Car engine connecting rod bimetal investment casting process

A technology of automobile engine and investment casting, which is used in metal processing equipment, connecting rods, manufacturing tools, etc. to achieve the effects of high strength, improved castability, and higher qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

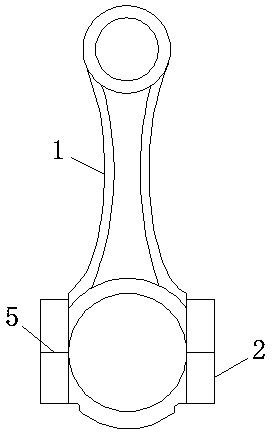

[0022] The concrete steps of the automobile engine connecting rod bimetal investment casting process of the present invention are as follows:

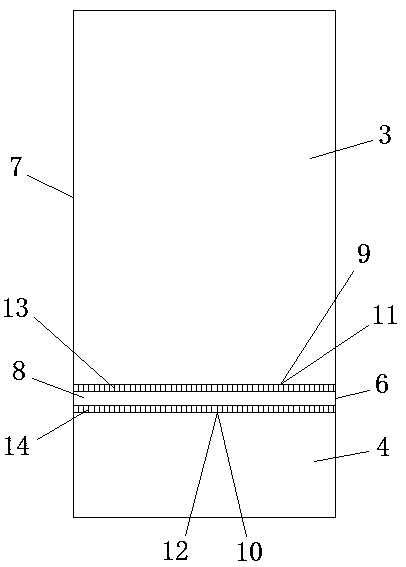

[0023] S1: Combining the cavity 3 of the connecting rod body and the cavity 1 of the cover body into a bimetallic investment casting module 7;

[0024] S2: form the split groove 8 in the bimetal investment casting module at the contact part of the connecting rod body cavity 3 and the cover body cavity 4;

[0025] S3: The two ends of the separation plate 13 and the separation plate 2 14 should be locked in the groove 1 9, the groove 2 10, the groove 3 11 and the groove 4 12 in the split groove 8 by sliding;

[0026] S4: injecting the splitting material of the connecting rod body into the splitting groove 8 for molding;

[0027] S5: eject the separation plate one 13 from the first groove 9 and the third groove 11

[0028] S6: injecting the connecting rod body molding material into the connecting rod body cavity 3 for molding;

[0029]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com