Low-temperature co-fired ceramic raw material belt and preparation method thereof

A technology of low-temperature co-fired ceramics and raw material tape, which is applied in the field of low-temperature co-fired ceramics, can solve problems such as large sintering shrinkage, and achieve good matching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

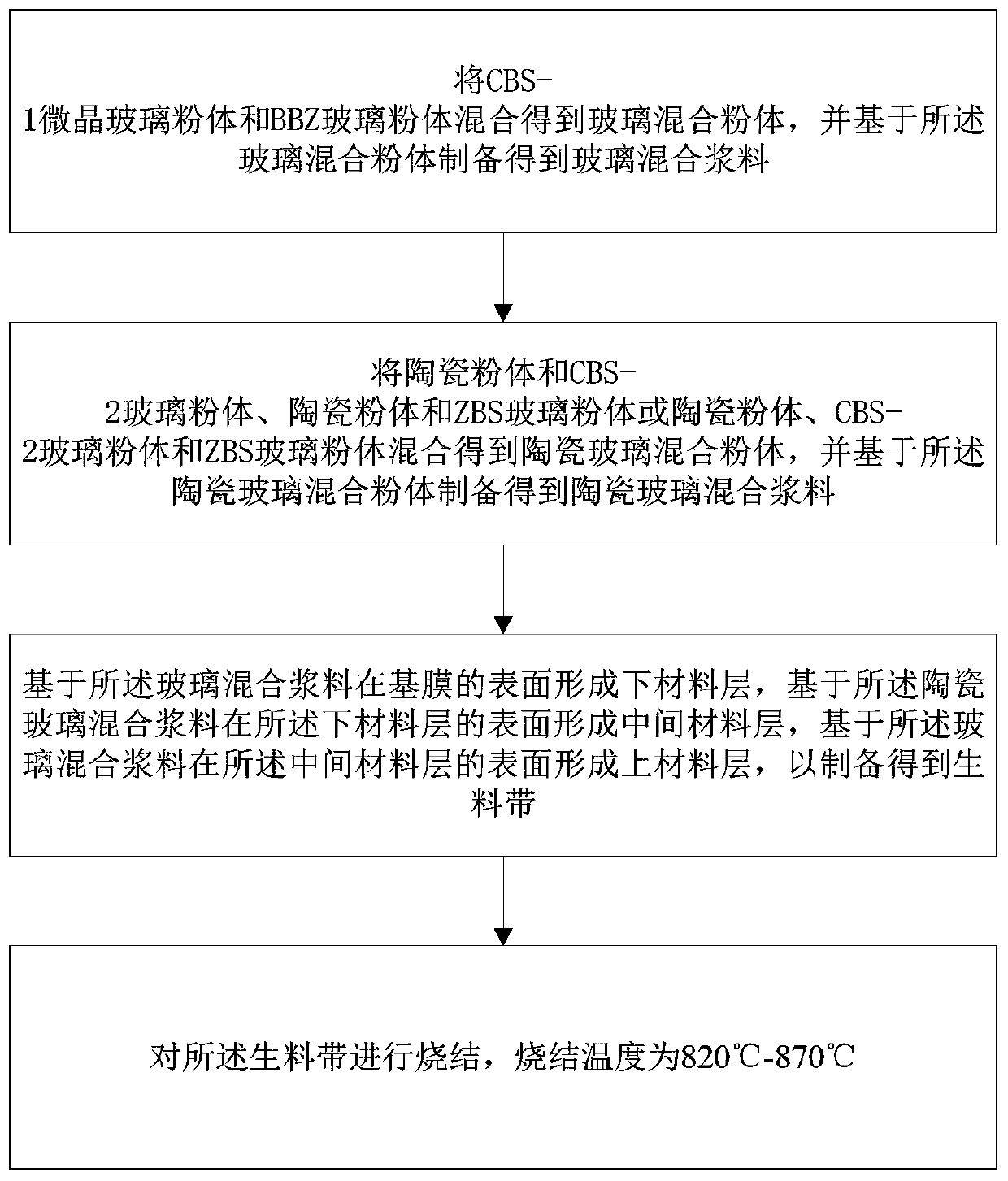

[0046] Such as figure 1 As shown, this embodiment provides a method for preparing a low-temperature co-fired ceramic green belt, the preparation method comprising:

[0047] Step 1) Mixing CBS-1 glass-ceramic powder and BBZ glass powder to obtain a glass mixture powder, and preparing a glass mixture slurry based on the glass mixture powder.

[0048] As an example, the preparation method of the CBS-1 glass-ceramics powder includes:

[0049] The CBS-1 glass-ceramic powder includes the following components by mass ratio: 35%-37% of CaO, 33%-35% of B 2 o 3 , 27%-30% SiO 2 And 2%-4% TiO 2 ;

[0050] Weigh according to the above ratio, mix and put into a crucible, and melt it into glass liquid at 1450°C-1500°C, quench it into a glass block, and grind it into the CBS-1 glass-ceramic powder by a sand mill;

[0051] Wherein, the particle size D50 of the CBS-1 glass-ceramic powder is 2.0 μm-2.2 μm.

