Assembly line equipment for producing aluminum profiles

An assembly line and aluminum profile technology, which is applied in the direction of transportation, packaging, rollers, etc., can solve the problems of reducing the transmission efficiency of aluminum profiles, external damage of aluminum profiles, and collision of aluminum profiles, so as to avoid external damage, improve friction, The effect of increasing contact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] like Figure 1-Figure 5 Shown:

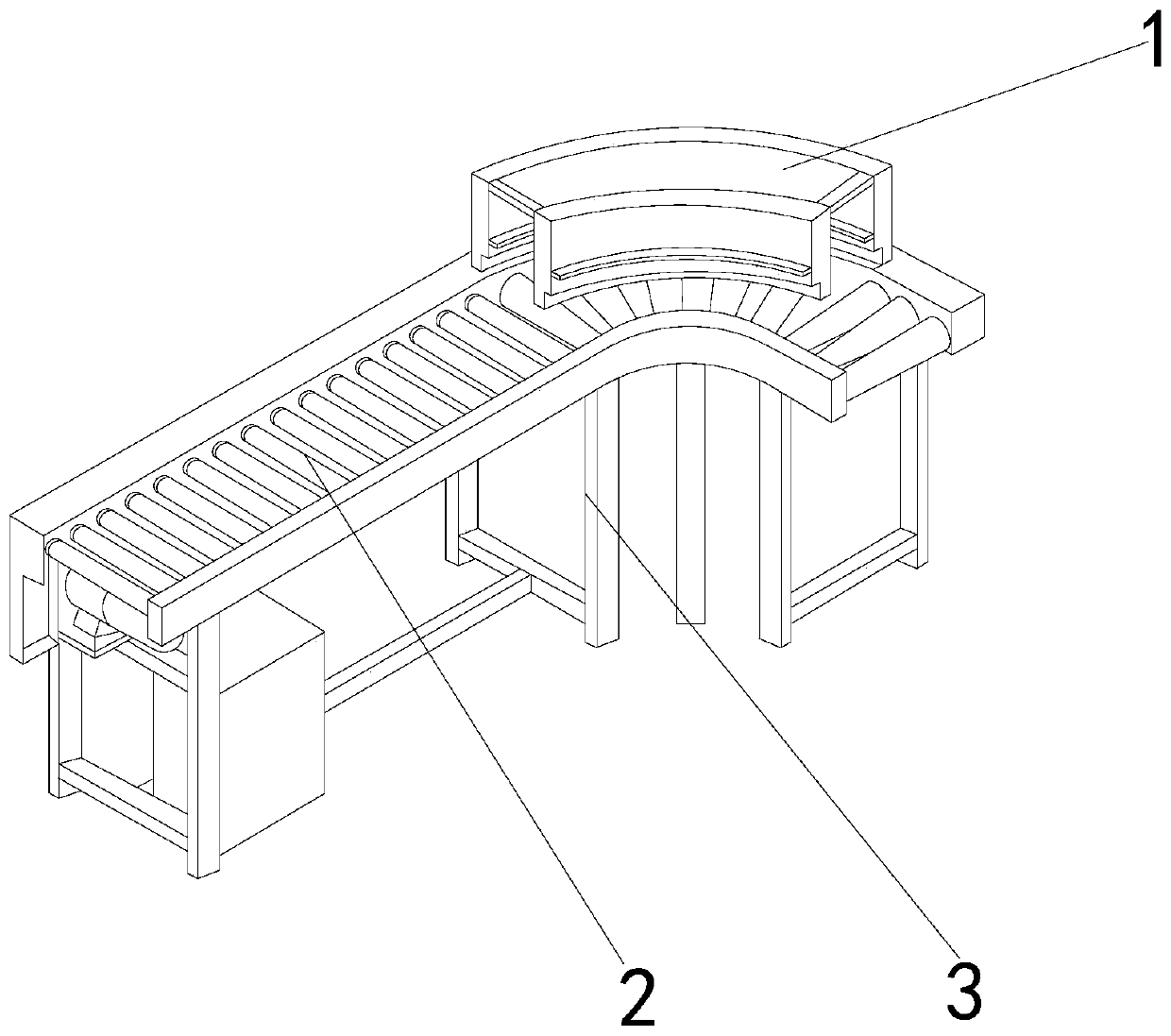

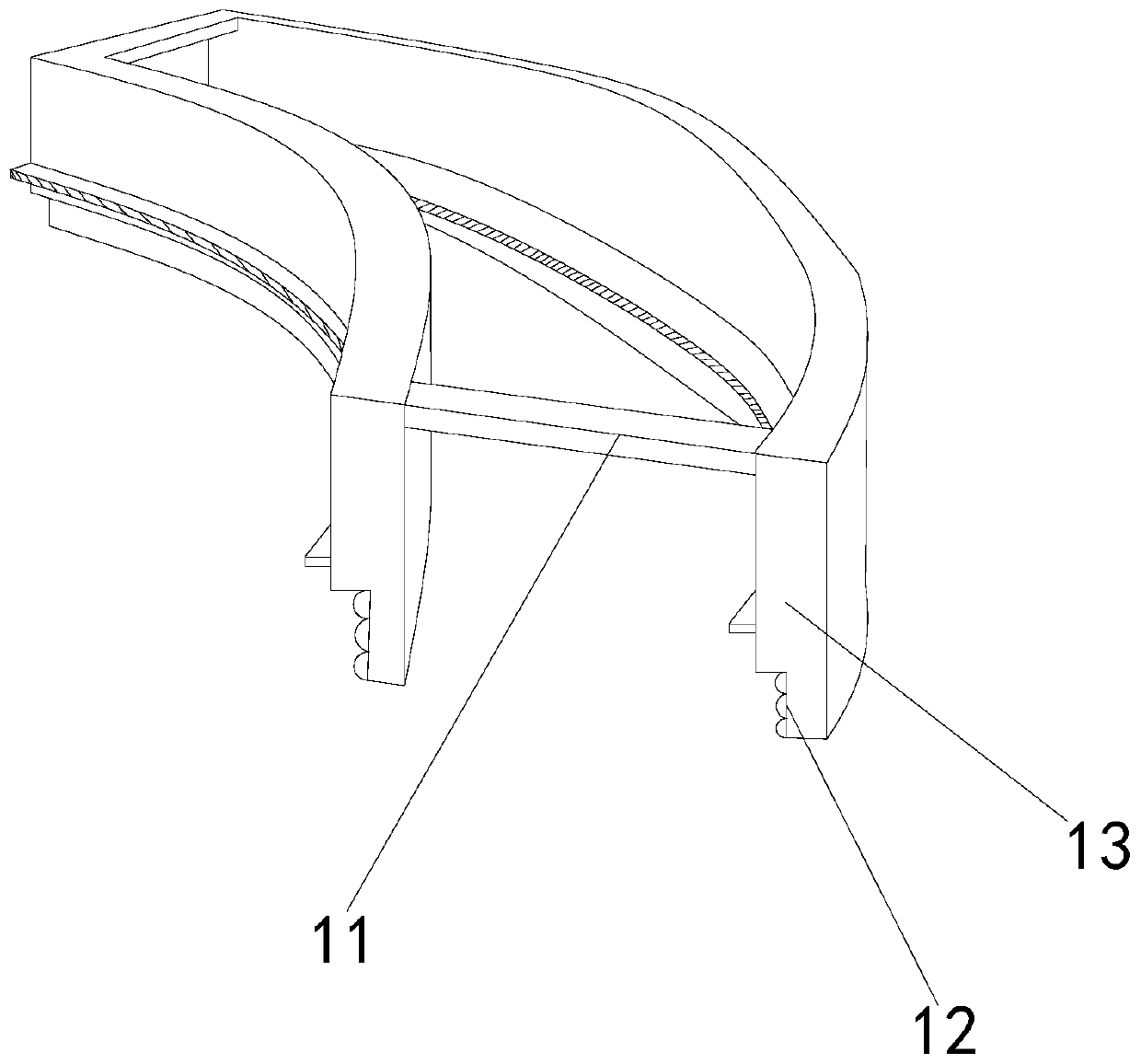

[0024] The present invention is an assembly line equipment for producing aluminum profiles. Its structure includes a bending device 1, a roller 2, and a fixing frame 3. The bending device 1 is embedded and installed on the upper right side of the fixing frame 3. The ends are installed on the inner sides of both ends of the fixed frame 3, the bending device 1 and the roller shaft 2 are parallel to each other, the bending device 1 is provided with a connecting rod 11, a sliding device 12, and a bending plate 13, and the two ends of the connecting rod 11 Welded on the inner side of the upper end of the curved plate 13, the sliding device 12 and the curved plate 13 are an integral structure, the lower end of the curved plate 13 is embedded and installed on the right upper end of the fixed frame 3, and the curved plate 13 is provided with two One, in a curved structure, slides the aluminum profile through the sliding device 12 at the lower e...

