Ejecting and tray centering method

A lifting and pallet technology, applied in the direction of conveyor objects, transportation and packaging, roller table, etc., can solve problems such as unsatisfactory guiding and centering effect, failure to achieve centering effect, and increase of manual re-inspection, so as to achieve a smooth implementation process. , The effect of short operation time, strong versatility and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, during the transfer process of the pallet carrying goods on the conveyor line, a corresponding centering process needs to be configured.

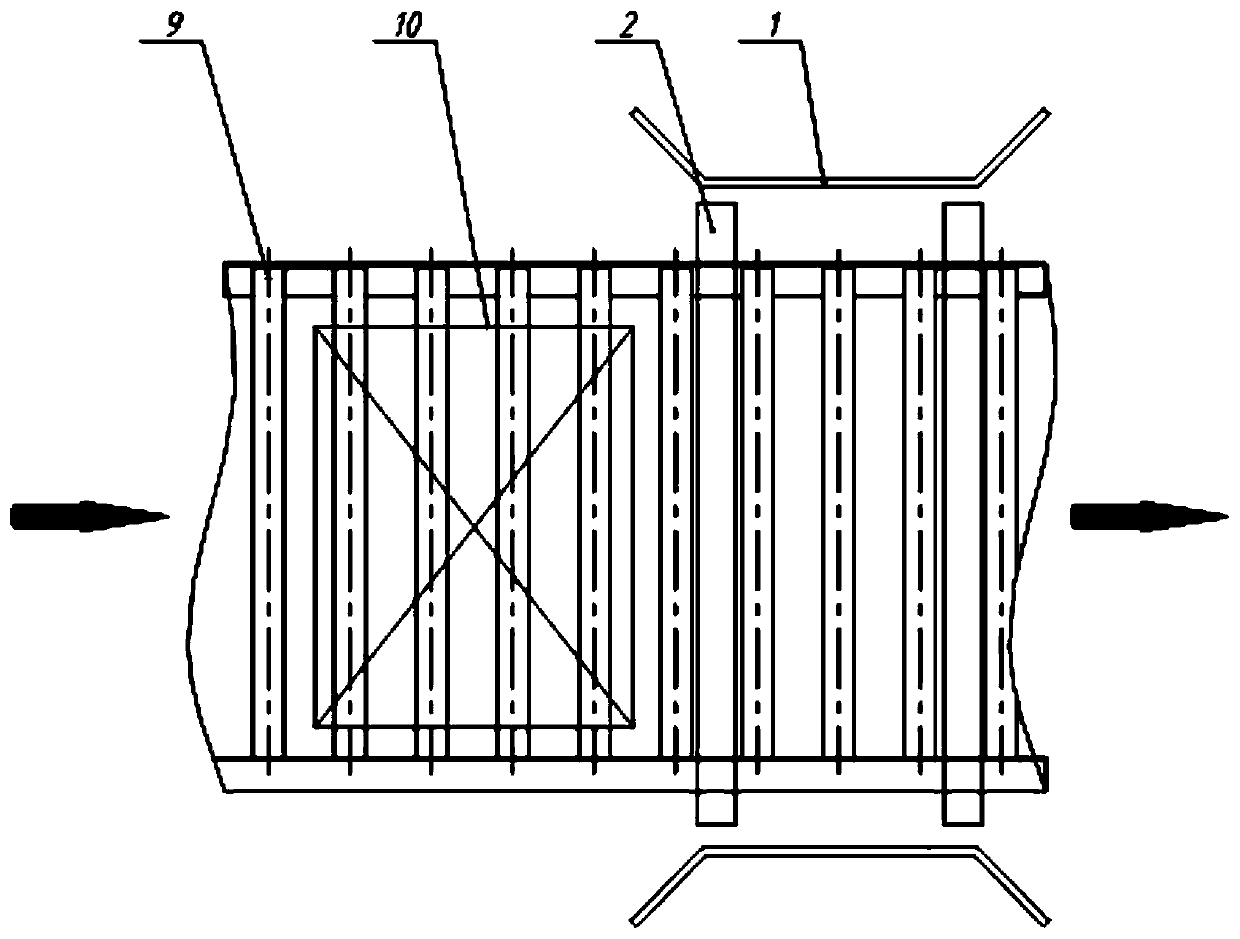

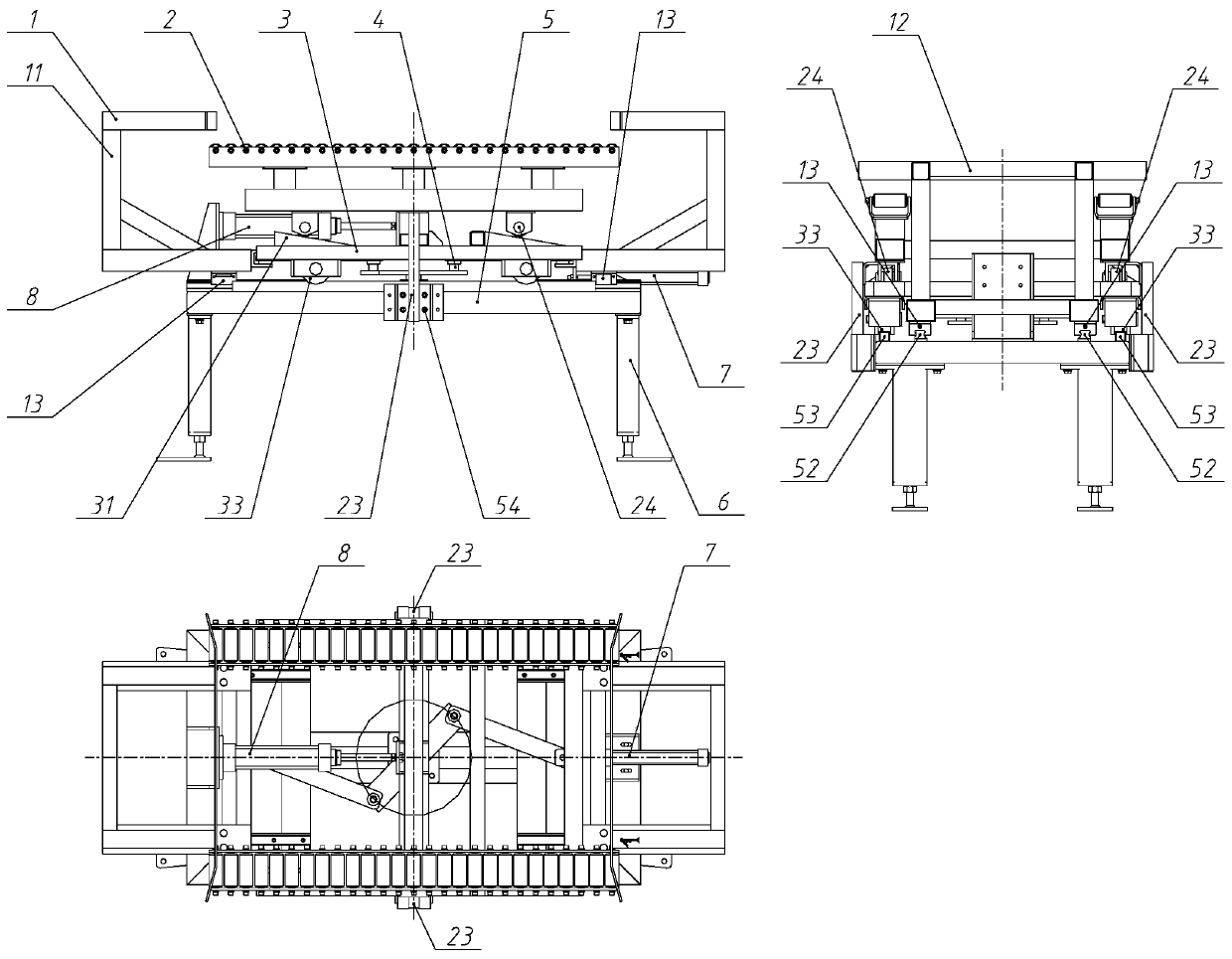

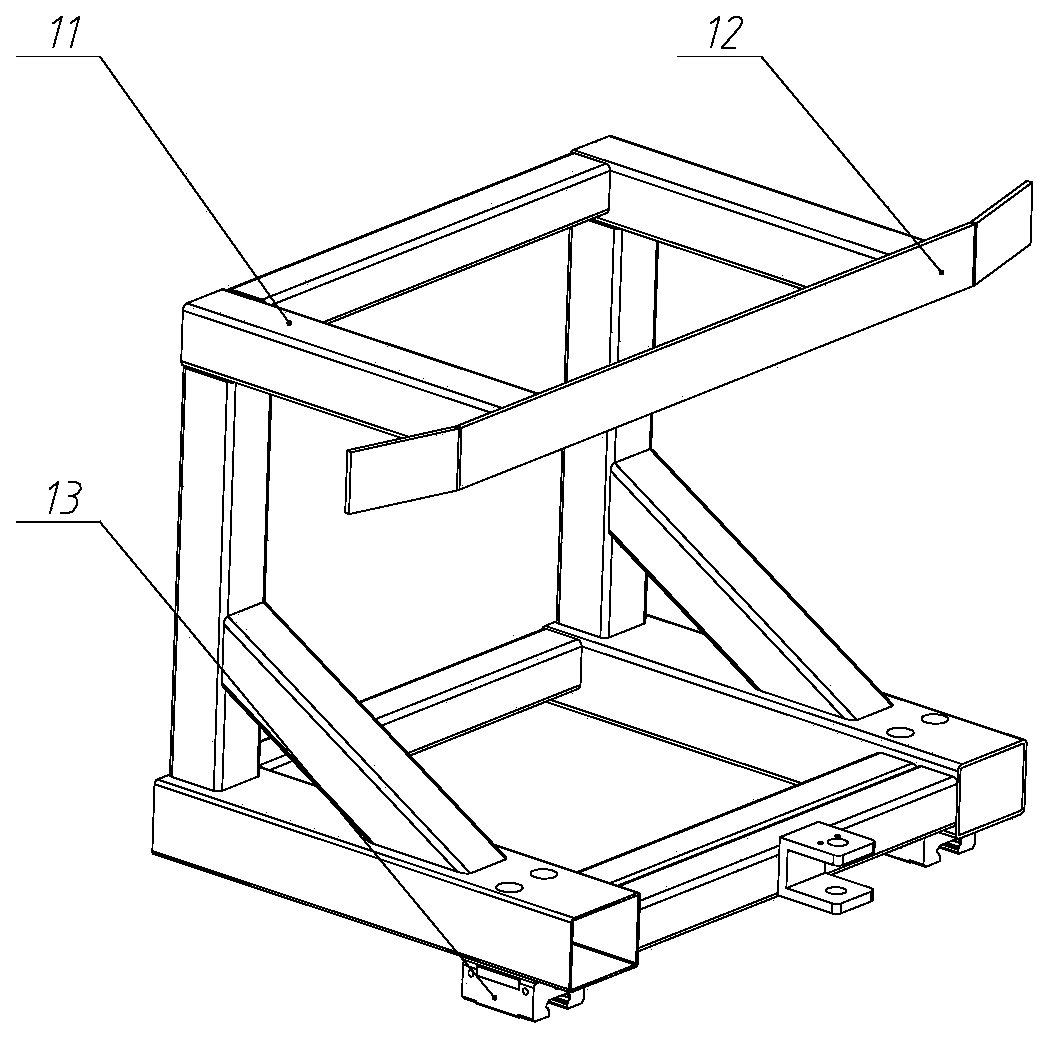

[0035] like figure 1 As shown, the roller conveying line 9 of the lifting pallet centering method and the centering device described in the present application is applied, the pallet 10 carrying goods is transported on the roller conveying line 9, and the jacking described in the present application is arranged below the roller conveying line 9. Lifting tray centering device.

[0036] When the jacking roller assembly 2 is raised in the roller gap along the roller conveying line 9, the cargo hand can be lifted up and separated from the roller conveying line 9, and then the centering frame 1 is used to squeeze from both sides to the center to achieve Adjustment of cargo.

[0037] After the goods are centered and positioned, the jacking roller assembly 2 descends vertically, and the goods are replaced on the roller conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com