Wheel clamp module for inspection and operation

A technology of rollers and worm gears, applied in the field of wheel clamp modules for inspection and operation, to achieve good versatility and applicability, easy disassembly or replacement, and improved maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

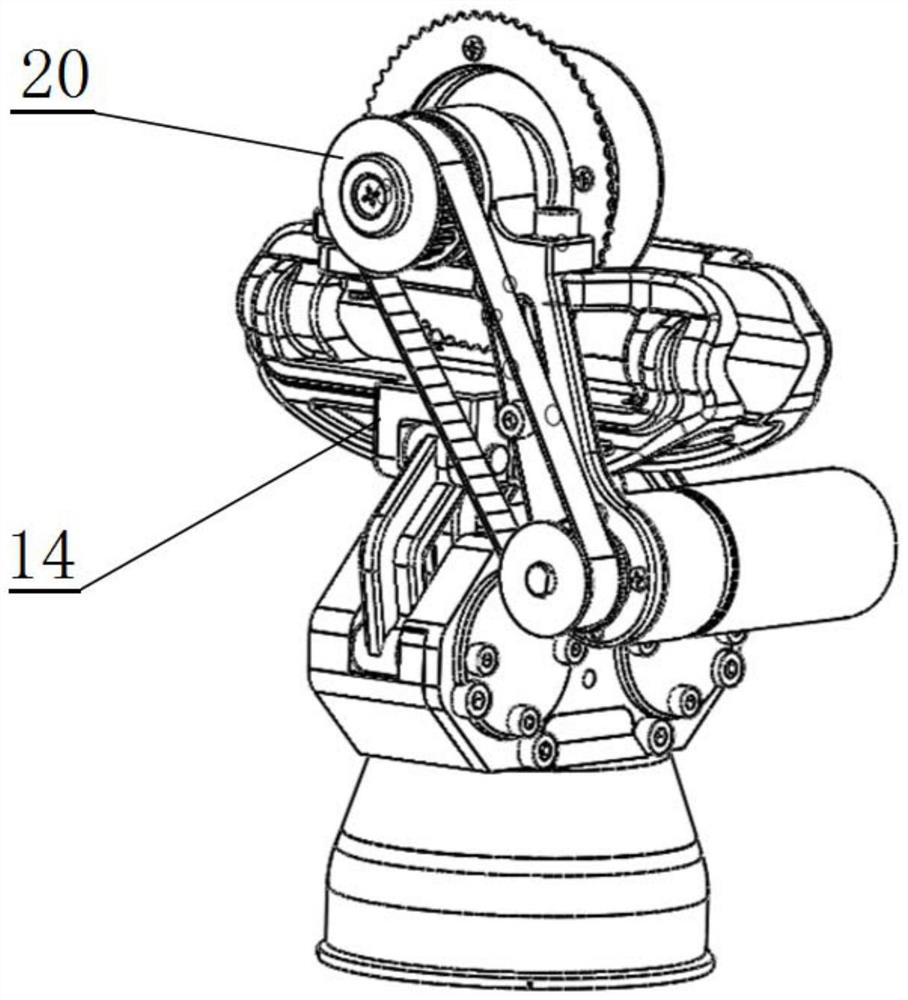

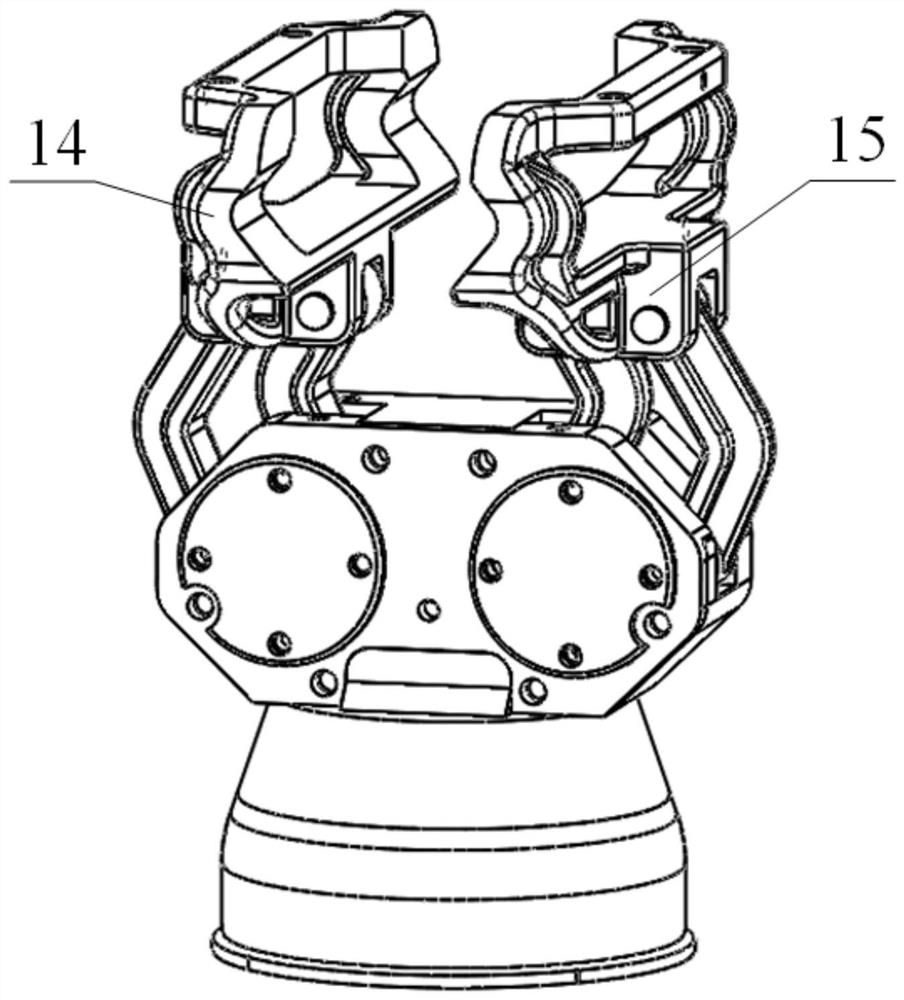

[0031] Such as Figure 1 to Figure 5 Shown is an embodiment of a wheel clamp module of the present invention. A wheel clamp module such as figure 1 As shown, it includes a clamping transmission assembly, a clamping assembly and a roller assembly, the output end of the clamping transmission assembly is connected to the clamping assembly, the