Red phosphorus adhesion device for matchhead processing

A technology of matchheads and red phosphorus, which is applied to matches and other fields, can solve the problems of cumbersome process and low work efficiency, and achieve the effects of simple operation, improved work efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be specifically described below in conjunction with the accompanying drawings.

[0026] first implementation

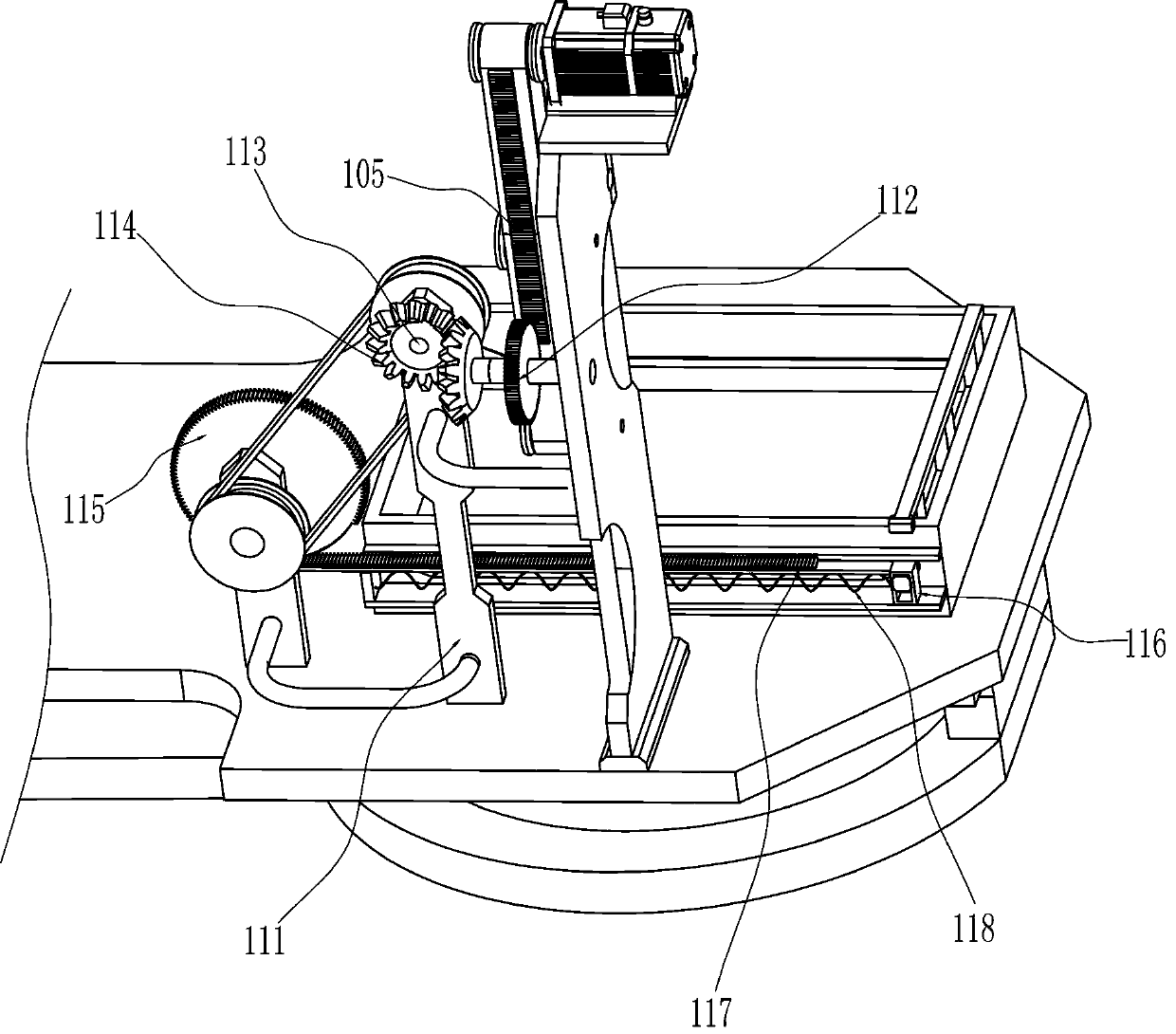

