Transportation system for forging blank transportation

A transportation system and billet technology, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve problems such as high labor intensity, safety hazards, billet drop, etc., and improve production efficiency , Enhanced stability, stable and reliable feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

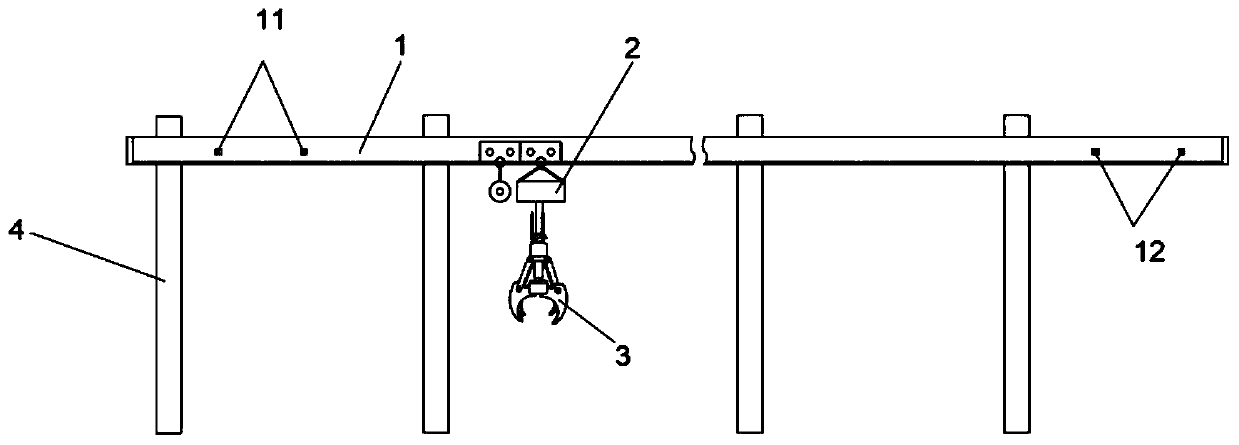

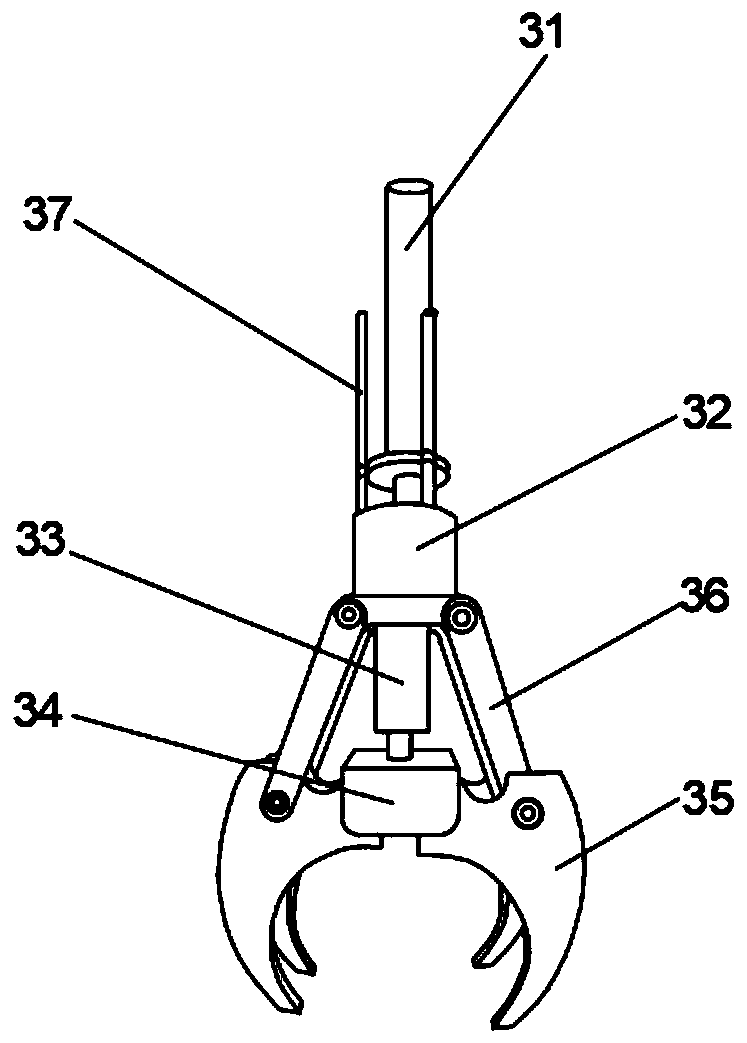

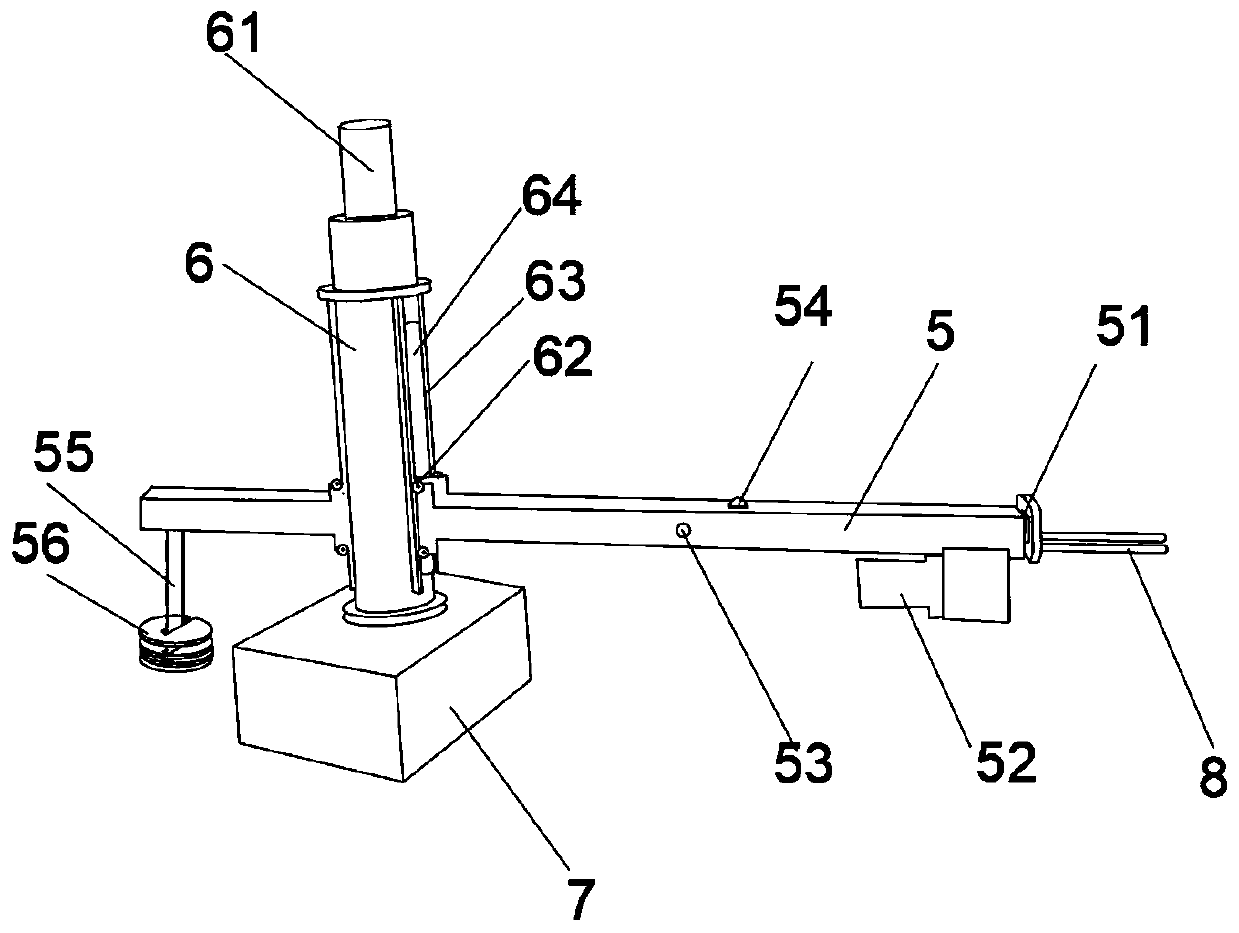

[0031] Such as figure 1 with 4As shown, the transportation system for forging billet transportation provided in this specific embodiment includes a feeding device for transferring the billet to the billet processing area, a transportation track 1 arranged between the billet output area and the feeding device, and a device The electric hoist 2 on the transportation track 1 is fixedly connected to the lower part of the electric hoist 2 with a mechanical gripper 3 for clamping and transferring the billet, and the mechanical gripper 3 is hung on the lower part of the electric hoist 2 . The transportation track 1 is an I-shaped steel, and the material is common, which is convenient for processing and production. The transportation track 1 is supported by the support frame 4 .

[0032] The electric hoist 2 is provided with a Hall switch, and two first magnets 11 for sensing with the Hall switch to control the opening and closing of the Hall switch are arranged at intervals on the p...

Embodiment 2

[0050] see Figure 5 , the present invention also provides another feeding device. In this embodiment, the transportation system for forging blank transportation is substantially the same as the transportation system for forging blank transportation in Embodiment 1, the difference is: The feeding device is a chain conveyor, and the chain conveyor is arranged between the peripheral friction press and the peripheral die forging hammer.

[0051] The feeding device in Embodiment 1 and the feeding device in this embodiment can be selected according to the on-site conditions. In this embodiment, the mechanical jaws transport the blank to the feeding device provided in this embodiment, that is, on the chain conveyor. The forward and reverse of the chain conveyor can transport the billet to the friction press or the peripheral die forging hammer, which meets the needs of different working conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com