Embodiment 2

[0031] like Figure 6-Figure 7 Shown:

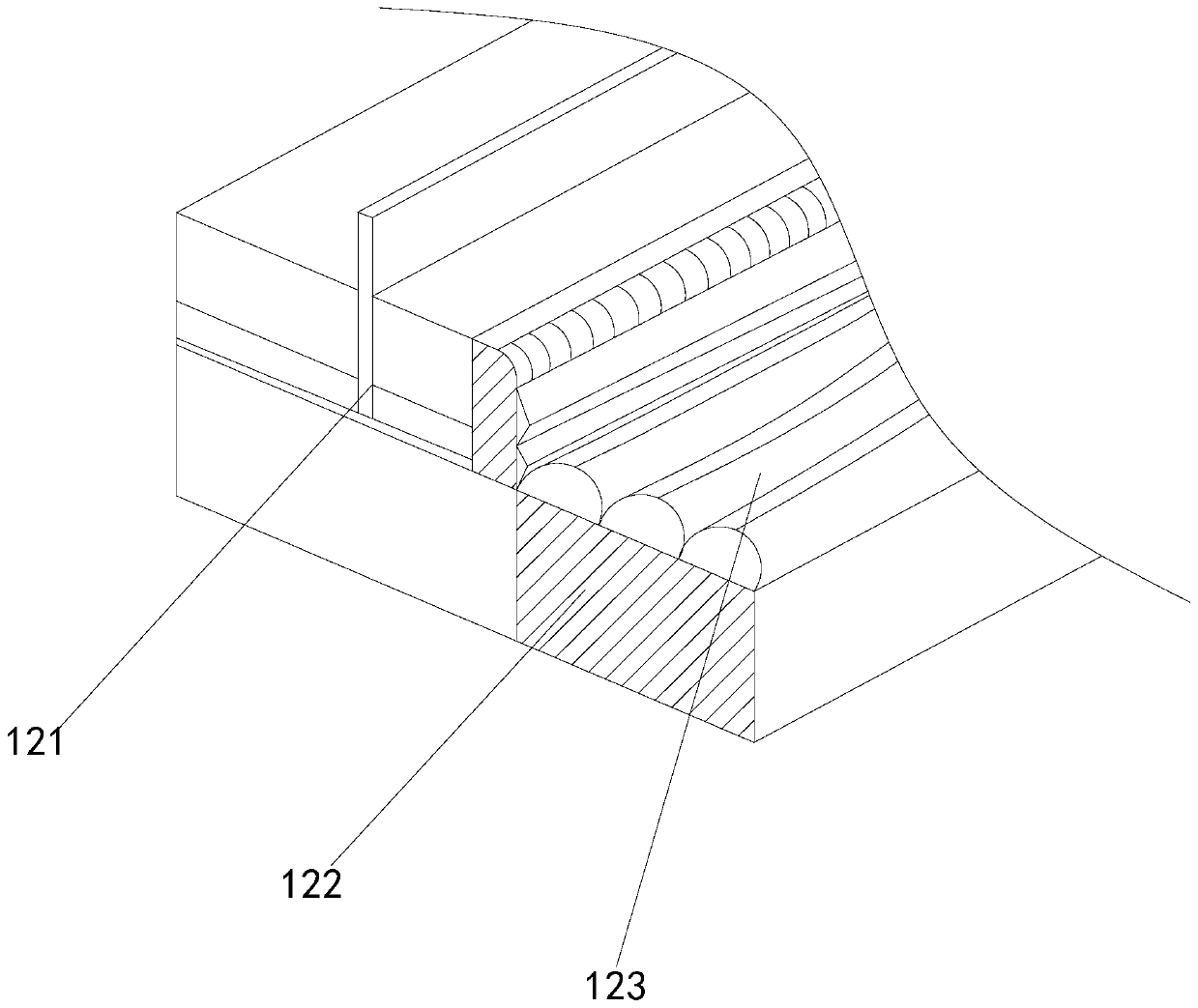

[0032] Wherein, the roller 2 is provided with a resistance mechanism 21, a power shaft 22, a friction shaft 23, and a rubber block 24. The resistance mechanism 21 is attached to the outer surface of the power shaft 22, and the rubber block 24 is attached to the friction shaft. 23, the friction shaft 23 is embedded on both sides of the power shaft 22, the two ends of the power shaft 22 and the friction shaft 23 are embedded in the upper end of the fixed frame 3, and the resistance mechanism 21 is provided with five , with the power shaft 22 as the center evenly surrounding its surface, the diameter of the resistance mechanism 21 is larger than that of the rubber block 24, and the pressure of the aluminum profile on the roller 2 is increased through the high level difference, and the contact between the aluminum profile and the roller 2 is improved intensity.

[0033] Wherein, the resistance mechanism 21 is provided with a rubber plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com