High-temperature-resistant high-strength underground cross-linked gel profile control agent as well as preparation method and application thereof

An underground cross-linking and profile-modifying agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the difficulties of injection of traditional polymer jelly and pre-cross-linked particles, poor deep effective plugging ability, sealing Insufficient plugging strength and other problems, to achieve the effect of improving the water absorption profile, prolonging the gelation time, and ensuring the safety of production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

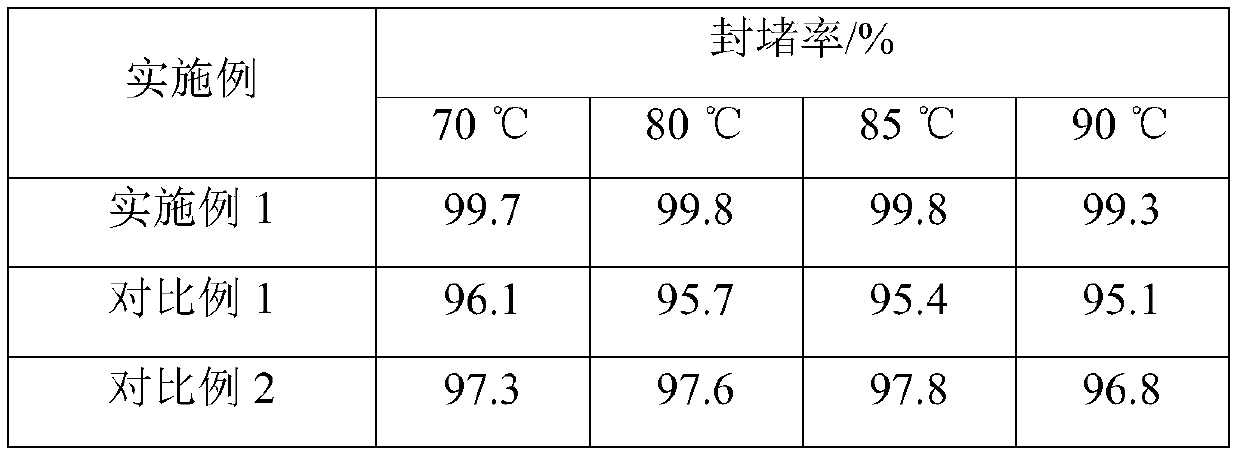

Examples

Embodiment 1

[0029] A high-temperature-resistant and high-strength underground cross-linked jelly profile control agent, comprising the following raw materials in mass percentage:

[0030] Acrylamide 5%, 2-acrylamido-2-methylpropanesulfonic acid 0.5%, sodium montmorillonite 2%, N,N-methylene bisacrylamide 0.044%, tert-butyl hydroperoxide 0.06 %, sodium hydroxide 0.3%, and the balance is water.

[0031] The preparation method of the above-mentioned high-temperature-resistant and high-strength underground cross-linked jelly profile control agent includes the following steps:

[0032] Weigh sodium-based montmorillonite and add it to a 250mL beaker filled with water, stir it with a mixer for 7 hours to make it evenly dispersed in water, and then mix acrylamide, 2-acrylamide- 2-Methylpropanesulfonic acid, N, N-methylenebisacrylamide and tert-butyl hydroperoxide aqueous solution prepared in advance with a mass concentration of 2% were sequentially added to the solution, stirred for 20 minutes, ...

Embodiment 2

[0035] A high-temperature-resistant and high-strength underground cross-linked jelly profile control agent, comprising the following raw materials in mass percentage:

[0036] Acrylamide 5%, 2-acrylamido-2-methylpropanesulfonic acid 0.8%, sodium montmorillonite 2%, N,N-methylene bisacrylamide 0.03%, tert-butyl hydroperoxide 0.06% , 0.3% sodium hydroxide, and the balance is water.

[0037] The preparation method of the above-mentioned high-temperature-resistant and high-strength underground cross-linked jelly profile control agent is as described in Example 1.

[0038] The initial viscosity of the high-temperature-resistant and high-strength underground cross-linked jelly profile control agent prepared in this example is 13 Pa·s.

Embodiment 3

[0040] A high-temperature-resistant and high-strength underground cross-linked jelly profile control agent, comprising the following raw materials in mass percentage:

[0041] Acrylamide 6%, 2-acrylamido-2-methylpropanesulfonic acid 0.5%, sodium montmorillonite 2%, N,N-methylene bisacrylamide 0.044%, tert-butyl hydroperoxide 0.06% , 0.3% sodium hydroxide, and the balance is water.

[0042] The preparation method of the above-mentioned high-temperature-resistant and high-strength underground cross-linked jelly profile control agent is as described in Example 1.

[0043] The initial viscosity of the high-temperature-resistant and high-strength underground cross-linked jelly profile control agent prepared in this example is 14 Pa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial viscosity | aaaaa | aaaaa |

| Initial viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com