Municipal engineering fair-faced concrete pouring construction method

A technology of fair-faced concrete and construction methods, which is applied in the direction of construction, building structure, and construction material processing, and can solve problems such as single concrete materials, weak wall rigidity, and loss, so as to prevent surface subsidence and achieve good pouring effects , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

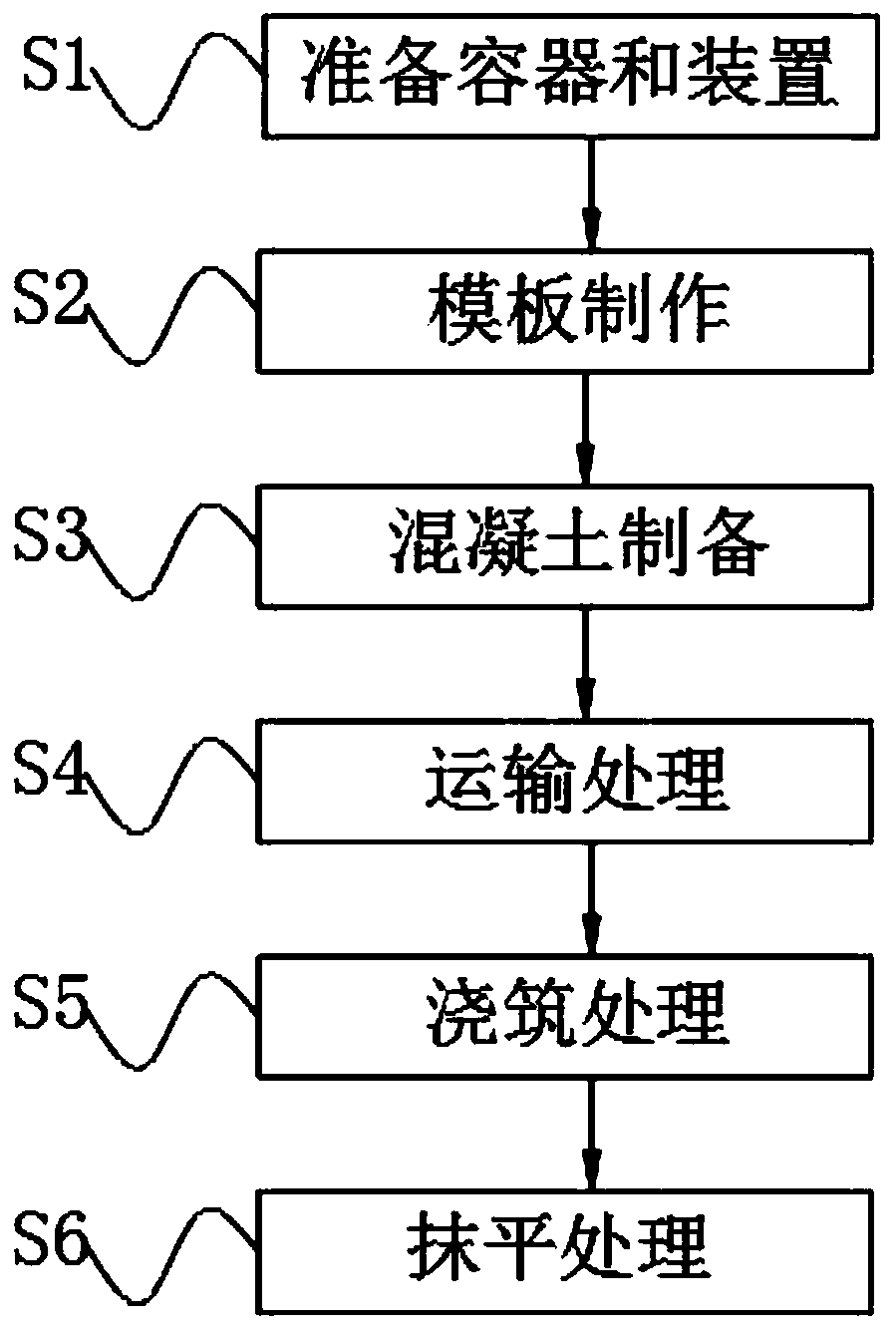

Image

Examples

Embodiment 1

[0027] S1. Prepare containers and devices: pre-clean multiple storage barrels, prepare stirring devices, grinders, vibrators, measuring rulers, levels and wooden trowels;

[0028] S2. Formwork production: use a grinder to grind the outer surfaces of multiple sub-formworks and rigid rods in advance. After the grinding is completed, wipe them clean with a rag, and weld multiple rigid rods with a quantitative width of 2cm on the outer surfaces of the sub-formworks. And the outer surface of the steel rod is pre-smeared with 1cm quantitative thickness of cement paint. After the application is completed, place it for 10 minutes, then apply 1cm quantitative thickness of anti-rust grease on the outer surface, and then place it for 10 minutes, and then pass the external measuring ruler and level. The sub-formwork with steel rods welded on the outer surface is assembled;

[0029] S3. Concrete preparation: prepare in advance 100 parts of water, 10 parts of admixture, 300 parts of sand, 2...

Embodiment 2

[0034] S1. Prepare containers and devices: pre-clean multiple storage barrels, prepare stirring devices, grinders, vibrators, measuring rulers, levels and wooden trowels;

[0035]S2. Formwork production: Use a grinder to grind the outer surfaces of multiple sub-formworks and rigid rods in advance. After the grinding is completed, wipe them clean with a rag, and weld multiple rigid rods with a quantitative width of 3cm on the outer surfaces of the sub-formworks. And the outer surface of the steel rod is pre-smeared with 1.5cm quantitative thickness of cement paint. After the application is completed, let it sit for 15 minutes, then apply 1.5cm quantitative thickness of anti-rust grease on the outer surface, and then leave it for 15 minutes, and then pass the external measuring ruler and level. , assemble the sub-formwork with steel rods welded on the outer surface;

[0036] S3. Concrete preparation: prepare in advance 125 parts of water, 13 parts of admixture, 320 parts of sand...

Embodiment 3

[0041] S1. Prepare containers and devices: pre-clean multiple storage barrels, prepare stirring devices, grinders, vibrators, measuring rulers, levels and wooden trowels;

[0042] S2. Formwork production: use a grinder to grind the outer surfaces of multiple sub-formworks and rigid rods in advance. After the grinding is completed, wipe them clean with a rag, and weld multiple rigid rods with a quantitative width of 5cm on the outer surface of the sub-formworks. And the outer surface of the steel rod is pre-smeared with cement paint with a quantitative thickness of 2cm. After the application is completed, place it for 20 minutes, then apply anti-rust grease with a quantitative thickness of 2cm on the outer surface, and then place it for 20 minutes, and then use the external measuring ruler and level. The sub-formwork with steel rods welded on the outer surface is assembled;

[0043] S3. Concrete preparation: prepare in advance 150 parts of water, 15 parts of admixture, 350 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com