Curtain coating process of mobile phone rear cover and application of curtain coating process

A mobile phone back cover and flow coating technology, which is applied to the coating, the device for coating liquid on the surface, and special surfaces, etc., can solve the problems of uneven coating, increased material consumption, and uneven coating thickness. Clear image, excellent mirror effect, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1 provides a kind of flow coating process of mobile phone back cover, comprises the following steps:

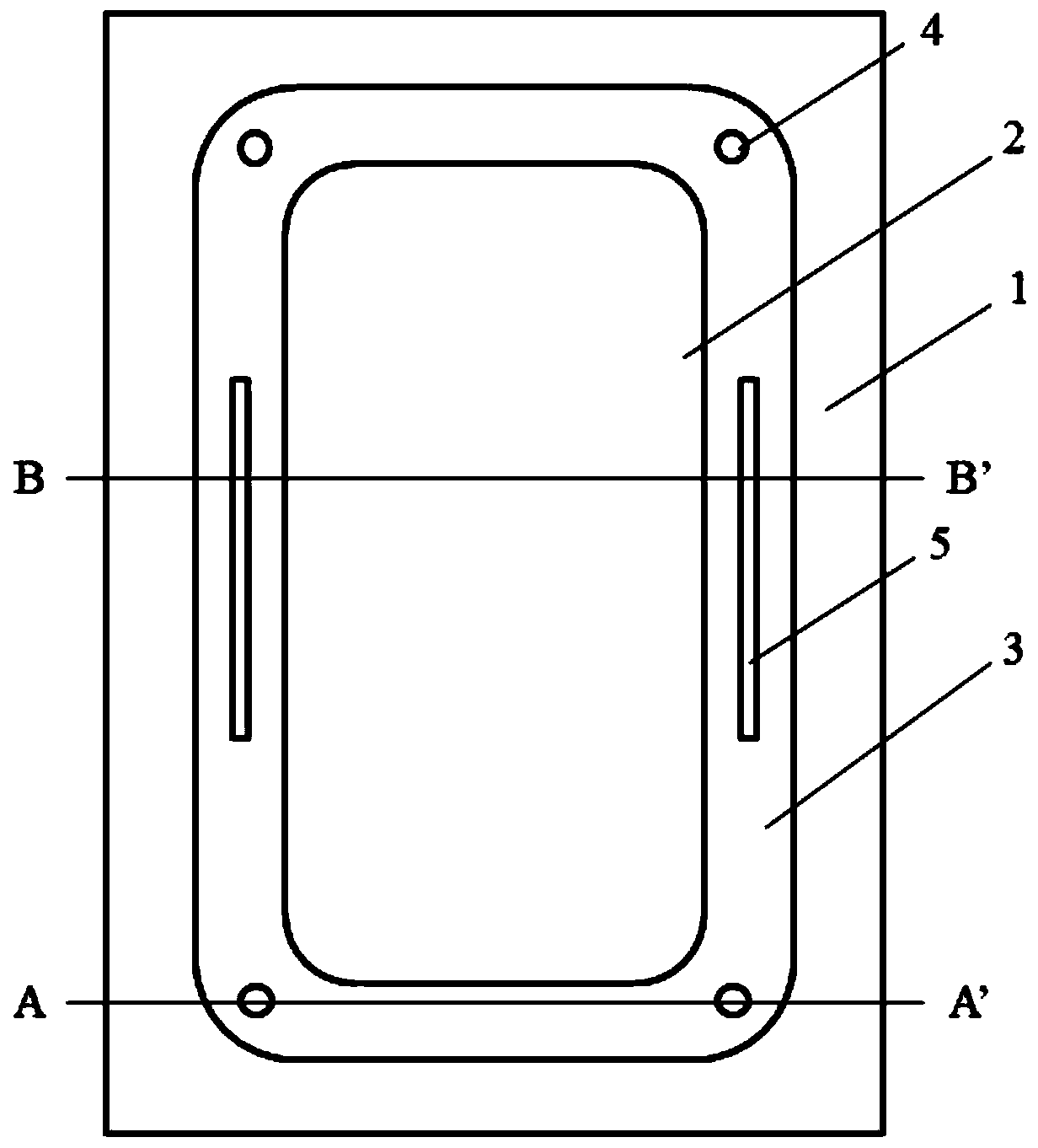

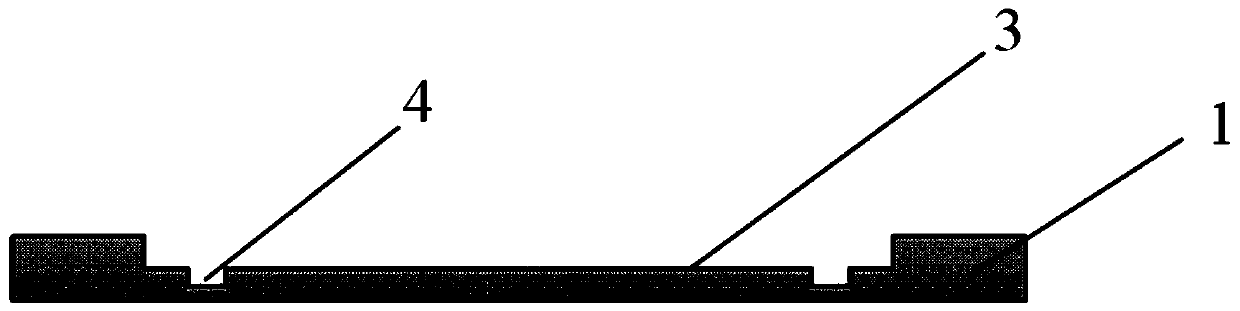

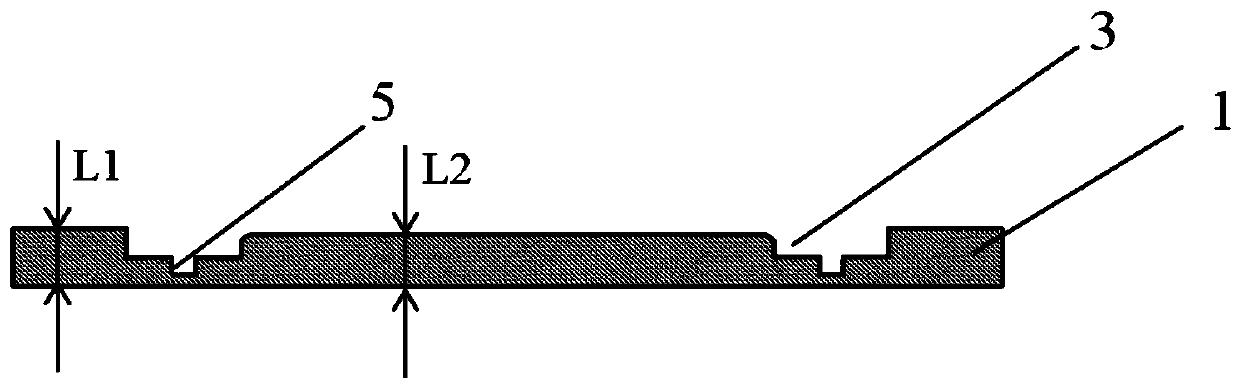

[0060] a. Put the back cover of the phone on the figure 1 on the protrusion 2 of the mold shown;

[0061] b. Spread the spray coating material on the back cover of the mobile phone, and stop the spray coating after the spray coating material is soaked in the square tank 3;

[0062] c. After the spray coating material is dry, cut along the edge of the mobile phone back cover and remove it from the mold to obtain the spray coated mobile phone back cover.

[0063] The raw materials for the preparation of the materials used in the step b include: 18 parts by weight of silicone resin (Wacker, SILRESREN 80), hybrid resin (Evonik Degussa, SILIKOPON EF, epoxy silicone hybrid resin) 18 parts by weight, dibutyl phthalate 18.65 parts by weight, anti-fingerprint additive (Shin-Etsu, KY-1023) 0.05 parts by weight, wetting agent (Dow Chemical, X-405) 0.2 parts by weight...

Embodiment 2

[0066] Embodiment 2 provides a kind of flow coating process of mobile phone back cover, comprises the following steps:

[0067] a. Put the back cover of the phone on the figure 1 on the protrusion 2 of the mold shown;

