Cross-stepped type slope surface treatment method for mine dump

A treatment method and technology for dumping sites, applied in botany equipment and methods, excavation, container cultivation, etc., can solve problems such as soil pollution, soil erosion, geological disasters, etc., and achieve the effect of avoiding natural disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

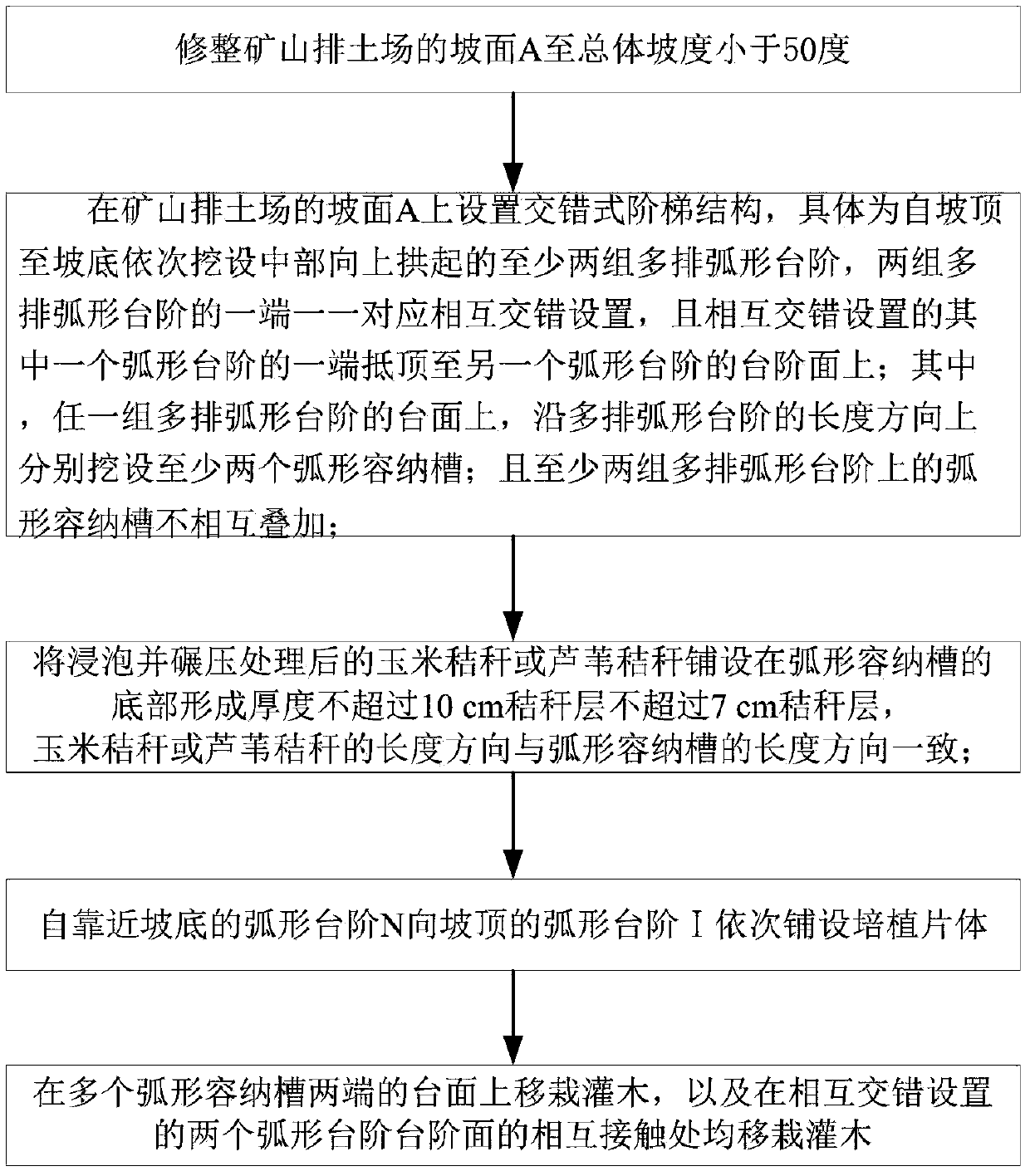

[0058] A cross-step slope treatment method for a mine dump, comprising the following steps:

[0059] Step 1, trimming the slope A of the mine dump 100 to an overall slope of 45 degrees;

