Glass cutting process

A glass cutting and process technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of laborious, time-consuming, complex process steps, etc., and achieve high cutting efficiency, ensure cutting quality, and simple steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

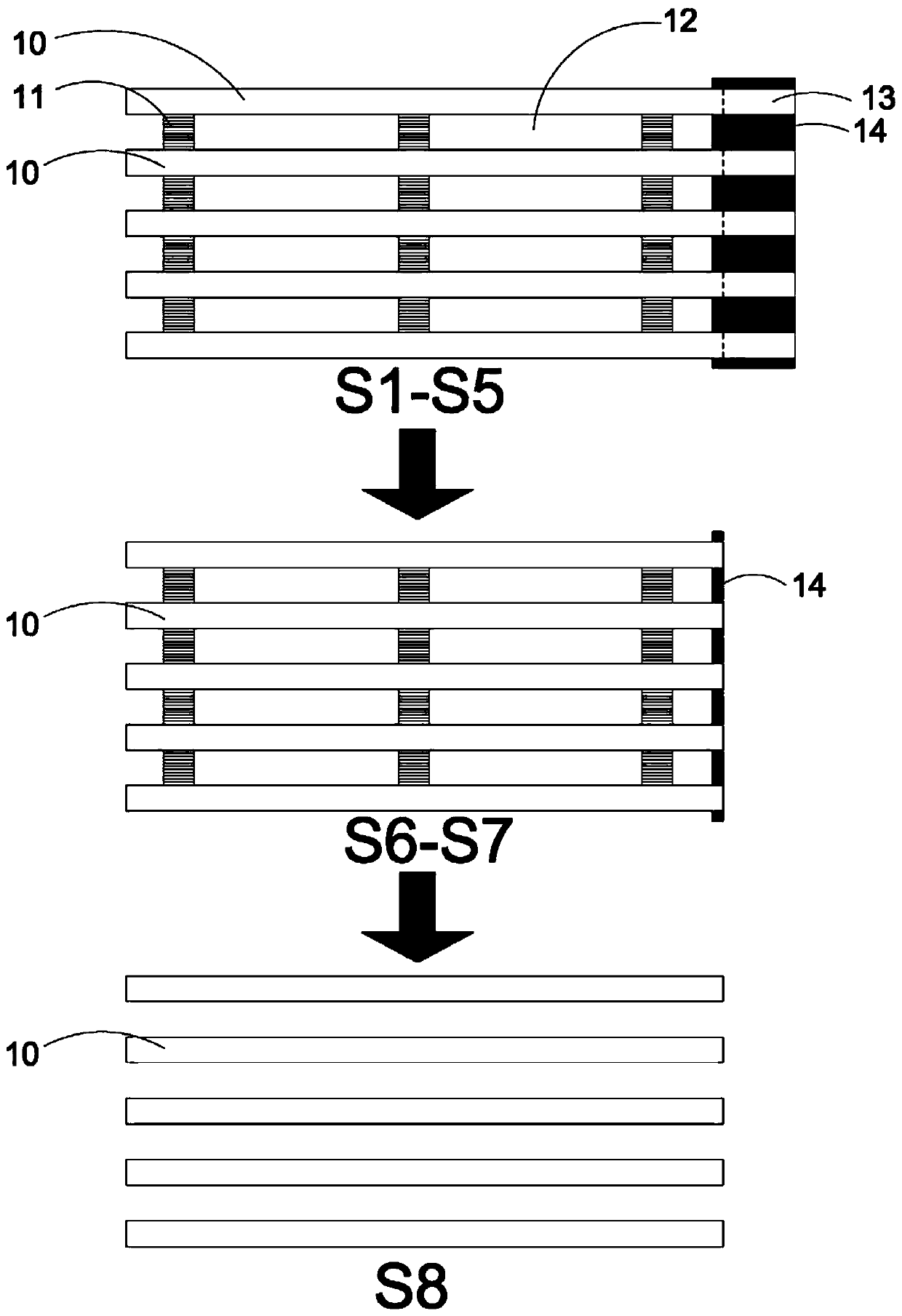

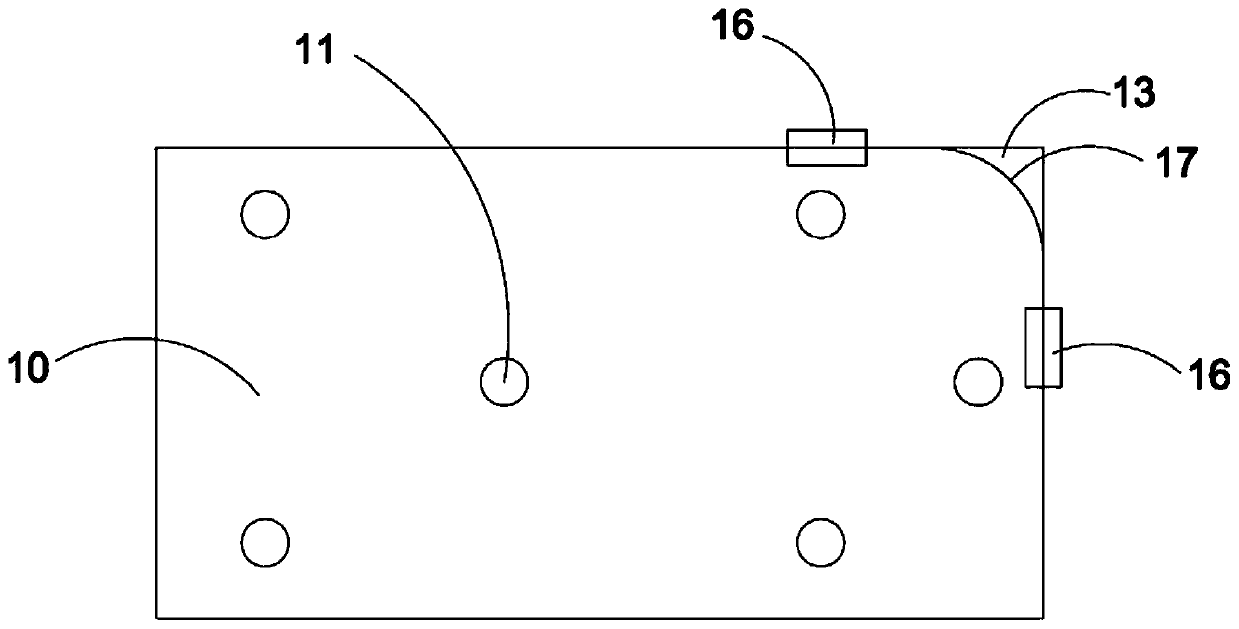

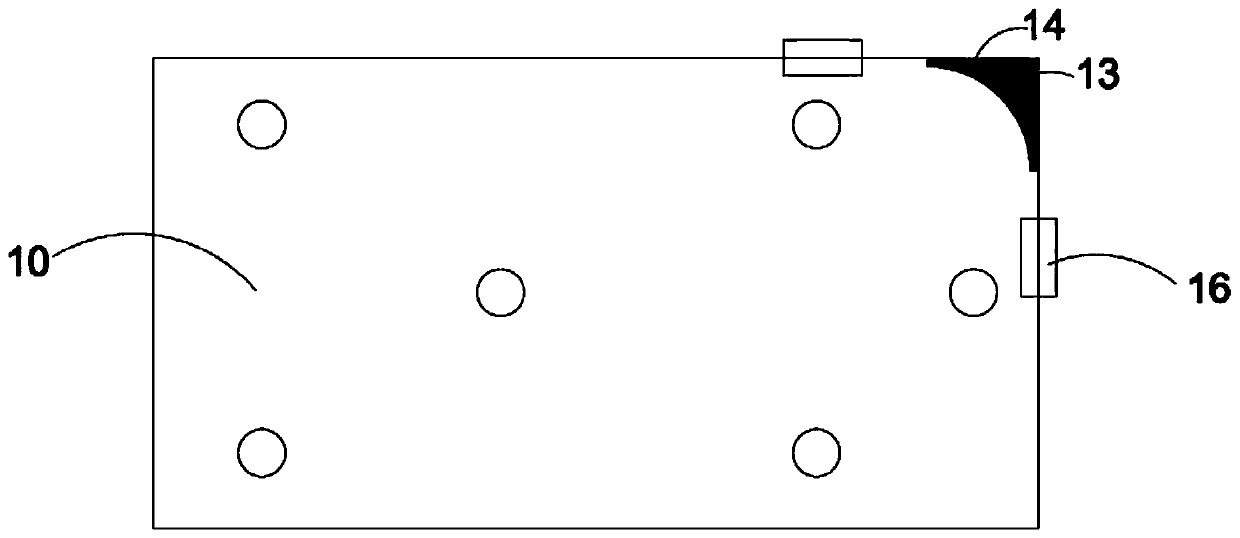

[0031] First implementation: see Figure 1-4 Shown, a kind of glass cutting process comprises the following steps:

[0032] S1. Cleaning: wipe clean the pieces of glass to be cut;

[0033] S2. Marking: measure and mark the required radian at the corner of each glass to be cut;

[0034] S3. Stacking: Stack the glass 10 sequentially from bottom to top, so that the marks on each layer of glass overlap together, and a number of spacers 11 are set between adjacent upper and lower glasses to form a spacer 12; set a 90° angle The limit plate, under the limit function of the limit plate, stacks the glass in turn; the limit plate is formed by vertically connecting two surrounding plates; Sheet magnets of the same thickness are stacked. If you need to adjust the height of the compartment, you can adjust the number of magnet sheets accordingly;

[0035] S4. Compression: after the stacking of several layers of glass is completed, several layers of glass are clamped by the clamping seat...

no. 2 approach

[0041] Second embodiment: see Figure 5 Shown, a kind of glass cutting process comprises the following steps:

[0042] S1. Cleaning: wipe clean the pieces of glass to be cut;

[0043] S2. Marking: Measure the required radian at the corner of each glass to be cut and mark it out; paste double-sided tape 15 on the upper surface and lower surface of the position to be cut out of the glass mark, double-sided tape The area of is larger than the area of the position to be cut;

[0044]S3. Stacking: Stack the glass 10 sequentially from bottom to top, so that the marks on each layer of glass overlap together, and a number of spacers 11 are set between adjacent upper and lower glasses to form an interlayer 12; each layer of spacer Correspondingly, they are evenly distributed in the interlayer; the height block is made of stacked sheet magnets of the same thickness. If the height of the interlayer needs to be adjusted, the number of magnet pieces can be adjusted accordingly;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com