Conductive slip ring based on gallium-based liquid metal

A technology of liquid metal and conductive slip rings, which is applied in conductive slip ring equipment and the field of conductive slip rings based on gallium-based liquid metals. It can solve problems such as poor contact, reduced service life of slip rings, and severe sliding friction, and achieve electrical characteristics. Stable, easy to process and manufacture, low rotation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

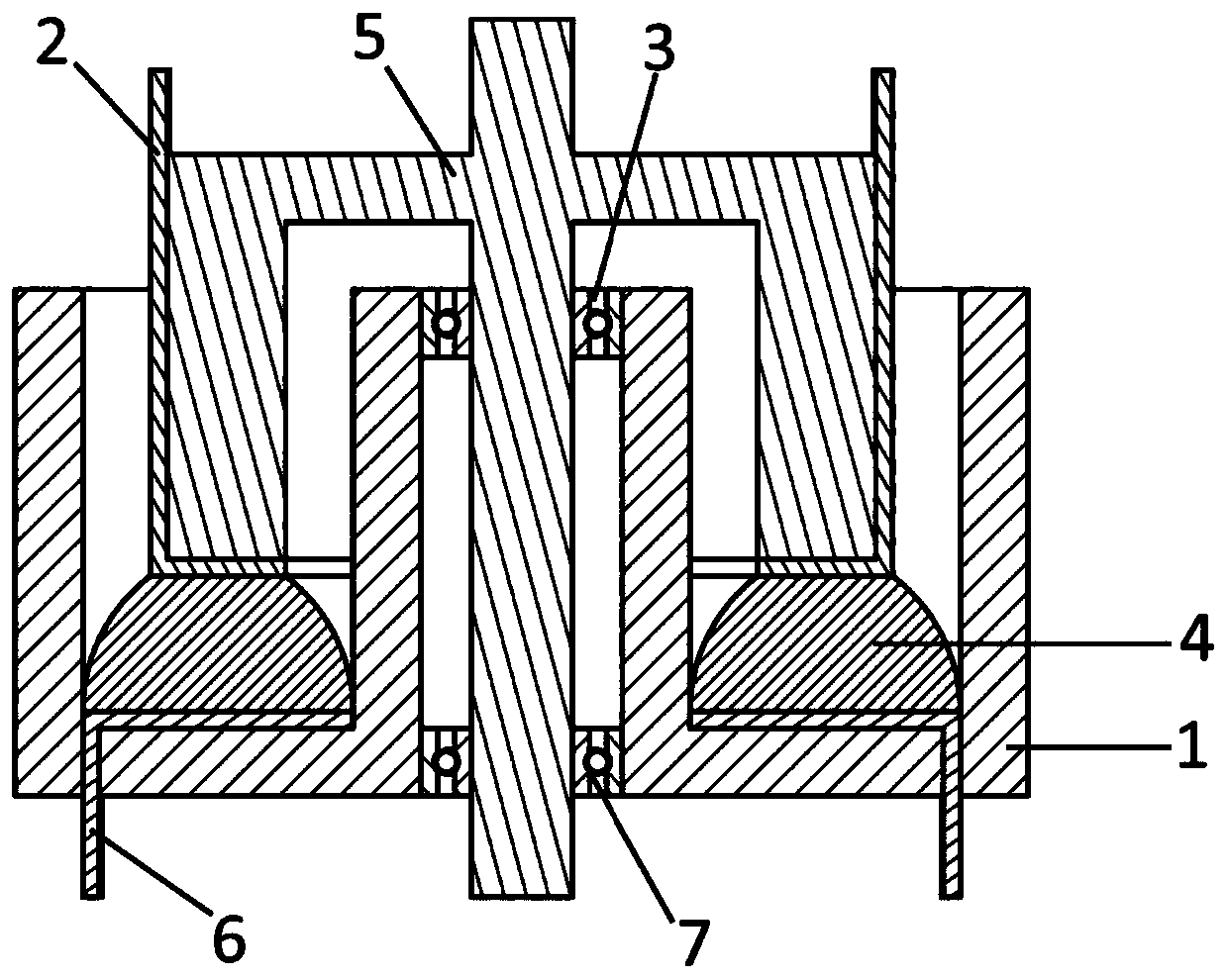

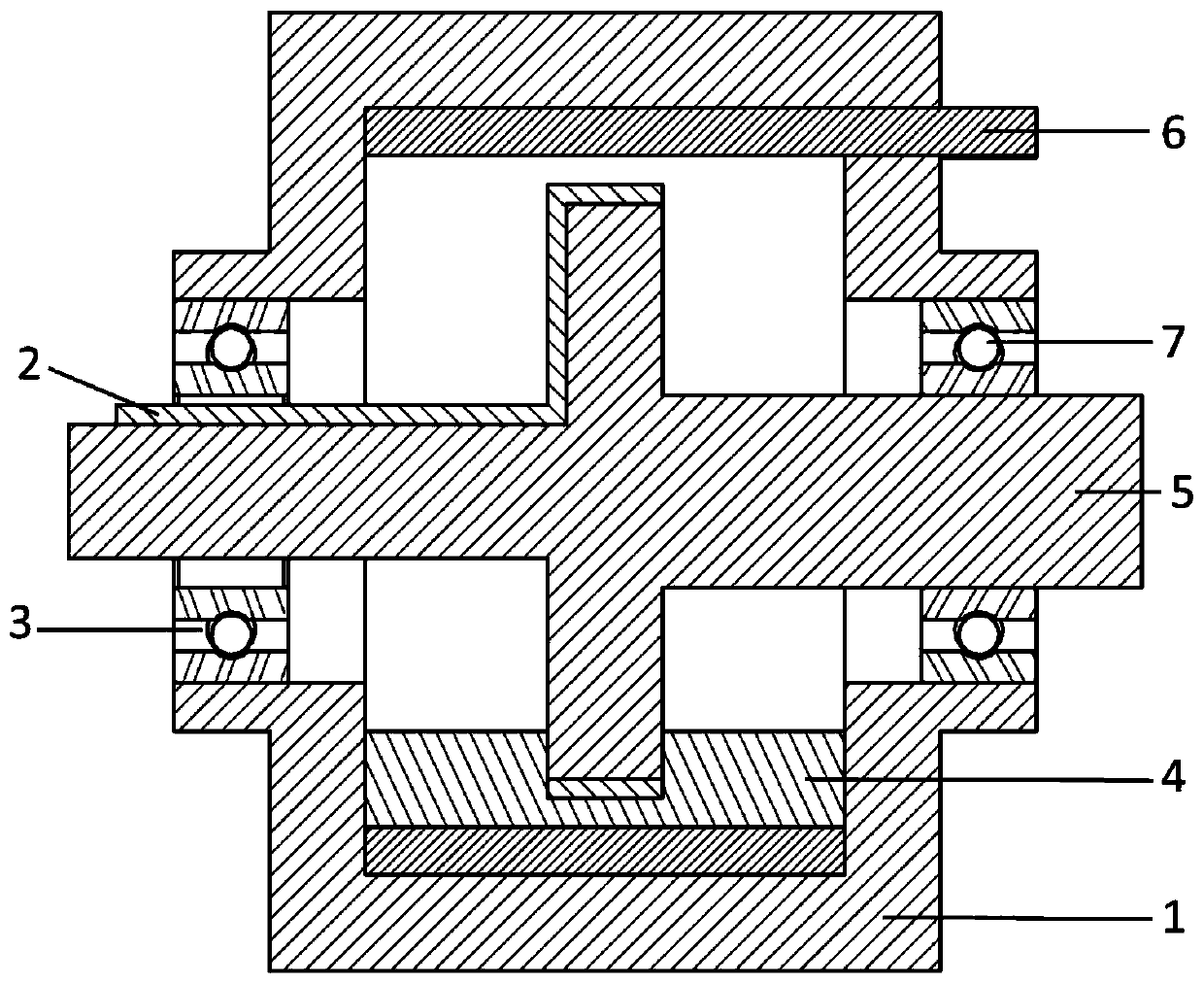

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] like figure 1 , 2 As shown, the present invention discloses two conductive slip rings based on gallium-based liquid metal, that is, a horizontal plane rotating conductive slip ring and a vertical plane rotating conductive slip ring including a stator 1, a first ball bearing 3, a second ball bearing 7, Rotor electrode 2 , gallium-based liquid metal 4 , stator electrode 6 , and rotor 5 . Among them, the rotor electrode 2 in the horizontally rotating conductive slip ring based on gallium-based liquid metal is a ring-shaped copper sheet, which is fixed on the bottom of the tubular structure of the rotor 5 . The rotor electrode 2 of the vertically rotating conductive slip ring based on gallium-based liquid metal is a circular tubular structure fixed on the disc side of the disc structure of the rotor 5 with a rotating shaft.

[0023] The stator e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com