Automatic tube bundle penetrating device and method for tube-shell type heat exchanger equipment

A shell-and-tube heat exchanger, automatic threading technology, applied in metal processing equipment, assembly machines, metal processing, etc., to achieve a wide range of applications, reduce friction, and improve the efficiency of threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

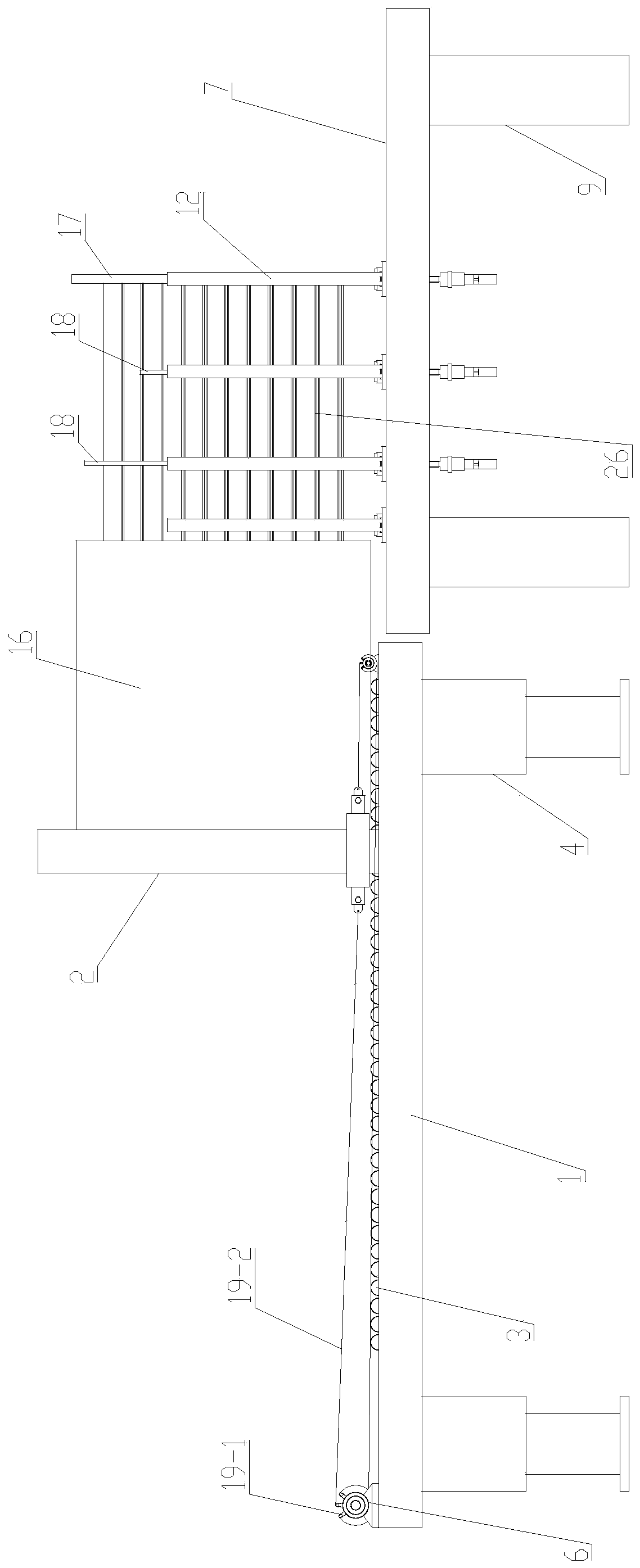

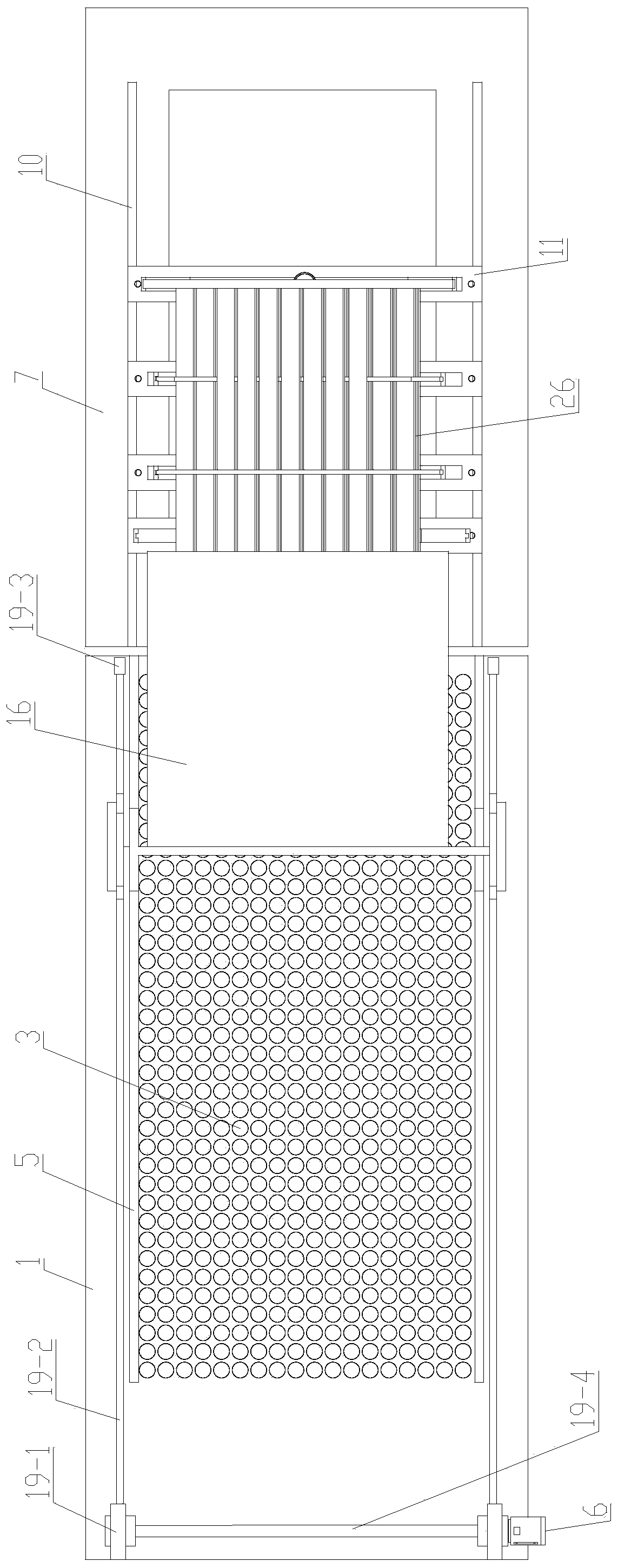

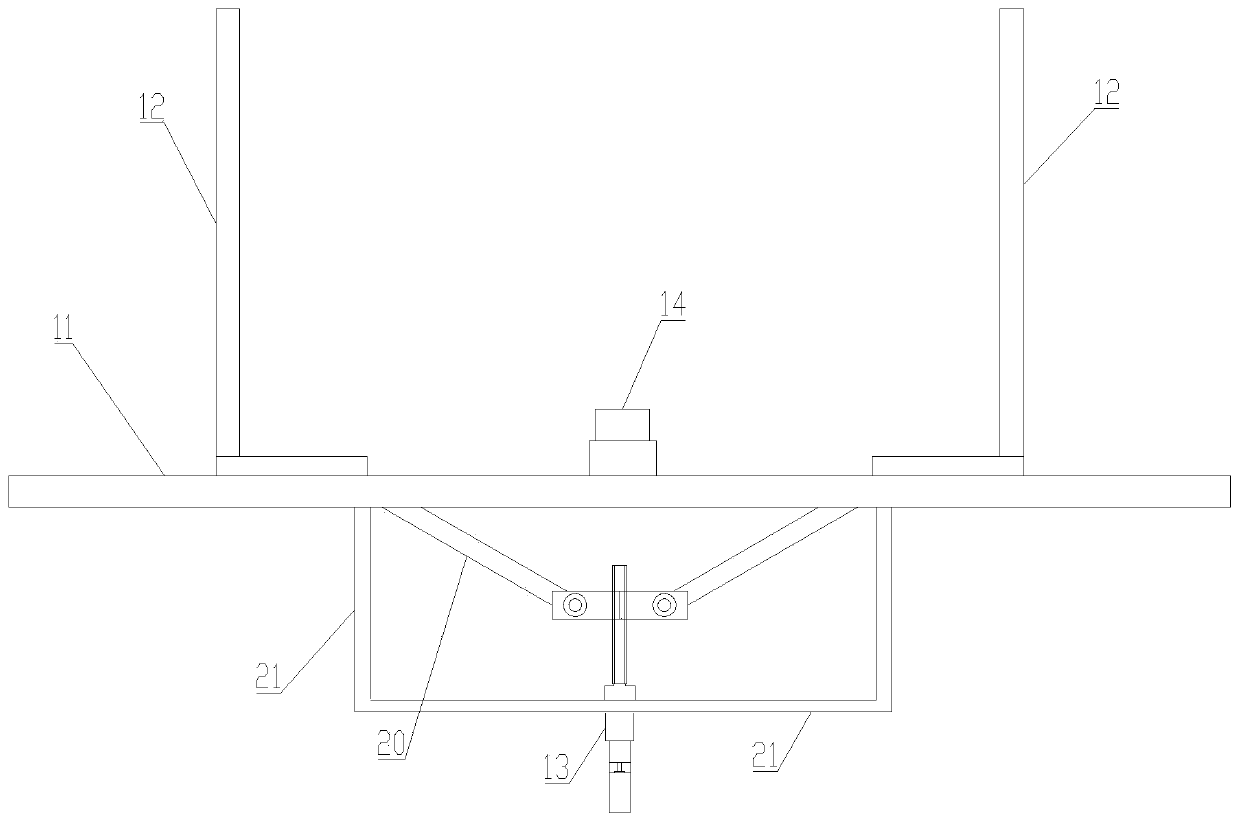

[0060] Such as Figure 1 to Figure 5 As shown, the present invention includes a lifting platform 1 and a fixed platform 7 that cooperate with each other. The lifting platform 1 is provided with a movable baffle 2 for pushing the cylinder body 16 of the heat exchanger to move, and the movable baffle 2 slides Installed on the lifting platform 1, the lifting platform 1 is provided with a baffle driving mechanism for driving the translation of the movable baffle 2, and the lifting platform 1 is also provided with a mechanism for reducing the gap between the cylinder body 16 and the lifting platform 1. The ball matrix 3 of the friction force, the fixed platform 7 is provided with a plurality of movable supports for fixing the tube sheets 17 and baffles 18 of the heat exchanger, and the movable supports are made of rigid movable plates 11 A U-shaped bracket composed of two rigid movable arms 12, the rigid movable plate 11 is slidably installed on the fixed platform 7, a jacking mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com