[0068] b. Spread the spray coating material on the back cover of the mobile phone, and stop the spray coating after the spray coating material is soaked in the square tank 3;

[0069] c. After the spray coating material is dry, cut along the edge of the mobile phone back cover and remove it from the mold to obtain the spray coated mobile phone back cover.

[0070] The raw materials for the preparation of the materials used in the step b include: 15 parts by weight of silicone resin (Wacker, SILRESREN 80), hybrid resin (Evonik Degussa, SILIKOPON EF, epoxy silicone hybrid Resin) 15 parts by weight, dibutyl phthalate 15 parts by weight, anti-fingerprint additive (Shin-Etsu, KY-1023) 0.05 parts by weight, wetting agent (Dow Chemical, X-405) 0.2 parts by weight, n...

Embodiment 3

[0073] Embodiment 3 provides a kind of flow coating process of mobile phone back cover, comprises the following steps:

[0074] a. Put the back cover of the phone on the figure 1 on the protrusion 2 of the mold shown;

[0075] b. Spread the spray coating material on the back cover of the mobile phone, and stop the spray coating after the spray coating material is soaked in the square tank 3;

[0076] c. After the spray coating material is dry, cut along the edge of the mobile phone back cover and remove it from the mold to obtain the spray coated mobile phone back cover.

[0077] The preparation raw materials of the materials used in the step b include: silicone resin (Wacker, SILRESREN 80) 20 parts by weight, hybrid resin (Evonik Degussa, SILIKOPON EF, epoxy silicone hybrid resin) 20 parts by weight, dibutyl phthalate 20 parts by weight, anti-fingerprint additive (Shin-Etsu, KY-1023) 0.06 parts by weight, wetting agent (Dow Chemical, X-405) 0.24 parts by weight, non Ionic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com