Ultralow noble metal content catalyst and preparation method and application thereof

A precious metal and catalyst technology, applied in the field of ultra-low precious metal content catalyst and its preparation, can solve the problems of short service life, large loading capacity, poor deactivation resistance, etc., and achieve long service life, strong deactivation resistance, good The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

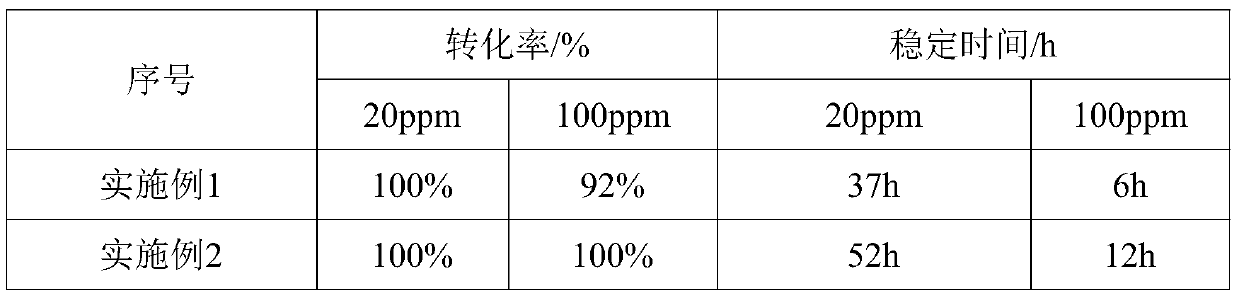

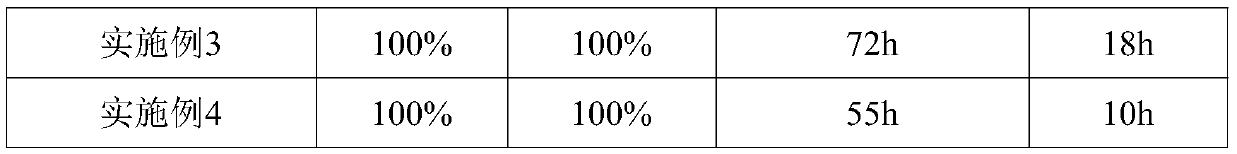

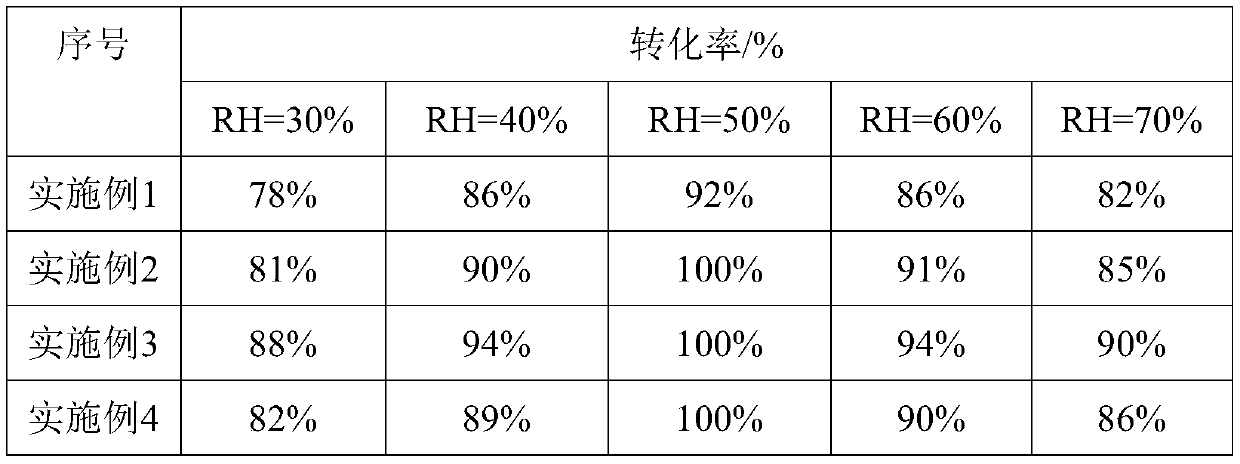

Examples

Embodiment 1

[0039] A preparation method of an ultra-low noble metal content catalyst, comprising the steps of:

[0040] S1. Preparation of carrier R-TiO 2 : Sodium borohydride and TiO 2 After mixing, keep at 300 °C for 30 min to remove unreacted sodium borohydride to obtain the carrier R-TiO 2 , the mass ratio of sodium borohydride and P25 is 1:4

[0041] S2. Preparation of ultra-low precious metal content catalyst: weigh 1g carrier R-TiO 2 , 0.0025gPd(NO 3 ) 2 Mix and stir after dissolving, NaBH 4 solution was added to the mixture solution (nNaBH 4 / nPd=20:1), reduction for 2 hours, the reduction temperature is 25°C, after the stirring is completed, the mixture is dried in a water bath at 80°C, and the obtained powder is dried overnight at 80°C, and the obtained catalyst is recorded as 0.1 Pd / R-TiO 2 , Pd loading is 0.1% by mass.

Embodiment 2

[0043] A preparation method of an ultra-low noble metal content catalyst, comprising the steps of:

[0044] S1. Preparation of carrier R-TiO 2 : Sodium borohydride and TiO 2 After mixing, keep at 300 °C for 30 min to remove unreacted sodium borohydride to obtain the carrier R-TiO 2 , the mass ratio of sodium borohydride and P25 is 1:4

[0045] S2. Preparation of ultra-low precious metal content catalyst: weigh 1g carrier R-TiO 2 , 0.0063gPd(NO 3 ) 2 Mix and stir after dissolving. After the stirring is completed, the mixture is dried in a water bath at 80°C. After drying the obtained powder at 80°C overnight, it is subjected to hydrogen reduction treatment at 300°C for 30 minutes, and the gas flow rate is 500mL / min. The catalyst is recorded as 0.25Pd / R-TiO 2 , Pd loading is 0.25% by mass.

Embodiment 3

[0047] A preparation method of an ultra-low noble metal content catalyst, comprising the steps of:

[0048] S1. Preparation of carrier R-TiO 2 : Sodium borohydride and TiO 2 After mixing, keep at 300 °C for 30 min to remove unreacted sodium borohydride to obtain the carrier R-TiO 2 , the mass ratio of sodium borohydride and P25 is 1:4

[0049] S2. Preparation of ultra-low precious metal content catalyst: weigh 1g carrier R-TiO 2 , 0.0125gPd(NO 3 ) 2 Mix and stir after dissolving. After the stirring is completed, the mixture is dried in a water bath at 80°C. After drying the obtained powder at 80°C overnight, it is subjected to hydrogen reduction treatment at 300°C for 30 minutes, and the gas flow rate is 500mL / min. The catalyst is recorded as 0.5Pd / R-TiO 2 , Pd loading is 0.5% by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com