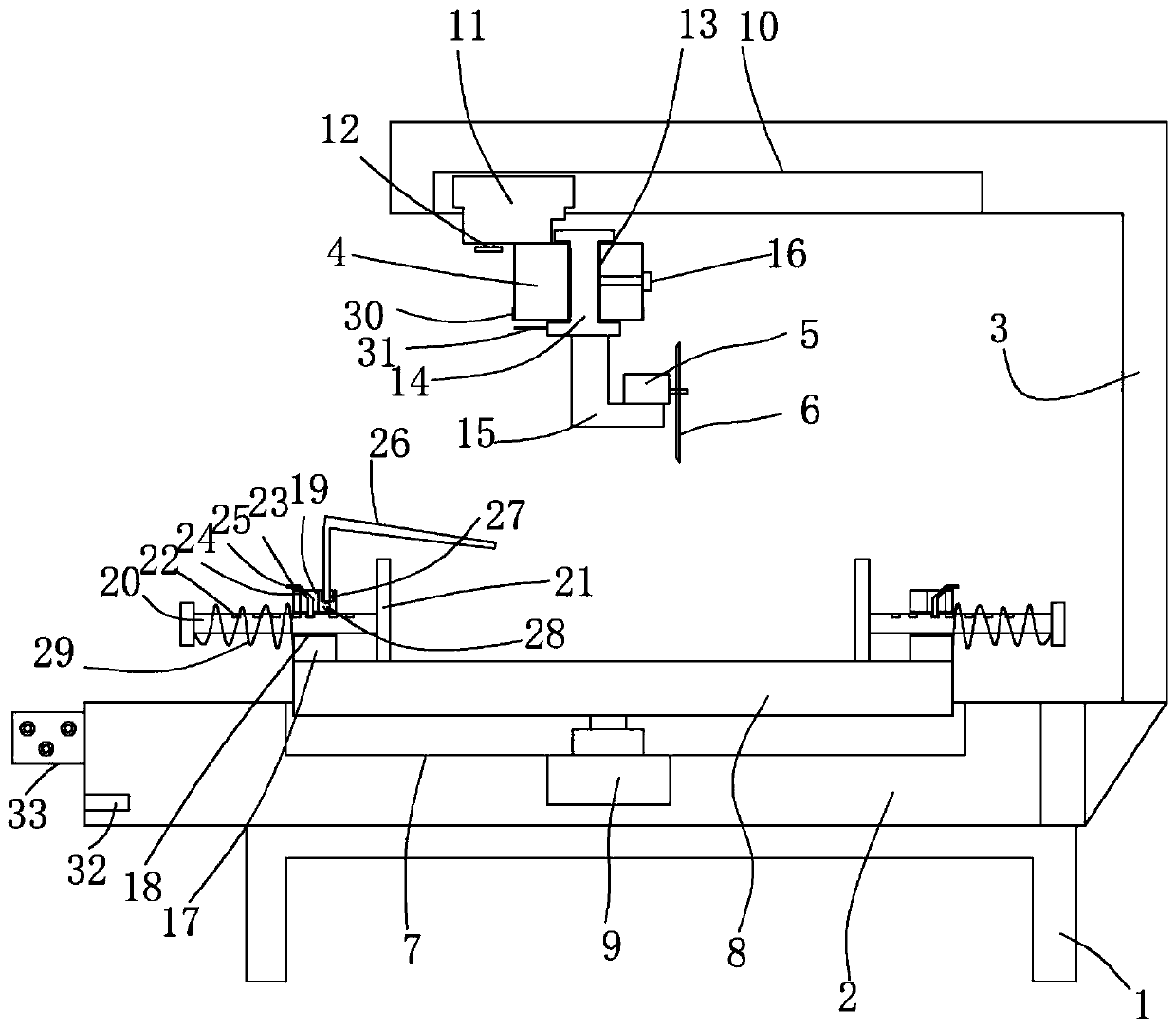

[0017] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0018] See figure 1 , an aluminum alloy profile cutting device, comprising a bracket 1, a cutting platform 2 fixed on the bracket, a support plate 3 fixed on the bracket, a cutting seat 4 is arranged on the support plate, and the The cutting seat is provided with a driving motor 5 and a cutting tool 6 is fixed on the main shaft of the driving motor, and a lifting cavity 7 is provided on the cutting platform, and a carrying platform 8 is arranged in the lifting cavity. A lifting hydraulic cylinder 9 is fixed between the bearing platform and the bottom wall of the lifting cavity, a T-shaped adjustment chute 10 is arranged on the support plate, and a T-shaped adjustment chute 10 is integrally formed on the top surface of the cutting seat. Slider 11 is provided with a positioning screw 12 on the T-shaped slider, and the T-shaped slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com