Annular multistage sedimentation tank for sewage treatment

A technology for sewage treatment and sedimentation tank, which is applied to sedimentation tank, feeding/discharging device of sedimentation tank, sedimentation separation, etc., which can solve the problems of affecting drainage process, high labor intensity of manual cleaning, affecting sedimentation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

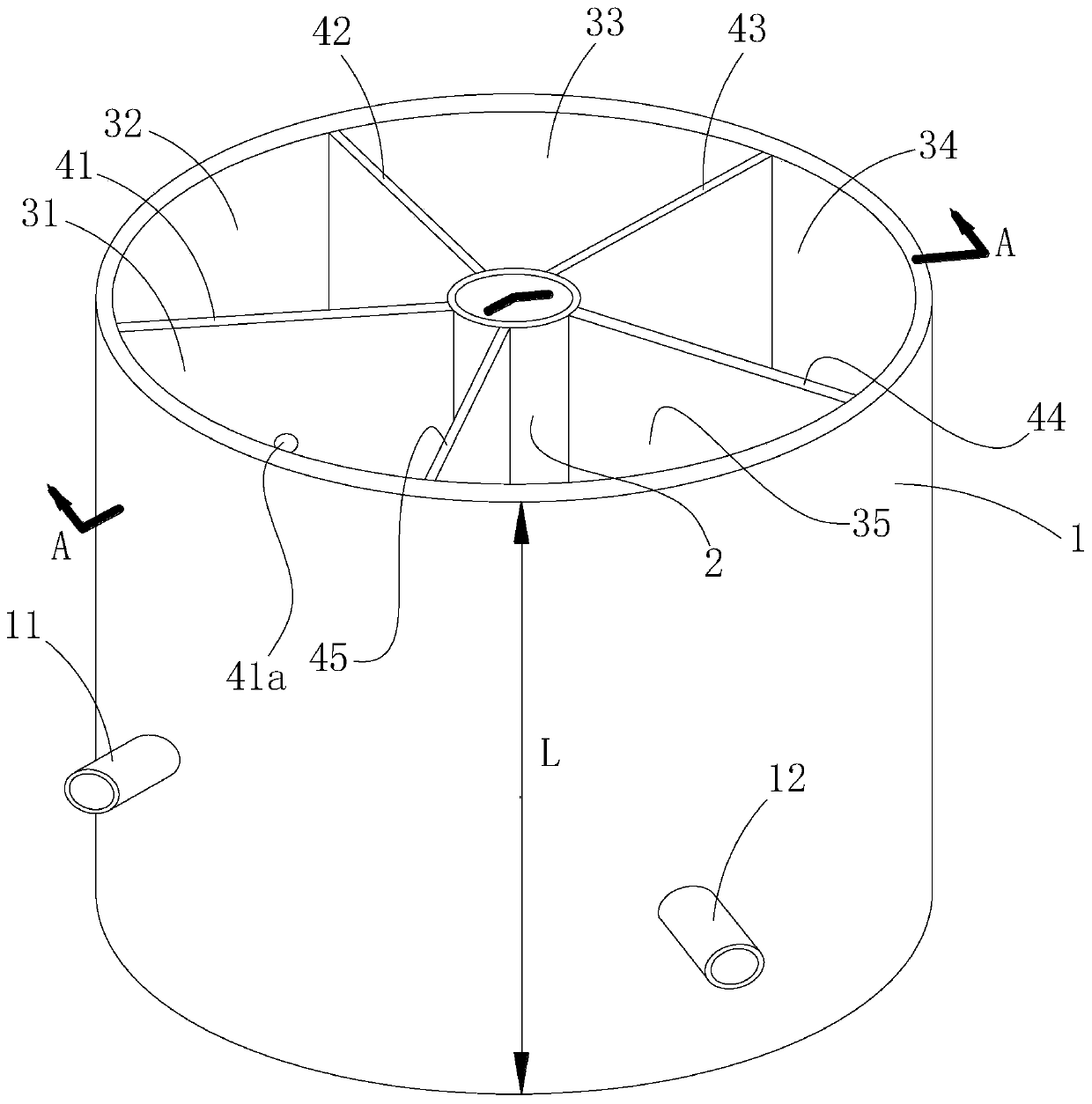

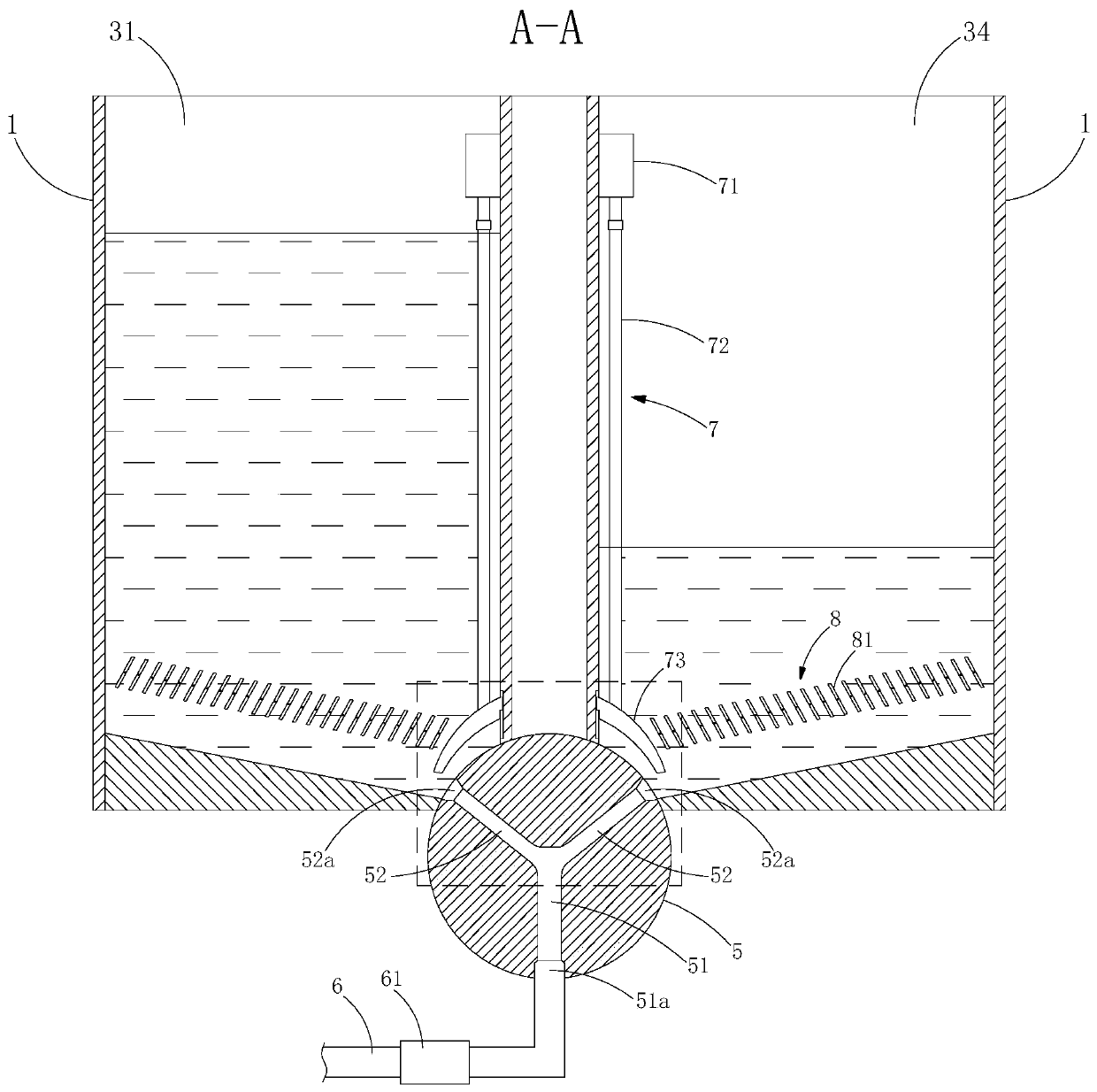

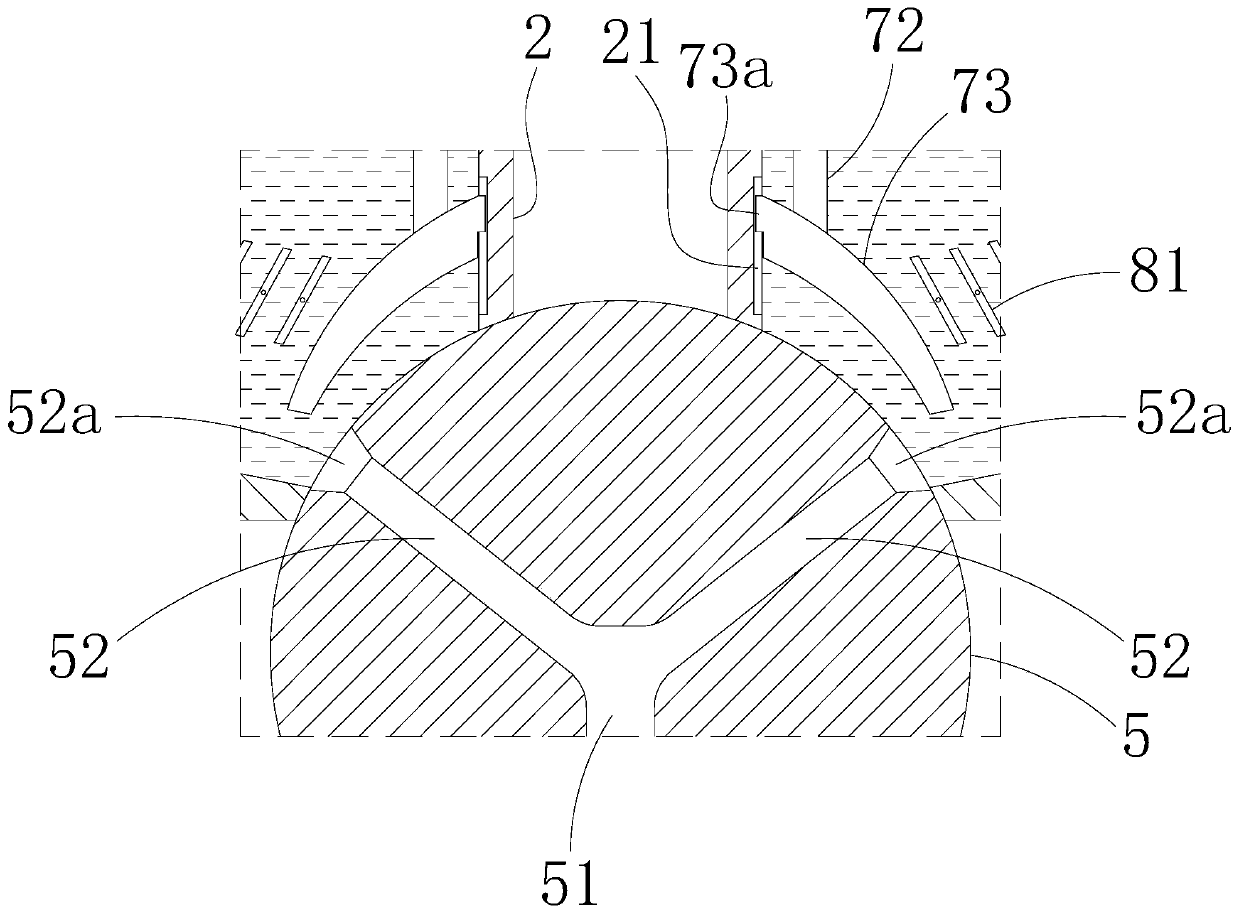

[0057] Such as Figure 1-Figure 6 As shown, this embodiment provides an annular multi-stage settling tank for sewage treatment, which includes an annular outer wall 1, a central column 2, five settling tanks, a sewage channel collection device 5, a sludge conduit 6, and a sewage inlet Port adjustment assembly 7 and anti-disturbance assembly 8.