[0052] Specifically, before the mixed raw materials are loaded into the crucible,...

Embodiment 2

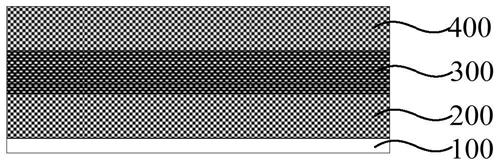

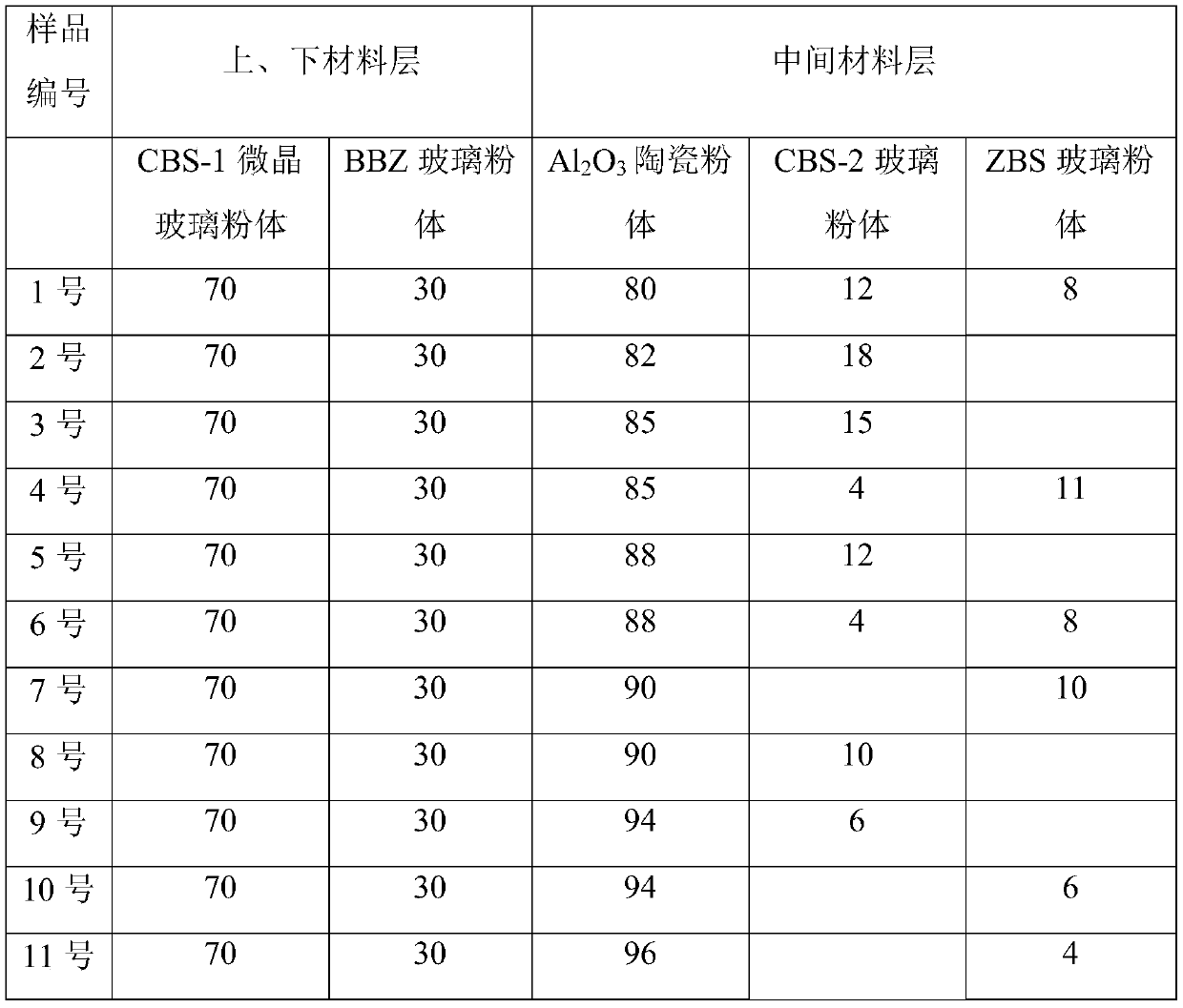

[0119] Such as figure 2 As shown, the present embodiment provides a low-temperature co-fired ceramic raw tape, which is formed on the surface of the base film 100, and the raw tape includes from bottom to top: a lower material layer 200, an intermediate material layer 300, and an upper material layer 400; Wherein, the lower material layer 200 is made of glass mixed slurry based on CBS-1 glass-ceramic powder and BBZ glass powder, and the intermediate material layer 300 is made of ceramic powder and CBS-2 glass powder. , ceramic powder and ZBS glass powder or ceramic powder, CBS-2 glass powder and ZBS glass powder made of ceramic glass mixed slurry, the upper material layer 400 is made based on CBS-1 glass-ceramic powder Body and BBZ glass powder made of glass mixed slurry.

[0120] In this example, the base film 100 includes a PET film, of course, other materials that can be used as the base film are also applicable to this example, and the material of the base film is not li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com