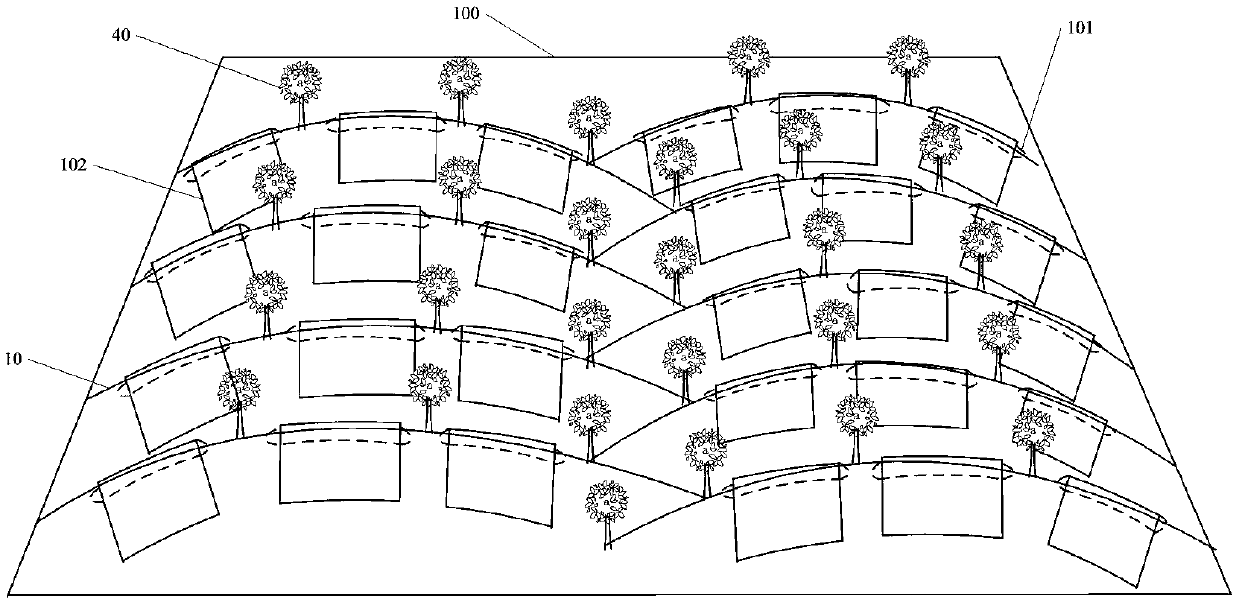

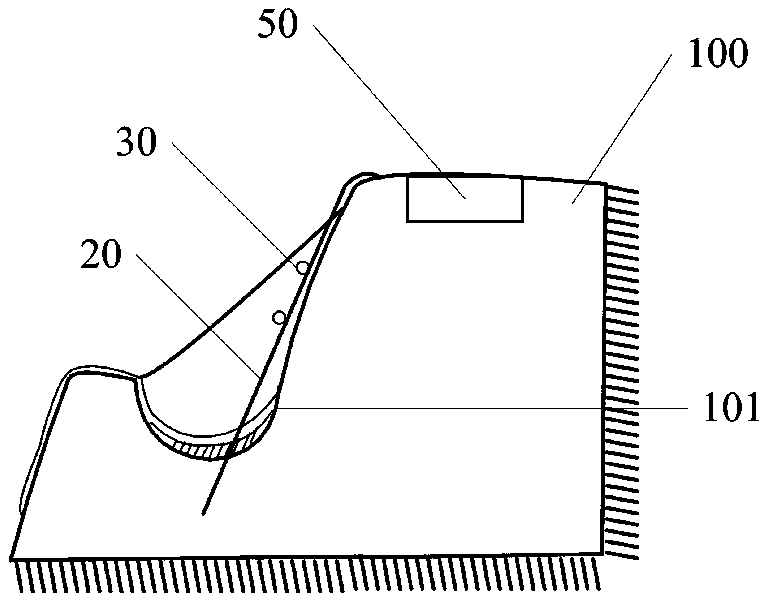

[0060] Step 2: Set up a staggered ladder structure on the slope A of the mine dump, specifically digging from the top of the slope to the bottom of the slope to set at least two sets of multiple rows of arc-shaped steps 10 that arch upwards in the middle, and two sets of multiple rows of arc-shaped steps 10. One end of the arc-shaped steps is arranged in a one-to-one correspondence with each other, and one end of one of the arc-shaped steps arranged in an interlaced manner abuts against the step surface of the other arc-shaped step; wherein, on any set of multiple rows of arc-shaped steps, At least two arc-shaped accommodation slots 101 are respectively dug along the length direction of multiple rows of arc-shaped steps; and at least two sets of arc-shaped accommodation slots on multiple rows...

Embodiment 2

[0075] A cross-step slope treatment method for a mine dump, comprising the following steps:

[0076] Step 1, trimming the slope A of the mine dump 100 to an overall slope of 40 degrees;

[0077]Step 2: Set up a staggered ladder structure on the slope A of the mine dump, specifically digging from the top of the slope to the bottom of the slope to set at least two sets of multiple rows of arc-shaped steps 10 that arch upwards in the middle, and two sets of multiple rows of arc-shaped steps 10. One end of the arc-shaped steps is arranged in a one-to-one correspondence with each other, and one end of one of the arc-shaped steps arranged in an interlaced manner abuts against the step surface of the other arc-shaped step; wherein, on any set of multiple rows of arc-shaped steps, At least two arc-shaped accommodation slots 101 are respectively dug along the length direction of multiple rows of arc-shaped steps; and at least two sets of arc-shaped accommodation slots on multiple rows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com