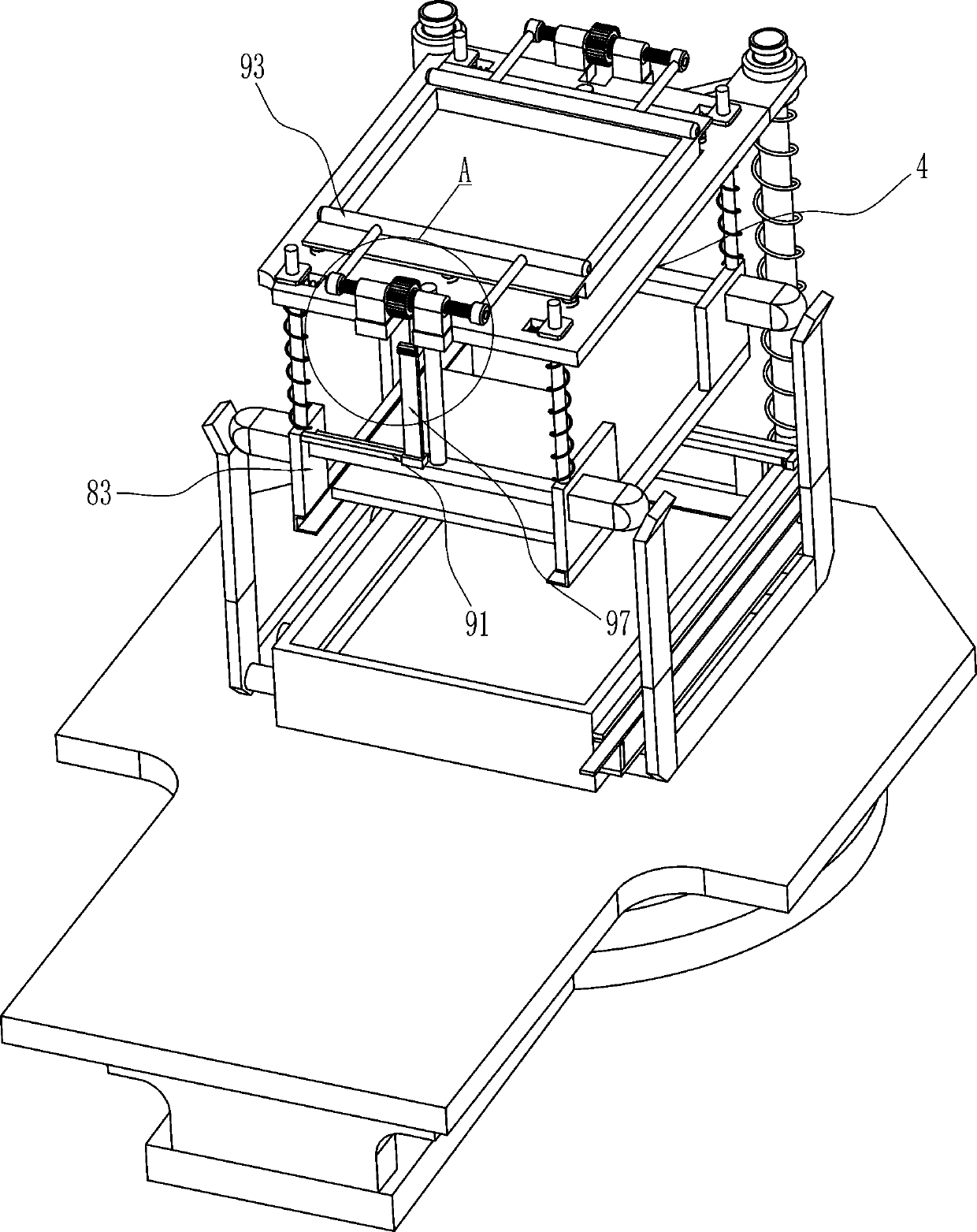

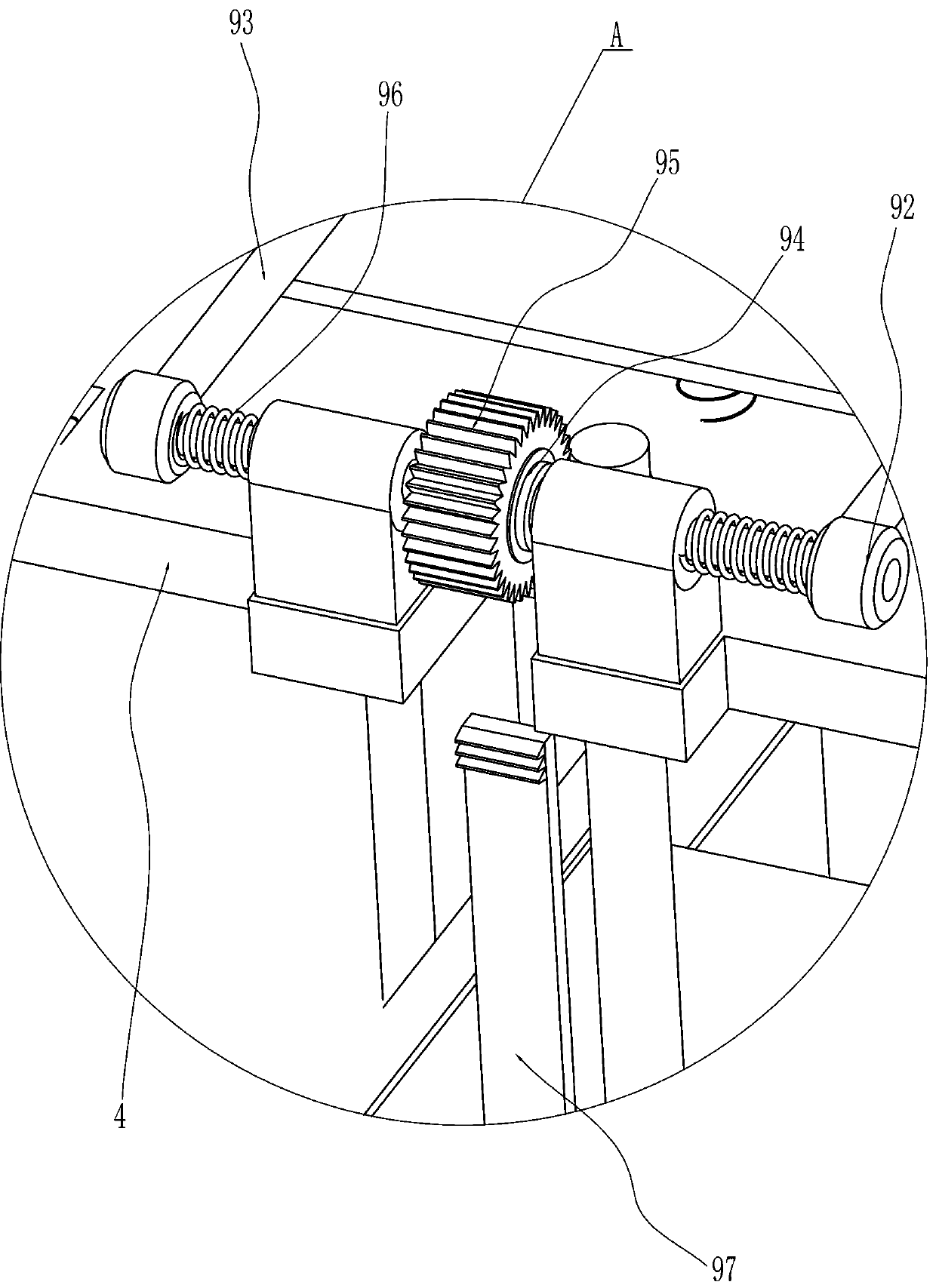

[0027] A red phosphorus adhesion device for match head processing, such as Figure 1-6 As shown, it includes a workbench 1, a guide rod 2, a compression spring 3 and a slide plate 4. Both sides of the top of the workbench 1 are connected with guide rods 2, and a slide plate 4 is slidably connected between the guide rods 2 on both sides. A compression spring 3 is connected between the worktables 1, and the compression spring 3 is sleeved on the guide rod 2, and also includes a pressure plate 5, an elastic member 6, a feeding assembly 7, a clamping assembly 8 and a smashing assembly 9, and the sliding plate 4 slides There is a pressure plate 5 connected in the same way, and an elastic member 6 is connected between the pressure plate 5 and the slide plate 4. There is smashing component 9.

[0028] The feeding assembly 7 includes a mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com