[0058] The annular outer wall 1 is a closed annular wall made of bricks, and its height is L, such as figure 1 shown; and generally, the inner diameter of the annular outer wall 1 is not less than 1.5m.

[0059] The central column 2 is located in the center of the annular outer wall 1 and is coaxial with the annular outer wall 1. The central column 2 is a hollow structure and is made of concrete, such as figure 1 shown; and generally, the outer diameter of the central column 2 is not greater than 50cm, and the inner diameter is not less than 10cm.

[0060] Described five settling tanks are respectively the first-level settling tank ...

Embodiment 2

[0071] The present embodiment provides a kind of method utilizing the circular multistage settling tank of embodiment 1 to filter sewage, and it comprises the following steps:

[0072] S1, adjust the flow regulating valve, so that the flow regulating valves of the water inlet pipe 11, the first communicating pipe 41a, the second communicating pipe 42a, the third communicating pipe 43a and the fourth communicating pipe 44a are opened and the flow rates are kept consistent, and they are closed at the same time The flow regulating valve of the drain pipe 12;

[0073] S2, the sewage to be filtered is introduced into the first settling tank 31 from the water inlet pipe 11; after the sewage enters the first settling tank 31, it will flow into subsequent settling tanks along the respective connecting pipes 41a, 42a, 43a, 44a;

[0074] S3, when the liquid level in the five-stage settling tank 35 rises to h lower than the fourth connecting pipe 44a, close the flow regulating valve of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com