roller assembly is fixed on the clamping assembly, and the roller assembly includes a roller 13 and a driving roller 13 to rotate The motor 16, the motor 16 drives the roller 13 to rotate through the synchronous belt transmission member. The clamping transmission component controls the clamping component to complete the opening and closing action. The clamping component can clamp the cable, hang the roller assembly on the top of it on the cable, and the motor 16 drives the roller 13 to rotate, so that the wheel clamping module can be on the cable. Run mobile.

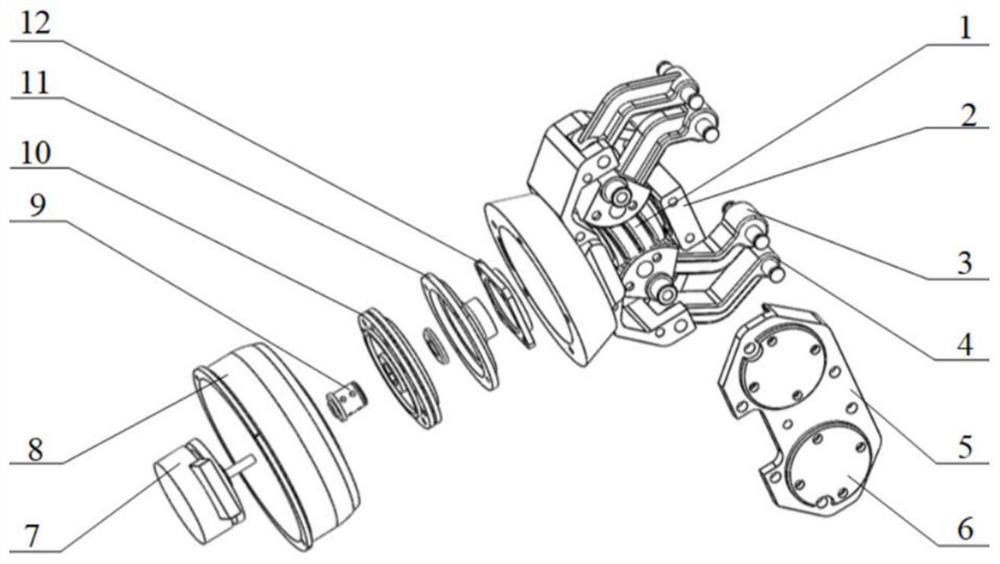

[0032] Among them, such as figure 2As shown, the clamping transmission asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com