Method for driving seesaw flywheel power machine to operate by utilizing gravity, magnetic force and buoyancy

A buoyancy-driven, seesaw technology, which is applied in the direction of mechanisms, engines, and engine components that generate mechanical power, can solve the problems of high energy consumption, environmental pollution, and high operating costs, and achieves high power utilization, high power conversion, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

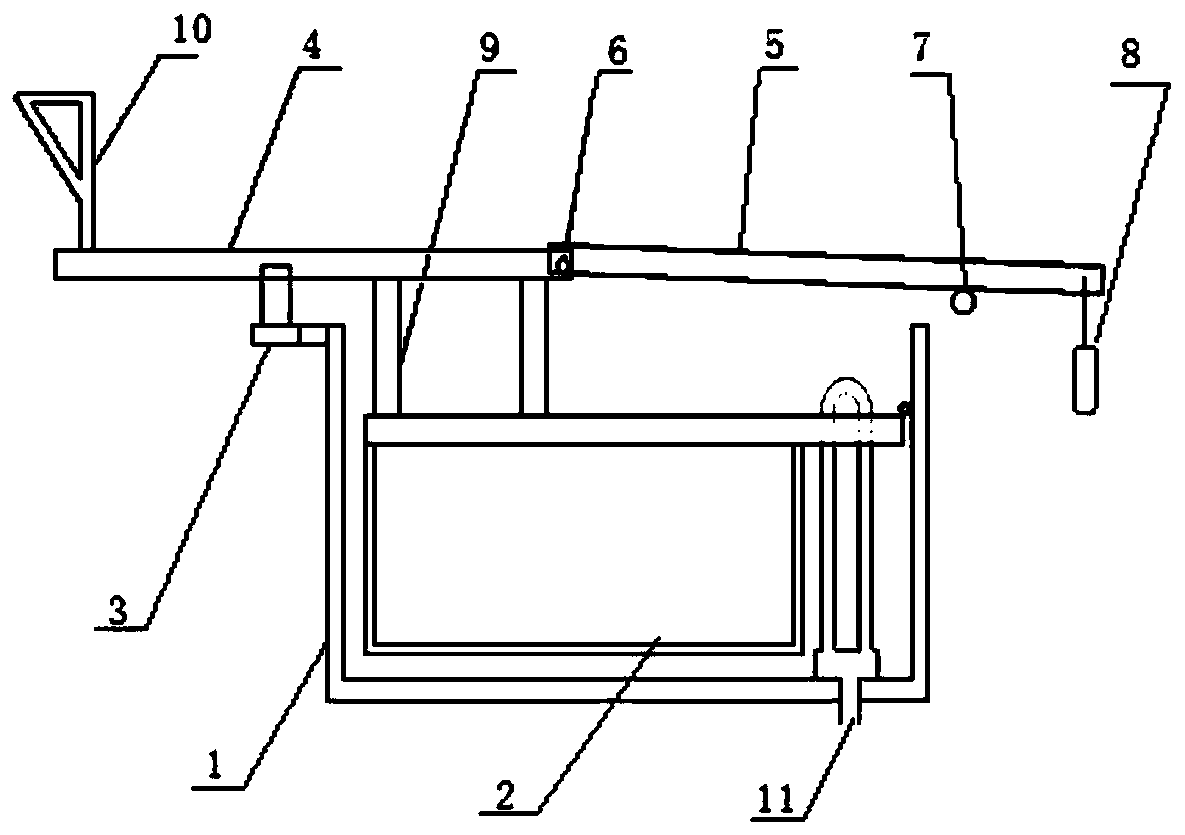

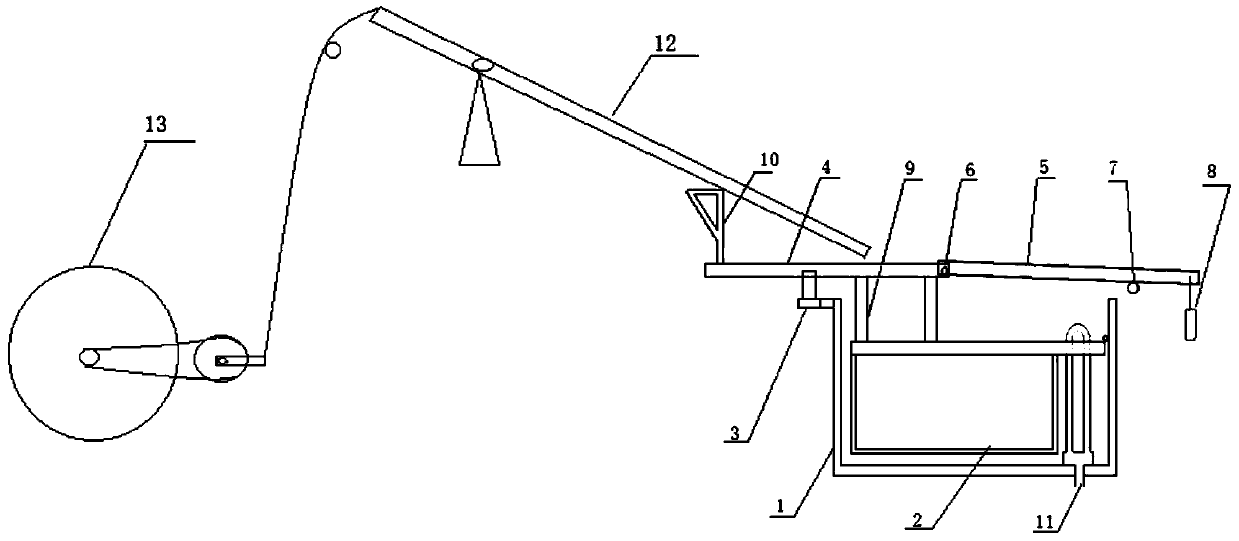

[0030] see figure 1 and figure 2 , a kind of method that utilizes gravity, magnetic force and buoyancy to drive seesaw flywheel power machine operation, and its method comprises the following steps.

