A method of enhancing oil recovery using salt-sensitive self-thickening polymer

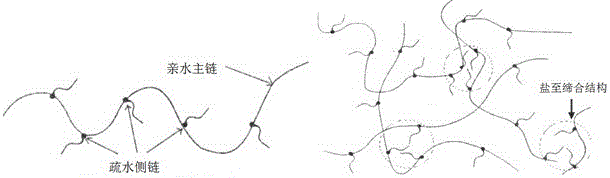

A self-thickening, polymer technology, which is applied in drilling compositions, chemical instruments and methods, and production fluids, etc., can solve the problem of difficulty in controlling the gel strength during freezing time and the depth of entry into the formation, and the effects of profile control and water shutoff. Weak, polymer solution viscosity drops and other problems, to achieve the effect of selective environmental friendliness, expanding the swept volume of water flooding, and reducing the water-oil mobility ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

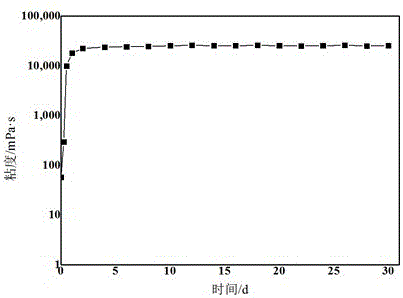

[0048] The method of using salt-sensitive self-thickening polymer to control the dominant channel to improve oil recovery in Example 1 of the present invention is to slowly add 0.25 g of salt to the brine with a salinity of 60000 mg / L and a mass of 99.75 g while stirring Sensitive self-thickening polymer, mechanically stirred for 30-40min, then left to mature for 0.5-1.0h to obtain a 0.25% salt-sensitive self-thickening polymer solution, which was then placed in a 60°C thermostat. DV-Ⅱ Pro viscometer measures the change of viscosity of salt-sensitive self-thickening polymer solution system with time (such as figure 2 shown).

[0049] The polymer solution in Example 1 of the present invention had a thickening effect, and the viscosity of the system increased significantly.

Embodiment 2

[0051] The method for improving oil recovery by using salt-sensitive self-thickening polymer to control the dominant channel in Example 2 of the present invention is based on the evaluation index of the plugging rate of the rock core. The greater the plugging rate, the better the ability to control the dominant channel. OK, the operation steps are:

[0052] Three sand-packing pipes with a length of 20cm and an inner diameter of 2.5cm were filled with sand to prepare simulated cores, which were respectively recorded as No. 1, No. 2 and No. 3. After water flooding until the pressure was stable, the permeability before plugging was measured. k 1 ; Then inject 0.3 V p The (core pore volume) mass fraction is 0.25%, and the salinity of the dosing water is 60000mg / L salt-sensitive self-thickening polymer solution (the viscosity of the system can be increased from the initial 45mPa·s to 24000mPa·s after aging at 60°C for 5 days), Subsequent injection of 0.05 V p The water is over...

Embodiment 3

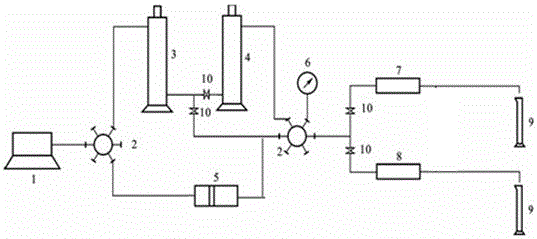

[0057] Example 3 of the present invention utilizes salt-sensitive self-thickening polymer to control the dominant channel to enhance the oil recovery method, which adopts a double-pipe sand-filled pipe core model (see Figure 4 ) to simulate heterogeneous formations with dominant channels, and then judge the ability of the salt-sensitive self-thickening polymer solution to regulate the dominant channels and the value of the oil recovery.

[0058] The implementation condition of the embodiment of the present invention 3 is:

[0059] The mass fraction of the salt-sensitive self-thickening polymer solution is 0.25%, and the salinity of the dosing water is 60000mg / L.

[0060] The above-mentioned salt-sensitive self-thickening polymer solution was used to carry out indoor core displacement experiments. The crude oil was dehydrated and degassed crude oil on the ground, and its viscosity at 60°C was 180mPa·s; the salinity of the simulated brine was 60,000mg / L; the experimental temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com