[0031] (1) A water tank (1) with a built-in automatic water tank (11) is set, and the height of the siphon of the automatic water tank (11) is the same as or slightly higher than the height of the upper plane of the buoyancy tank (2).

[0032] (2) A buoyant tank (2) is set in the water tank (1), and the buoyant tank (2) can float and rotate around its support rotation point fixed on the wall of the water tank (1).

[0033] (3) A push rod (4) with a magnetic touch switch (3) is erected on the buoyant tank (2), and the push rod (4) is fixed on the buoyant tank (2) through a bracket (9) On the upper platform of the upper platform, which is horizontal to the water tank (1), one end protrudes out of the tank body, and the protruding top end is provided with a pennant-shaped support...

Embodiment 2

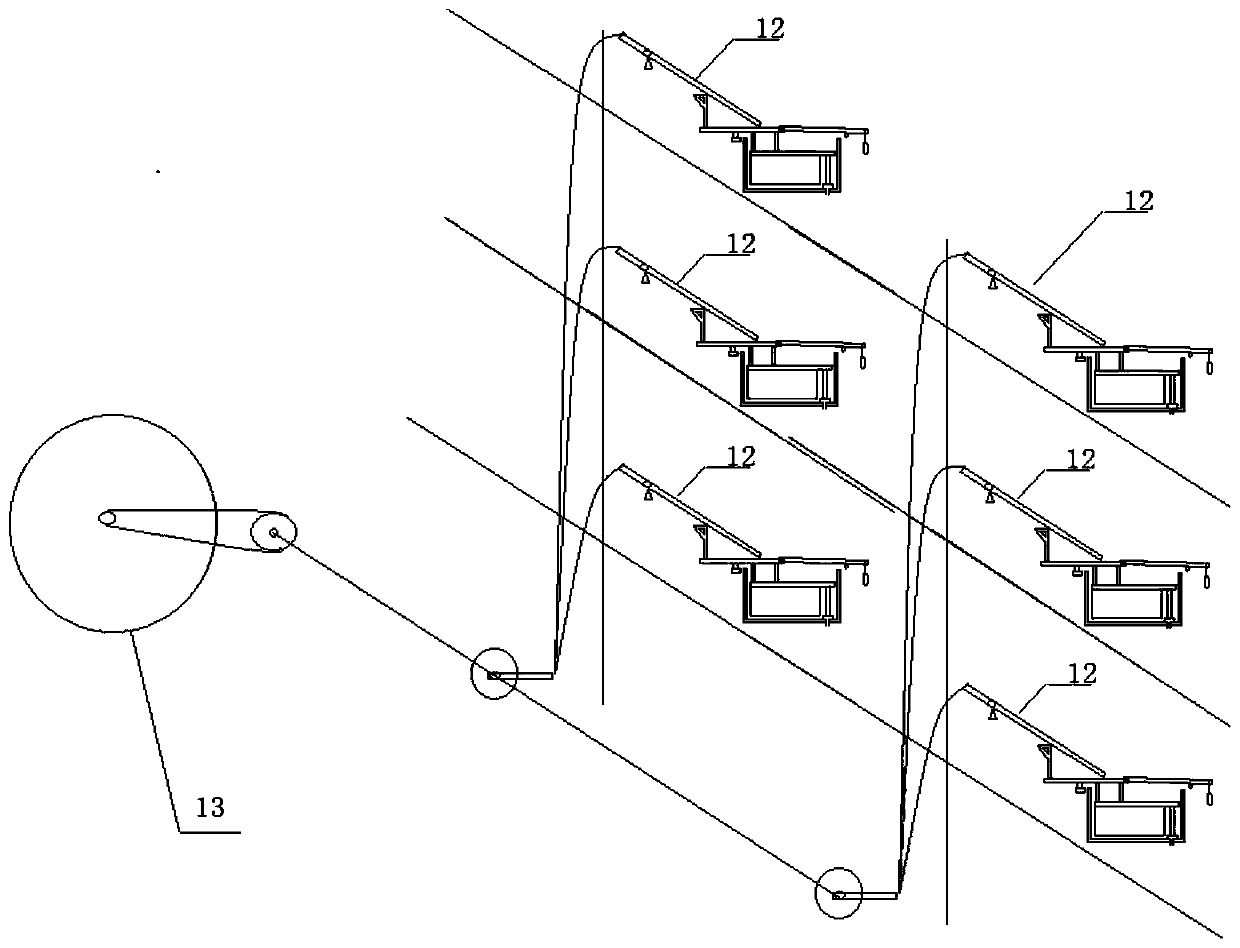

[0038] see figure 2 and image 3 , this example is the expansion of the above-mentioned embodiment 1, the tower-type combined operation method, and the method includes the following steps.

[0039] 1. The water tank described in Embodiment 1 of the method of the present invention, including a complete set of driving components, is stacked and placed in a well-shaped tower structure.

[0040] 2. Corresponding to each layer of driving components, set up a separate seesaw (12).

[0041] 3. Connect the drain pipe of the upper water tank to the water inlet of the lower water tank.

[0042] Water injection in the upper water tank pushes the corresponding seesaw (12) to move, and drives the inertial flywheel (13) of the seesaw flywheel power machine to rotate.

[0043] When the driving stroke of the upper layer is completed, the water tank is drained into the lower water tank, and the lower water tank relays to push the corresponding seesaw (12) to move, so that the inertial flyw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com